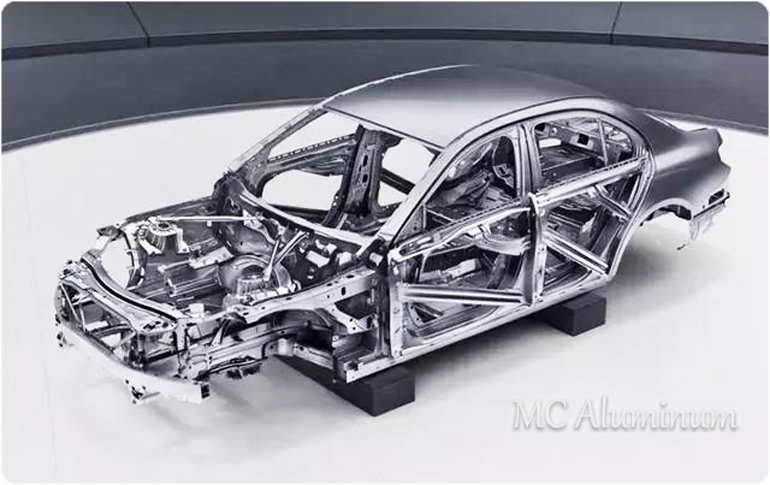

5052 Aluminum sheet for automobile skin

Environmental protection is an unavoidable topic today. Regardless of whether it is a traditional fuel vehicle or a new energy vehicle, lightweight bodywork is an inevitable requirement. Aluminum-magnesium alloys have won over the automotive industry for their light weight, relatively low cost, and many desirable properties.

The automotive industry has very strict requirements for components, and the selection of materials is also very strict. Material safety is very important. Many components must be ductile to absorb energy during impact, while other components must have strength to maintain structural rigidity. And aluminum alloy is the best choice.

What are the advantages of using 5052 aluminum alloy for automobile skin?

1. Light weight. The 5052 aluminum plate has a higher strength-to-weight ratio than low-carbon steel. With the reduction in weight, fuel consumption and exhaust emissions will be relatively reduced, which is beneficial to the environment.

2. High security. 5052 aluminum plate has excellent performance, high ductility, durability and high safety.

3. Recyclable. 5052 aluminum plate can be recycled to reduce carbon emissions.

MC Aluminum is a large-scale manufacturer of automotive aluminum sheets, integrating R&D, production and sales, with advanced equipment and mature technology. The company's product specifications are complete, with a width of 2600mm, which can be customized according to customer needs, with huge production capacity, fast delivery, and guaranteed after-sales service. If you want to know any details about aluminum sheet products, welcome to contact us immediately. Contact us via the message form below or email: sales@alummc.com. Our sales staff will get back to you as soon as possible.

Contact Us