8011 aluminum foil for hot-rolled pharmaceutical bottle cap material

Aluminum caps are often used in some medicine and wine packaging. It is an important part of the supporting use of bottle packaging containers. Its main function is to prevent the contents of the bottle from overflowing and prevent foreign objects from entering the bottle.

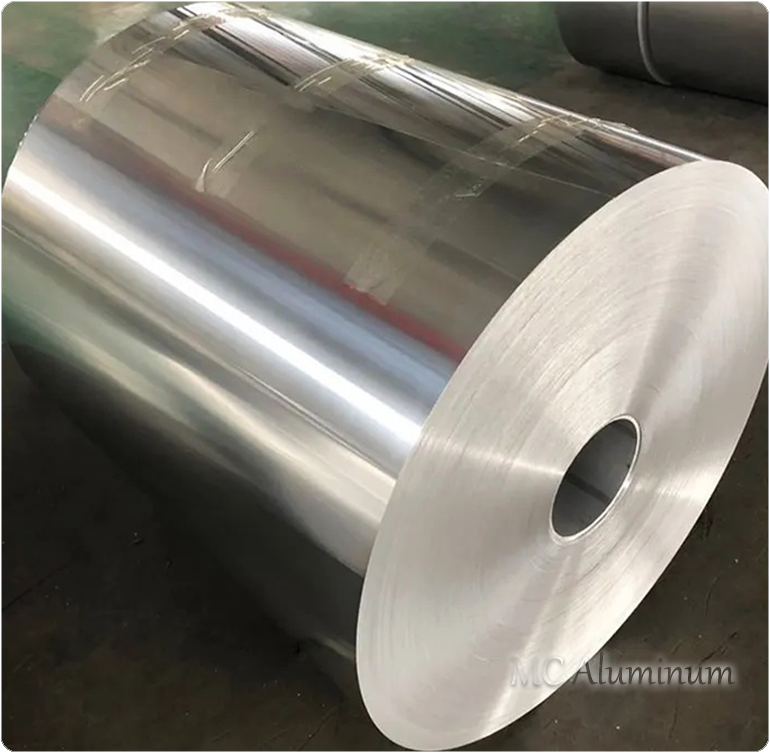

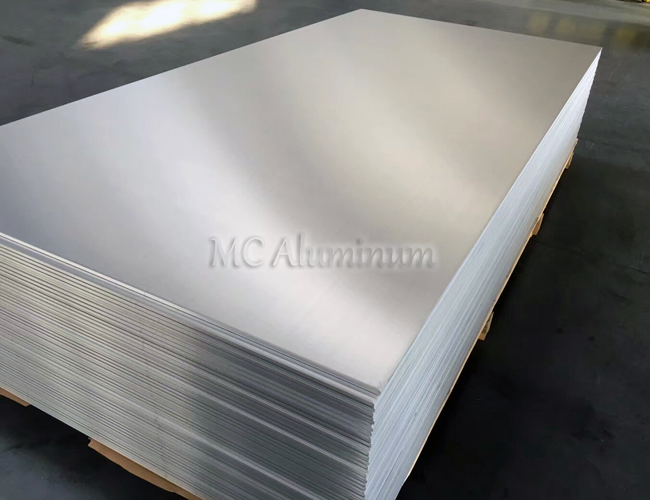

Aluminum bottle cap raw materials generally use 8011 aluminum foil, 3003 aluminum coil, 3105 aluminum coil, etc., which are mostly processed on a production line with a high degree of automation. The requirements for the strength, elongation, and dimensional deviation of the material are very strict, otherwise it will Breaks or creases occur during processing.

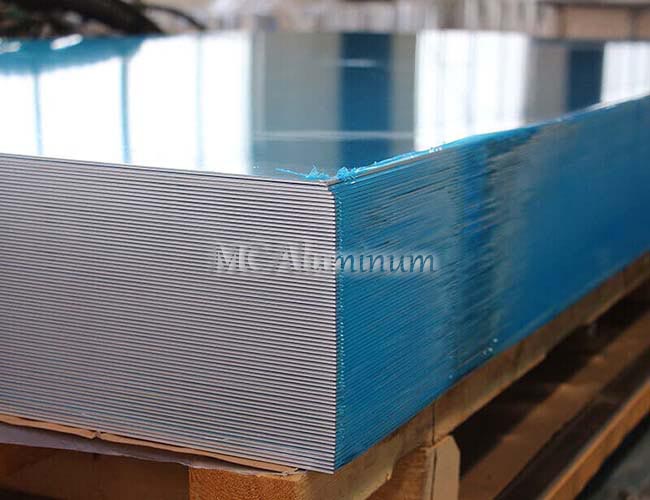

The medical aluminum bottle cap is made of 8011 hot-rolled aluminum foil, with a general thickness of 0.20mm-0.23mm and a width of 449mm-796mm. The product has good internal uniformity, good stamping formability, and stable performance. The aluminum cap made of it has a simple structure and good sealing performance. The utility model has the advantages of convenient opening, low cost, and simple and convenient use. Compared with plastic bottle caps, aluminum bottle caps not only have better performance, but also are pollution-free and can be recycled.

The requirements for aluminum bottle caps are relatively high. The surface of the aluminum foil produced by MC Aluminum is smooth and clean, without rolling marks, scratches and stains, which can meet the requirements of customers.

MC Aluminum specializes in the production of aluminum foil for more than 20 years. It selects high-quality raw materials, introduces advanced production equipment, and strictly controls the production process of 8011 aluminum foil. The source of aluminum foil raw materials for the aluminum bottle cap factory, welcome new and old customers to come to order!

Contact Us