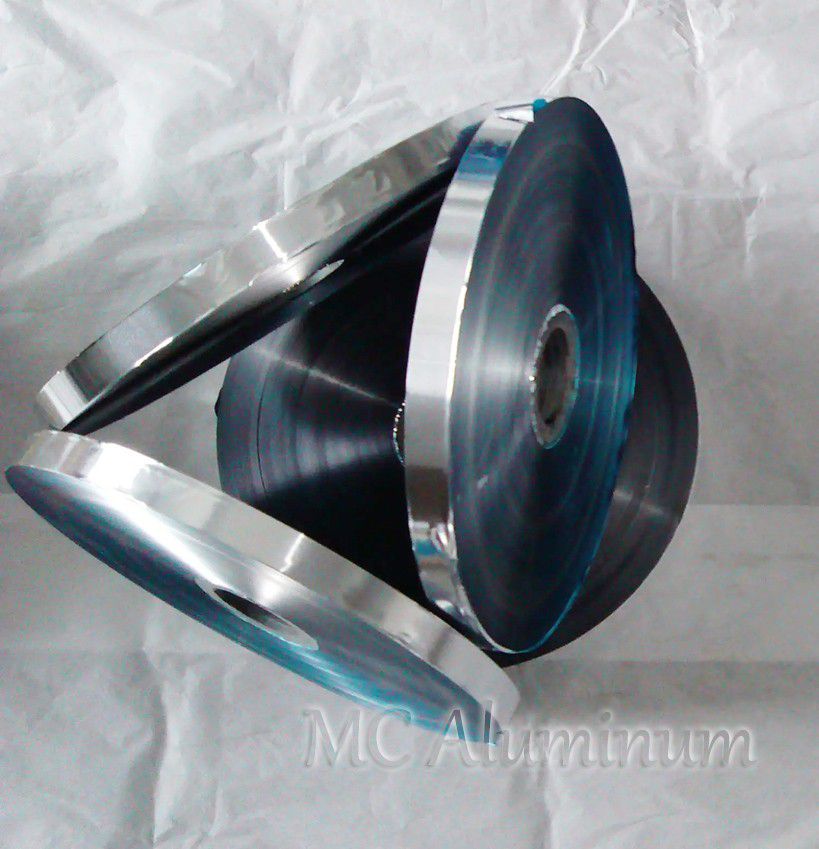

0.11-0.2mm 8011 1060 O-state aluminum foil for cable covering

With the rapid development of the national economy, the demand for aluminum foil materials for cables at home and abroad is also rising at an alarming rate, especially communication cables and optical fiber cables.

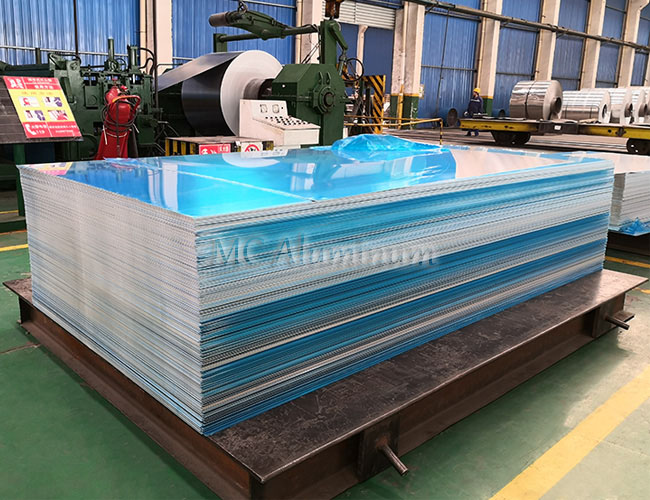

Aluminum foil for cable coating is a key cable shielding and protection material. Its excellent shielding performance and protective characteristics make it widely used in communications, electric power, automobiles and other fields. Choosing the appropriate aluminum foil coating material and coating method can significantly improve the performance and reliability of the cable. Cable foil usually uses 8011 aluminum foil and 1060 aluminum foil as raw materials. The tempering state is O state. The thickness range is 0.11-0.2mm. The length and width can be customized according to customer needs.

Cable aluminum foil tape specifications:

| Alloy | 8011 1060 |

| Temper | O |

| Thickness | 0.11~0.2mm(thickness tolerance±0.01) |

| Width | 100-1700mm (width tolerance ±1mm) |

| Length | 100-16000mm |

| ID | 75/150/300mm |

| Tensile strength | 90~105Mpa |

| Elongation | >25% |

| Packing | export standard, covering with brown paper and plastic film then packed with wooden case/pallet |

| Port | Qingdao,Ningbo,Tianjin,Shanghai,etc |

Advantages of aluminum foil for cable coating:

1. It has good electromagnetic shielding performance and can block electromagnetic interference and radio frequency interference.

2. Provide good physical protection to prevent cable damage, moisture and chemical corrosion.

3. High temperature resistance, suitable for cable applications in high temperature environments.

3. It has good flexibility and is easy to cover on the surface of the cable, making it easy to process and install.

4. Lightweight, does not increase the weight of the cable, and is easy to transport and install.

5. Good corrosion resistance can resist erosion from the external environment.

Covering method

1. Single-sided covering: Aluminum foil covers only one side of the cable, usually used in applications that do not require complete shielding.

2. Double-sided coating: Aluminum foil is wrapped on both sides of the cable to provide stronger shielding and protection.

3. Composite coating: Aluminum foil is used in combination with other materials (such as plastics, fibers, etc.) to enhance the comprehensive performance of the coating layer.

Contact Us