Advantages of aluminum sheet for mold

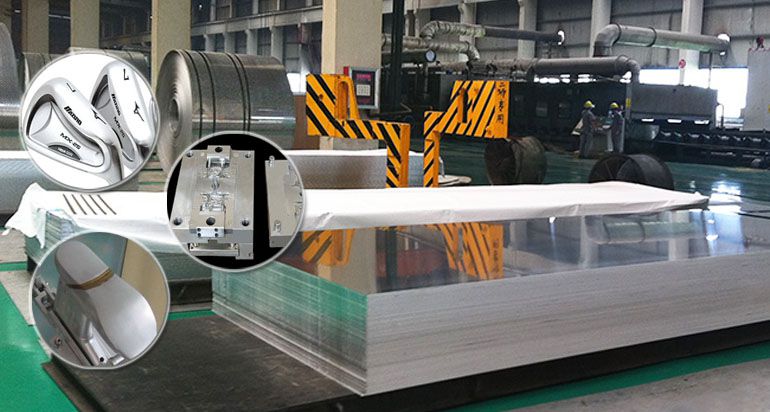

The aluminum plates for molds mainly use 5-6 series alloys with medium hardness and 2-7 series alloys with high hardness. For example, the commonly used 6061-t6 aluminum plate, 6082 aluminum plate, 5052 and 7075 aluminum alloy and so on. In fact, aluminum plate has the characteristics of high precision, long service life, easy processing, and can be recycled many times. Therefore, it is widely used in mold manufacturing, such as hardware tool molds, car door molds, shoe molds, underwear molds, kettle molds, precision instrument molds, etc.

Commonly used alloy series

6000 series die aluminum plate is the most commonly used aluminum formwork. Including 6061, 6063, 6082, 6005 aluminum alloys, etc. The common tempering states are T6, T651 and so on. These aluminum plates for molds have high mechanical properties, such as high strength, machinability, punchability, toughness, weldability, corrosion resistance, etc. This is due to the addition of Si as the main alloy in the 6000 series alloys, with the exception of Mg and Al.

7000 series aluminum template belongs to aluminum-zinc-magnesium alloy. Common ones are 7075-t6 aluminum, 7075-t651, 7005, 7A09 alloy, etc. For example, aluminum plate for 7075 mold has compact structure, good mechanical properties and good anode reaction. In addition, its fine grains provide better performance in deep drilling and improve tool wear resistance. Therefore, it is widely used in blow molding (bottle) molds, ultrasonic plastic welding molds, golf heads, shoe molds, paper plastic molds, foam molding molds, wax molds, mold processing, fixtures, etc.

Advantages of aluminum plate for mold

1. High strength heat treatable alloy.

2. Good mechanical properties.

3. Easy processing and good wear resistance.

4. Good corrosion resistance and oxidation resistance.

Contact Us