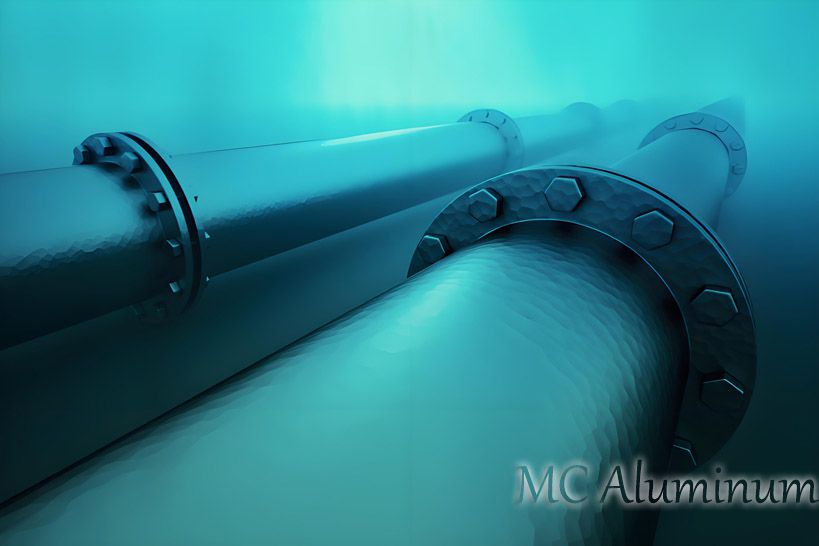

5454 aluminum sheet for marine facility pipelines

In marine engineering and facility construction, the choice of materials is directly related to the long-term stability and reliability of the system. Faced with high-salt, high-humidity and highly corrosive marine environments, 5454 aluminum sheet has become an ideal material choice for marine facility pipelines due to its excellent corrosion resistance, medium strength and good welding performance. In particular, 5454-H112 aluminum sheet, its performance has been optimized to meet the stringent requirements of marine pipelines under complex working conditions.

Introduction to 5454 aluminum sheet

5454 aluminum sheet for marine facility pipelines is one of the advantageous products of MC Aluminum. The 5454 aluminum sheet produced by MC Aluminum has sophisticated craftsmanship and can adapt to harsh corrosive environments. It is a typical rust-proof aluminum with high strength, which is about 20% higher than 5052 aluminum sheet. The product quality meets national standards and provides original factory warranty. 5454 aluminum sheet is widely used in automobiles, aluminum tank truck cylinders and other fields, and has a good reputation.

Compared with 5052-H32 aluminum sheet or 5083-H112 marine aluminum sheet, 5454-H112 is more suitable for marine facility applications in terms of corrosion resistance and high temperature resistance, especially for environments with high requirements for pipeline systems.

Introduction to H112 state

H112 state is a process state of aluminum alloy, which means that the material is formed by cold working in a state close to annealing, with a certain work hardening effect, but still maintains high plasticity and good mechanical properties.

5454 aluminum sheet in H112 state has both strength and processing performance, which is very suitable for marine engineering applications that require forming and welding.

5454 aluminum sheet has many advantages for marine facility pipelines:

1. Strong corrosion resistance: 5454 aluminum sheet has high seawater corrosion resistance and is suitable for long-term use in marine environments.

2. Higher strength: Compared with 5052 aluminum sheet, 5454 aluminum sheet has higher strength, but still maintains good ductility and processing performance.

3. Good welding performance: 5454 aluminum sheet has excellent welding performance, especially suitable for pipelines, storage tanks and other scenes that require welding.

4. Excellent high temperature resistance: It can maintain performance at temperatures up to 150°C, suitable for environments that are sensitive to temperature changes.

Typical alloy 5454 aluminum sheet:

| Alloy | 5454 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34H36, H38, H111, H112, H114, H116, H321 |

| Thickness | 3-50mm |

| Width | 20-2650 |

| Length | 500-16000 |

| Typical product uses | lightweight automobiles, fuel tank materials, tanker tanks, insulation pipes, tanker cylinders, marine facility pipes, automobile wheels, etc. |

Chemical composition of 5454 marine grade aluminum sheet

| Element | Content (%) |

| Mg | 2.4-3.0 |

| Mn | 0.5-1.0 |

| Fe | ≤0.40 |

| Si | ≤0.25 |

| Cu | ≤0.10 |

| Cr | ≤0.25 |

| Zn | ≤0.25 |

| Al | remainder |

Mechanical properties of 5454-H112 aluminum sheet

| Performance index | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| value | 215–280 | ≥125 | 12–20 |

5454 aluminum alloy physical properties:

| Density | 2.68g/cm³ |

| Melting point | 608-650℃ |

| Thermal conductivity | 130-160W/(m·K) |

| Linear expansion coefficient | 23.1×10^-6/℃ |

| Resistivity | 0.049Ω·mm²/m |

Marine grade 5454 aluminum sheet application areas:

1. Marine facilities: 5454 aluminum sheets are widely used in the production of pipes, brackets, frames and other components in marine facilities, and can withstand the impact of natural forces such as wind, waves, tides and other natural forces in the marine environment.

2. Shipbuilding: 5454 aluminum sheets are also commonly used in the manufacture of hull structures, decks, cabin partitions and other components. They have good sealing and seawater corrosion resistance, ensuring the safety and durability of ships.

Contact Us