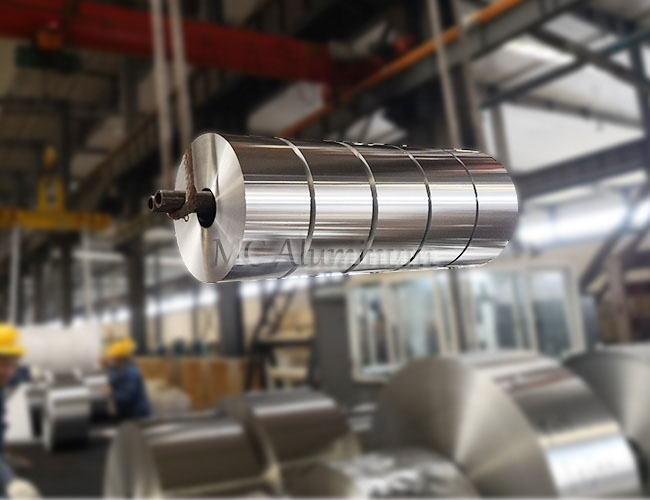

8000 series aluminum foil for pharmaceutical packaging

Nowadays, aluminum foil materials made of 8000 series aluminum alloys are specially used for pharmaceutical packaging. This type of aluminum foil is widely used in the packaging field of medicines due to its excellent performance, especially in blister packaging (also known as aluminum-plastic blisters), sealed packaging, and other pharmaceutical packaging applications that require high protection. The commonly used alloys for aluminum foil for pharmaceutical packaging mainly include 8011 and 8021, and 8079 is used in a small amount. The thickness is generally between 0.02mm and 0.03mm, and H18 and O states are usually used. The product surface has no defects such as black spots, pinholes, and oxidation;

Introduction to 8 series aluminum foil alloys for pharmaceutical packaging:

8011 alloy: The main element is aluminum (Al), supplemented by a small amount of iron (Fe) and silicon (Si). The addition of iron and silicon improves the strength and forming properties of aluminum foil. It has advantages such as good formability, tensile strength and barrier properties. It is widely used in blister packaging, inner layer of composite packaging materials, etc.

8021 aluminum alloy: The aluminum purity is high, and the proportion of iron and silicon is increased, making it more tear-resistant and mechanically strong. It has the advantages of high barrier properties, ductility and softness. It is widely used in blister packaging, liquid, powder and other medicine packaging.

8079 aluminum alloy: It contains a high amount of iron and silicon, and is an aluminum foil with high strength, good elongation and compressive strength. It is suitable for subsequent processing such as coating, lamination, and printing. It is widely used in the packaging of special medicines, blister packaging, etc.

Features of 8 series aluminum foil for medical packaging:

1. Excellent barrier properties: It has excellent barrier effects on light, moisture, oxygen, etc., and can effectively protect the stability of medicines and extend the shelf life of medicines.

2. High strength and flexibility: The alloy composition of 8000 series aluminum foil gives it good mechanical properties and is not easy to break during stamping and processing.

3. Corrosion resistance and chemical stability: It has high tolerance to common chemicals and pharmaceutical ingredients, and is not easy to react with medicines.

4. Environmental protection and recyclability: Aluminum foil is a recyclable material and meets the environmental protection requirements of modern pharmaceutical packaging.

5. Printability and heat sealing performance: A variety of patterns can be printed, which is convenient for brand identification; and it is easy to compound or heat seal with other packaging materials such as PVC and PP.

Surface quality requirements of 8 series aluminum alloy for pharmaceutical packaging:

1. The surface should be clean and flat, without obvious scratches, dents, oxidation spots or corrosion marks.

2. The surface flatness shall not exceed 0.005mm, and the surface finish shall not be less than Ra 0.6.

3. The height difference of the concave and convex surface of the aluminum foil shall not exceed 0.01mm, and the concave area shall not exceed 10% of the total surface area.

4. The number of pinholes on the surface of the aluminum foil should be as small as possible. In any square meter, no pinhole with a diameter of 0.3mm is allowed, and no more than 5 pinholes with a diameter of 0.1~0.3mm are allowed.

MC Aluminum is a manufacturer of aluminum foil raw materials for pharmaceutical packaging. The company's 8011-H18 aluminum foil, 8021 aluminum foil, and 8079 aluminum foil have the advantages of high cupping value, high heat sealing strength, no pinholes, and good sealing. It is a supplier of aluminum foil raw materials for pharmaceutical packaging for various domestic and foreign pharmaceutical packaging companies.

Contact Us