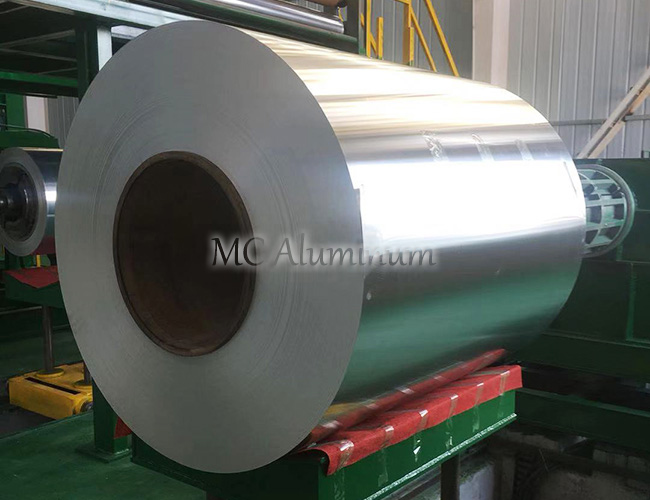

3102 H22 Air Conditioning Aluminum Foil Jumbo Rolls

3102 air conditioning aluminum foil is a key raw material used in modern air conditioning and refrigeration equipment, such as evaporators and condensers, for manufacturing fins (heat dissipation plates). Belonging to the aluminum-manganese alloy series, it features excellent heat transfer efficiency, formability, and corrosion resistance due to its specific alloy composition and precise rolling and heat treatment processes. It serves as the foundational material ensuring the efficient and stable operation of air conditioning systems.

3102 aluminum alloy is part of the Al-Mn series, offering higher strength and hardness than 1xxx series pure aluminum. The H22 temper indicates that the material has undergone work hardening and partial annealing, achieving a semi-hard state that balances sufficient strength with good formability. This ensures that fins made from 3102 foil resist cracking during high-speed stamping while maintaining adequate mechanical strength to withstand vibration and pressure during operation.

Performance Advantages of 3102 AC Aluminum Foil

1. Moderate Strength

H22 temper provides slightly higher strength than O temper (soft state) while maintaining good stamping and stretching performance. Ideal for forming thin-walled fins without cracks or wrinkles.

2. High Thermal Conductivity

Thermal conductivity reaches 200-230 W/m·K, improving heat exchange efficiency and reducing energy consumption.

3. Excellent Corrosion Resistance

The Mn content in 3102 significantly enhances corrosion resistance, especially under condensate water or refrigerant exposure.

4. Strong Surface Treatment Compatibility

Compatible with hydrophilic coatings, hydrophobic coatings, and anti-corrosion treatments, extending heat exchanger lifespan and preventing oxidation.

5. Recyclable and Environmentally Friendly

3102 aluminum foil is 100% recyclable, meeting green manufacturing and energy-saving requirements.

6. Uniform Material Properties

3102 H22 AC aluminum foil exhibits uniform microstructure and performance, with minimal metallurgical defects and low anisotropy. Even in ultra-thin gauges, it maintains excellent formability.

Specifications of 3102 AC Aluminum Foil

| Alloy | 3102 |

| Temper | H22 (semi-hard) |

| Thickness | 0.08-0.20 mm |

| Width | 200-1500 mm |

| Length | Customizable |

| Tensile Strength | 130-170 MPa |

| Elongation | ≥15% |

| Thermal Conductivity | ≥200 W/m·K |

| Color | Blue, Gold, Green, etc. |

| Surface Treatment | Bright, hydrophilic, coated, anti-corrosion |

| Surface Quality | No oil stains, no impressions, no wrinkles, no pinholes |

| Roll Weight | 500-2000 kg (jumbo roll) |

| ID | 76/152 mm |

| OD | 300-1600 mm |

| Applications | Radiators, heat exchanger coils, condenser coils, evaporator coils, air coolers, AC systems |

| MOQ | 1-3 tons |

Main Application Areas of 3102 H22 AC Aluminum Foil

1. Air Conditioning Heat Exchanger Fins

This is the most typical application. 3102 H22 foil is used for condenser and evaporator fins, offering excellent thermal conductivity and formability, and maintaining stability under high-frequency thermal cycles.

2. Automotive AC Systems

Automotive air conditioning requires materials with good strength and corrosion resistance under high-temperature vibration. 3102 aluminum foil provides structural stability and durability.

3. Heat Pumps and Refrigeration Equipment

In heat pumps, refrigerators, and freezers, 3102 foil is used for heat exchanger plates and condenser layers, enhancing energy efficiency.

4. Hydrophilic Aluminum Foil

Hydrophilic-coated 3102 H22 foil forms a uniform water film on its surface, reducing condensate adhesion, improving heat exchange efficiency, and preventing "dripping noise."

5. Anti-Corrosion Coated Aluminum Foil

Suitable for air conditioners used in coastal or humid environments, providing excellent salt-spray corrosion resistance and extending equipment lifespan.

Why Choose MC Aluminum 3102 Jumbo Rolls?

Large Roll Widths & High Continuous Production Efficiency

Single rolls up to 2 tons reduce roll changes, meeting high-speed automated heat exchanger production line requirements.Excellent Surface Flatness

No oil stains, bubbles, or pinholes, ensuring uniform heat dissipation after fin forming.Strong Coating Adhesion

Hydrophilic or anti-corrosion coatings adhere well without peeling, maintaining performance.Stable Production

Advanced rolling and annealing processes ensure thickness tolerance within ±3%.Energy Saving & Environmentally Friendly

Fully recyclable and compliant with RoHS and REACH standards, supporting green AC manufacturing.

Production Process of 3102 AC Aluminum Foil

Aluminum Ingot Casting → Hot Rolling → Cold Rolling → Annealing → Surface Cleaning → Coating or Hydrophilic Treatment → Slitting → Jumbo Roll Winding

The process requires precise temperature control and surface quality management. Key factors determining product grade include pinhole rate, thickness deviation, and surface cleanliness.

Quality Control Parameters

Pinhole density ≤ 3 per m²

Thickness deviation ≤ ±3%

Residual oil ≤ 0.02 g/m²

Peeling strength ≥ 10 N/cm (hydrophilic coating)

FAQ

Q1: Why are AC fins mostly made of 3102 H22 aluminum foil?

A1: 3102 alloy offers high thermal conductivity, moderate strength, and good corrosion resistance, while H22 temper balances workability and mechanical performance, making it ideal for thin-walled fin stamping.

Q2: What advantages does 3102 H22 foil have over 3003 H24?

A2: 3102 provides better thermal conductivity, lower density and weight, superior corrosion resistance, and stronger coating adhesion, especially suitable for hydrophilic aluminum applications.

Q3: What is the difference between H22 and H24 tempers?

A3: H22 is semi-hard with slightly lower strength but better ductility, ideal for forming. H24 is harder, stronger, but slightly less suitable for stamping.

Q4: What surface treatments can 3102 aluminum foil undergo?

A4: Hydrophilic coatings, anti-corrosion coatings, hydrophobic coatings, and anti-mold/antibacterial treatments to meet various climate and environmental requirements.

Q5: How to judge whether the foil surface quality is acceptable?

A5: The surface should be free of pinholes, impressions, oil stains, or scratches; surface smoothness ≥85%; pinhole rate ≤3 per m², meeting AC industry standards.

Q6: Can 3102 foil replace 8011 aluminum foil?

A6: Not suitable in packaging, but in heat exchanger applications, 3102 offers better thermal conductivity and corrosion resistance, making it superior.

Contact Us