Aluminum Plate for Ship Structural Parts

What are ship structural parts?

Ship structural parts refer to the various parts and components that make up the hull, mainly including the bottom plate, side plate, deck, bulkhead and other parts. These parts are tightly connected by welding, riveting and other methods to form a solid hull. Ship structural parts play a vital role in ship construction and operation.

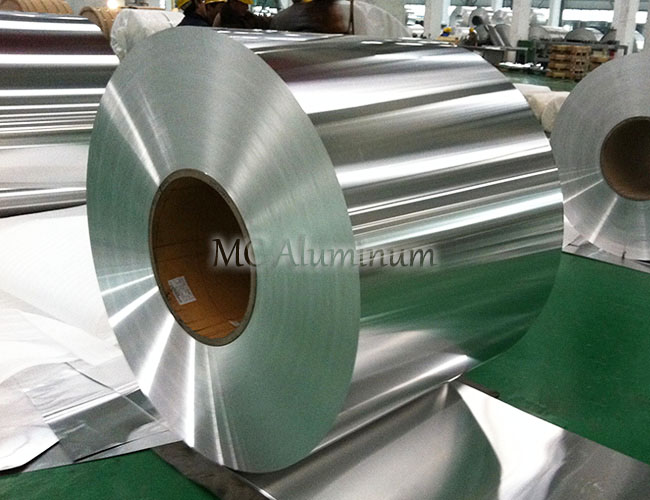

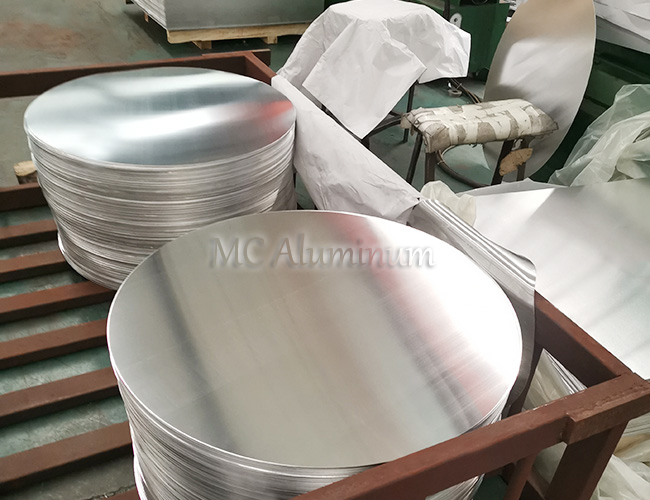

Aluminum plate for ship structural parts is an aluminum alloy material designed for ship manufacturing and repair. It has the characteristics of light weight, high strength and corrosion resistance. It is widely used in key parts such as hulls, decks, bulkheads, etc. of ships. MC Aluminum's 5xxx and 6xxx marine aluminum plates all need to pass relevant classification society certification (such as ABS, DNV GL, LR, CCS, etc.) to ensure that their performance meets the standards of marine engineering.

Marine aluminum plates generally use aluminum-magnesium alloys and aluminum-magnesium-silicon alloys, and the main grades include:

5000 series (such as 5083, 5052, 5454, 5754)

With magnesium as the main alloying element, it has excellent corrosion resistance and welding performance.

5083 is the main choice of aluminum plates for ships, especially suitable for use in seawater environments. It is often used in the deck, engine pedestal, ship side, bottom outer plate and other parts of the ship. These parts need to bear large loads and stresses, and the high strength and good weldability of 5083 aluminum plates can meet these requirements.

6000 series (such as 6061, 6082)

With magnesium and silicon as the main alloying elements, it has high strength and good corrosion resistance and weldability.

Commonly used in structural parts with high strength requirements, such as deck frames.

Features of marine-grade aluminum plates for ship structures:

1. Lightweight: The density of aluminum alloy is about 1/3 of that of steel, which can significantly reduce the weight of the ship and improve the speed and fuel efficiency.

2. Corrosion resistance: Especially in the marine environment, aluminum plates show excellent corrosion resistance and long service life.

3. Good machinability: Aluminum alloys are easy to process into complex shapes and are suitable for welding processes.

4. High strength: By reasonably selecting alloys and heat treatment, higher strength can be achieved to meet the structural requirements of ships.

5. High safety: Aluminum alloys do not burn, are safe in case of fire, and meet the safety requirements of shipbuilding.

6. Environmental protection: Aluminum alloys have a high recycling rate and can be recycled and reused, meeting environmental protection requirements.

7. Economic efficiency: On the premise of meeting the above requirements, the economy of aluminum plates should also be considered to reduce the manufacturing cost of ships.

Production process requirements:

Strict surface quality: The surface of the aluminum plate needs to be smooth and free of defects such as cracks and pores to ensure anti-corrosion performance.

High dimensional accuracy: Ensure good fit during installation.

Excellent welding performance: Ensure welding strength and crack resistance during shipbuilding

Contact Us