Hydrophilic Aluminum Foil for Air Conditioners 1100 / 1030B / 3102 / 8011

In modern air conditioning systems, aluminum fins are one of the key components of heat exchangers, including evaporators and condensers. To improve heat transfer efficiency, prevent condensation accumulation, and resist corrosion, manufacturers commonly use a special material called hydrophilic aluminum foil.

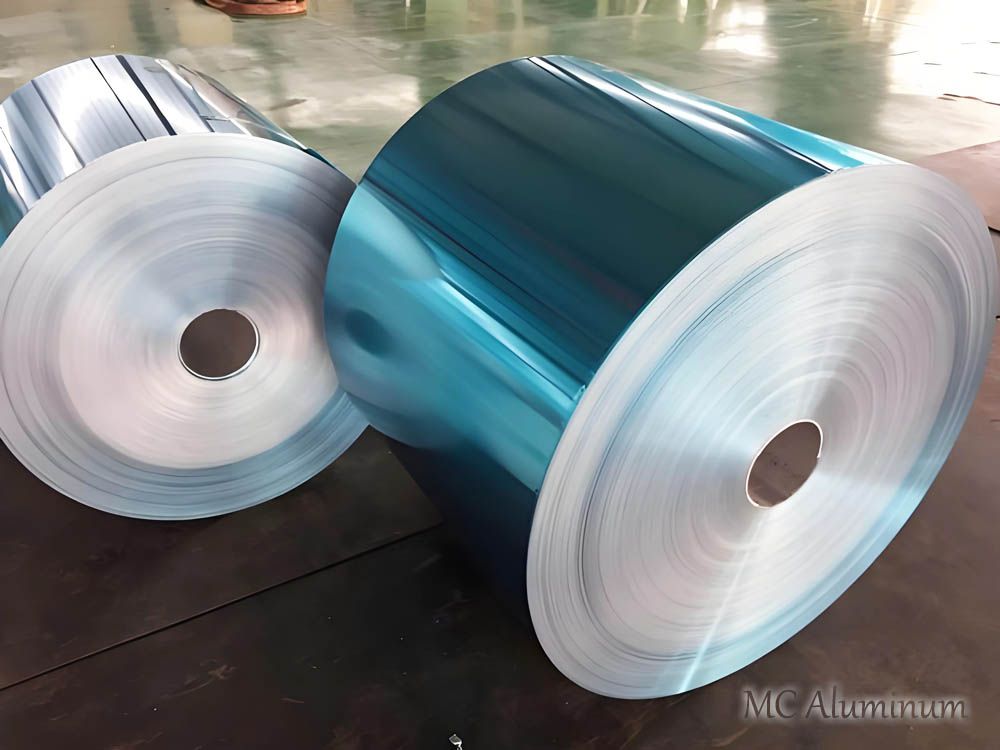

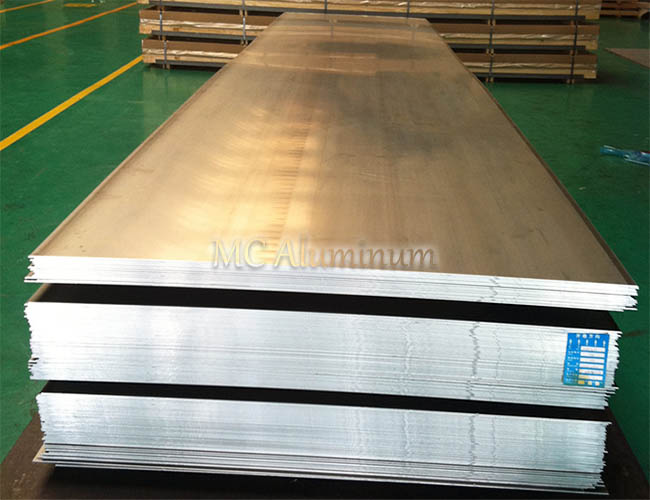

Hydrophilic aluminum foil is the core material for efficient heat exchange, directly affecting the air conditioner's cooling efficiency, energy consumption, and lifespan. This ultra-thin foil, typically 0.1-0.15 mm thick, is treated with a special hydrophilic coating. This allows condensate water to quickly spread into a thin film and flow away, reducing noise, improving heat transfer efficiency, and preventing water bridges or frost blockages between fins.

Common Alloys for Air Conditioner Hydrophilic Aluminum Foil

The main alloys used in AC hydrophilic aluminum foil are 1100, 1030B, 3102, and 8011.

1100 Aluminum Foil:

Part of the industrial pure aluminum series, 1100 aluminum foil has excellent formability, high thermal conductivity, good flatness, and strong coating adhesion. It is widely used in air conditioning heat exchangers, and its high thermal conductivity ensures superior heat transfer efficiency.

1030B Aluminum Fin Foil:

Another pure aluminum alloy, 1030B features good corrosion resistance and uniform microstructure. Often combined with other alloys, it provides stable performance in specific environments and serves as a foundational material for high-quality hydrophilic foil.

3102 Aluminum Foil:

Specifically developed for AC fins, 3102 alloy offers good mechanical properties and excellent deep-drawing performance, making it popular in the high-end air conditioning market.

8011 Hydrophilic Aluminum Foil:

The most widely used hydrophilic foil in the AC market, 8011 is an aluminum-iron alloy with an iron content of 0.7%-1.5%, offering excellent corrosion resistance and good processing performance.

Specifications of Hydrophilic Aluminum Foil

| Alloys | 1100, 1030B, 3102, 8011, etc. |

| Temper | O, H14, H16, H22, H24, H26, etc. |

| Thickness | 0.09-0.20 mm |

| Width | 100-1400 mm |

| Length | 100-6000 mm |

| Surface Coating | Blue, gold, transparent, green (customizable) |

| Coating Adhesion | 5B (no peeling in cross-cut test) |

| Humidity & Heat Resistance | No corrosion spots after 1000 hours |

| Alkali Resistance | No change after 30 min immersion in NaOH |

| Mold Resistance | No mold growth after 28 days |

| Temperature Resistance | -40°C to 120°C |

| Bending Performance | 180° bend without cracking |

Working Principle of Hydrophilic Aluminum Foil

During AC operation, condensate forms on the surface of evaporator fins due to low temperatures. On ordinary aluminum foil, water forms droplets, which obstruct airflow, increase noise, and reduce efficiency. Hydrophilic aluminum foil, however, forms a thin water film that allows smooth airflow, ensuring continuous and efficient heat exchange.

Key Advantages of Hydrophilic Aluminum Foil

1. Corrosion Resistance:

Surface coatings prevent oxidation and corrosion, extending the lifespan of air conditioners.

2. Prevents Water Bridges:

Avoids droplet bridges that obstruct airflow, reducing energy consumption.

3. Improves Heat Transfer Efficiency:

Can save 10-15% energy, enabling faster and more efficient cooling.

4. Mold and Bacteria Resistance:

Quick drainage reduces moisture accumulation, suppressing bacterial growth.

5. Noise Reduction:

Smooth water flow lowers operational noise.

Applications in Air Conditioning Systems

Residential and Central Air Conditioners:

Hydrophilic foil prevents water droplet buildup, improves airflow, and ensures long-term stable operation.Dehumidifiers and Air Purifiers:

Enables rapid condensation drainage, keeping systems dry and preventing odors.Automotive Air Conditioning:

Provides excellent vibration and moisture resistance, ensuring durable heat exchangers.Cold Storage, Refrigerators, and Industrial Cooling:

Offers superior corrosion resistance, suitable for long-term use in humid environments.

Application Value in Air Conditioning

Enhances Overall AC Performance:

Air conditioners using high-quality hydrophilic foil maintain more stable outlet air temperatures over 30 days of continuous operation, reducing electricity consumption by 10-15%. This is especially important in the context of rising energy costs.

Adapts to Harsh Environments:

In high-temperature, high-dust industrial environments, hydrophilic foil demonstrates strong adaptability. For example, patent CN201126243Y describes a special air conditioner using hydrophilic foil on evaporator and condenser fins with increased fin spacing (2.0 mm for the condenser, 3.0 mm for the evaporator), effectively preventing condensation and dust blockage under harsh conditions.

Extends AC Lifespan:

Ordinary aluminum fins often show oxidation, darkening, or perforation after several years of use. In contrast, 8011 hydrophilic foil fins remain nearly new under the same conditions, greatly extending the air conditioner's service life and reducing maintenance costs.

Contact Us