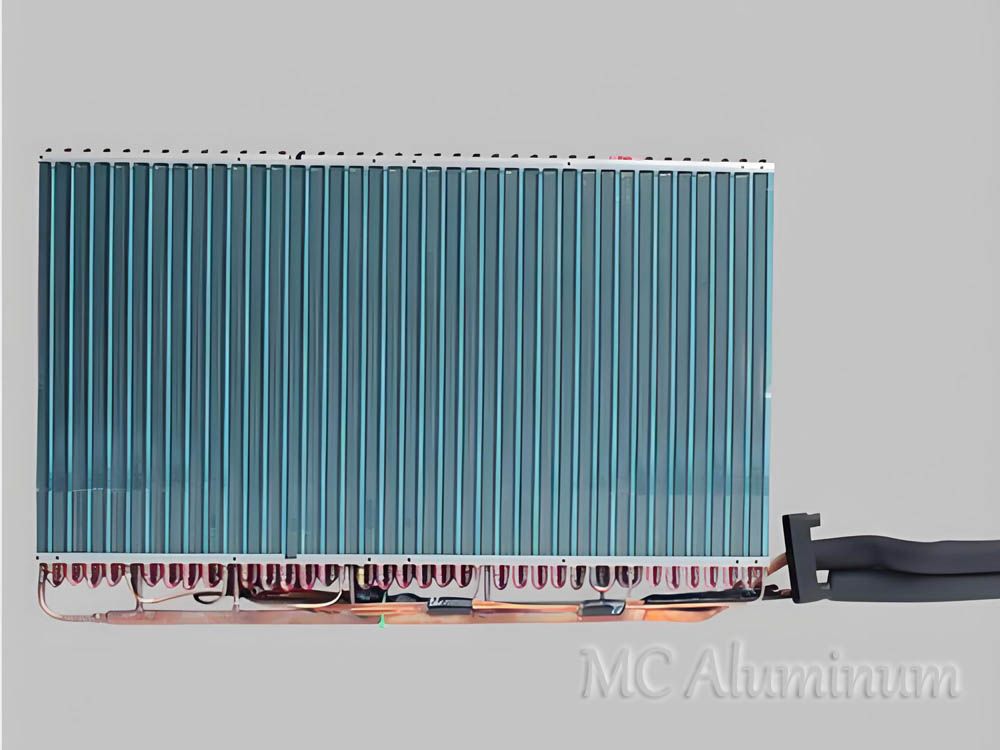

Blue Hydrophilic Coated Aluminum Foil for Air Conditioner Heat Exchangers

In the modern HVAC (Heating, Ventilation, and Air Conditioning) industry, deep blue hydrophilic coated aluminum foil stands out for its outstanding corrosion resistance, attractive appearance, and excellent water-shedding properties. This innovative material is specially designed for air conditioner fins, enhancing heat exchange efficiency, preventing oxidation, and ensuring long-term stability even in humid or coastal environments.

What Is Blue Hydrophilic Aluminum Foil?

Blue hydrophilic aluminum foil is an aluminum material with a blue surface coating. It is usually made from high-quality aluminum base material and processed through precision techniques. The blue coating not only provides a visually appealing appearance but, more importantly, enhances its hydrophilic properties.

With this coating, condensate no longer forms into droplets but instead spreads evenly into a thin water film that flows quickly along the fins. This transformation improves heat exchange efficiency by more than 5%, while also reducing energy consumption and operational noise in air conditioners.

Besides blue coating, MC Aluminum also offers hydrophilic foils in silver, red, gold, and black.

1. Silver is the natural color of aluminum fins.

2. Red resembles the appearance of copper, known for excellent heat conductivity.

3. Gold and black emphasize anti-corrosion performance, ideal for coastal or humid areas with high salt concentration in the air.

Hydrophilic aluminum foil for air conditioners is typically made from 1100, 3003, 3102, or 8011 alloys, with common thicknesses ranging from 0.10mm to 0.20mm.

Core Functions of the Hydrophilic Coating

Enhanced Hydrophilicity:

The main purpose of the coating is to reduce the surface tension of the aluminum foil, allowing water droplets to spread and flow easily. This feature makes blue hydrophilic foil valuable in many heat exchange applications.

Improved Corrosion Resistance:

Since aluminum is naturally reactive, the hydrophilic coating effectively isolates oxygen and moisture, slowing down the corrosion process and protecting the foil from environmental degradation.

Material Advantage:

The coating combines high-polymer compounds and nano-scale inorganic oxides, ensuring excellent film formation and adhesion. These materials are also cost-effective, helping reduce overall production costs and making the product more competitive in the market.

Extended Durability:

The special coating extends the fin's lifespan to 8–10 years, maintaining performance even in harsh operating conditions.

Technical Specifications of Blue Hydrophilic Aluminum Foil

| Alloy | 1100, 3003, 3102, 8011 |

| Temper | O, H22, H24 |

| Thickness | 0.08mm - 0.20mm |

| Width | 200mm - 1400mm |

| Length | Customizable |

| Color | Deep Blue |

| Coating Type | Hydrophilic, epoxy resin, anti-corrosion |

| Coating Thickness | 3-8 μm per side |

| Adhesion Test | No peeling after tape test |

| Corrosion Resistance | >1000 hours salt spray test |

| Water Contact Angle | ≤ 30° |

| Elongation | ≥ 15% |

| Tensile Strength | 120-160 MPa |

| Performance | Stable hydrophilic and anti-corrosion performance (R.NO ≥ 9.8 after 500h 5% NaCl test) |

| Applications | AC heat exchangers, outdoor condenser fins, automotive air conditioning systems |

| MOQ | 1-3 tons |

Key Performance Advantages

1. Hydrophilicity:

The coating allows condensate to spread uniformly over the surface, forming a thin film that drains away quickly. This prevents moisture accumulation and improves overall heat exchange efficiency.

2. Corrosion Resistance:

The hydrophilic and anti-corrosion coating shields the aluminum substrate from acid, salt mist, and oxidation, extending product lifespan-especially beneficial in coastal and humid climates.

3. Enhanced Heat Dissipation:

By reducing "water bridges" and accelerating drainage, the coating maintains stable airflow, ensuring efficient and consistent heat transfer.

4. Anti-Mold Properties:

The surface treatment inhibits microbial growth, ensuring cleaner and healthier air output.

5. Aesthetic Appeal:

The deep blue finish provides a sleek, modern appearance, making it an ideal choice for premium air conditioner brands. It also helps distinguish high-quality coils and adds a touch of visual sophistication.

6. Environmental Safety:

The coating formulation is non-toxic and RoHS-compliant, ensuring safety during production and usage.

Applications of Hydrophilic Aluminum Foil in Air Conditioning

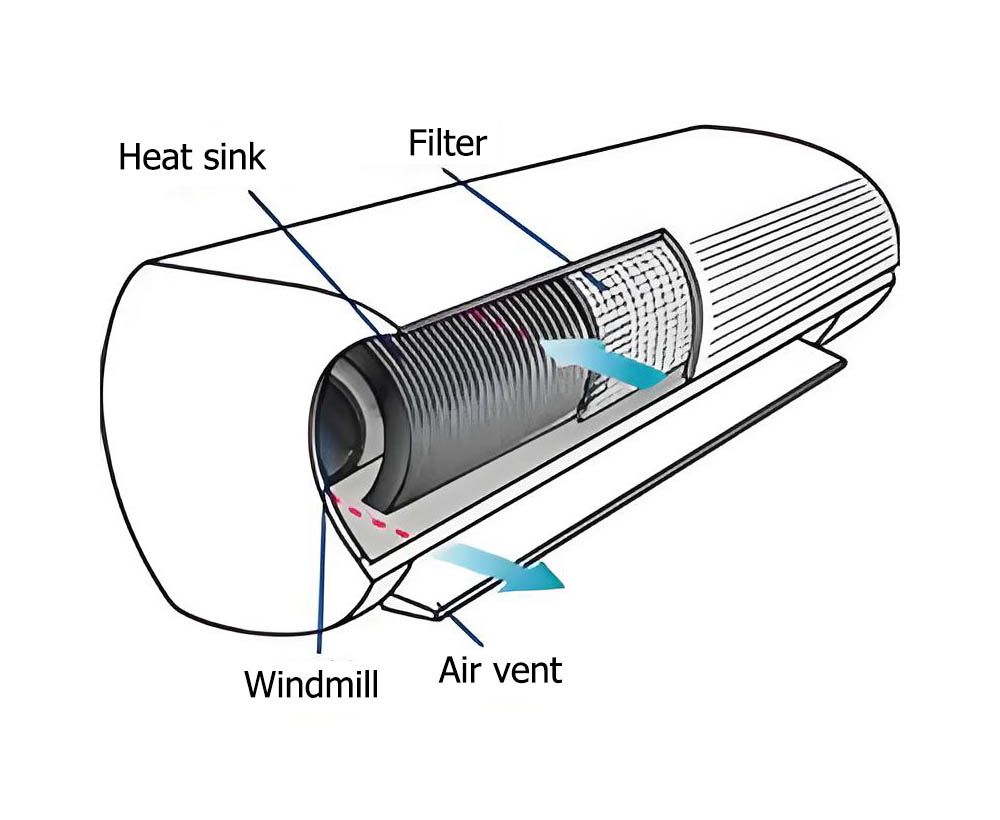

Evaporator Fins:

Facilitates rapid drainage of condensate and prevents frosting.

Condenser Fins:

Ensures efficient heat dissipation even when the outdoor unit is exposed to moisture, dust, or salt air.

Automotive Air Conditioning Systems:

Enhances thermal performance and prevents corrosion in challenging road and weather conditions.

Dehumidifiers and Cooling Equipment:

Minimizes water droplet adhesion, maintaining long-term energy efficiency.

Split and Window Air Conditioners:

Improves unit lifespan and ensures consistent cooling performance.

Are Blue Hydrophilic Fins More Energy-Efficient?

Yes. Air conditioners equipped with blue hydrophilic coated fins are more energy-efficient due to the coating's superior water-shedding and anti-fouling properties.

The energy consumption of an air conditioner depends largely on its heat exchange efficiency. When condensate accumulates as water droplets (forming "water bridges") on the evaporator, airflow is blocked, and the compressor must work harder to achieve the same cooling performance - resulting in wasted energy.

The deep blue hydrophilic coating contributes to energy savings in several ways:

1. Reduced Airflow Resistance:

Hydrophilicity ensures condensate quickly forms a thin film and drains away, minimizing droplet obstruction between fins. Smoother airflow means the fan consumes less power while maintaining efficient cooling.

2. Sustained Heat Exchange Efficiency:

By preventing water bridges, the coating allows the heat exchanger to operate at its full design capacity. High heat transfer efficiency shortens compressor operation time, directly lowering energy consumption.

3. Long-Term Stability:

The blue anti-corrosion layer protects fins from environmental oxidation and dust accumulation. Uncoated aluminum fins degrade over time, leading to higher power usage. The blue coating maintains efficiency throughout the air conditioner's lifespan, ensuring consistent energy savings.

Thus, blue aluminum fins are recognized as a hallmark of high efficiency and low energy loss, representing the latest in hydrophilic anti-corrosion technology.

Contact Us