Aluminum sheet for furniture industry

Aluminum has many advantages, and its application in the home furnishing industry is becoming more and more common. At this stage, the application of all-aluminum furniture is very wide, involving civil furniture, education, office and sports medical. All-aluminum furniture has the advantages of corrosion resistance, moisture resistance, no deformation, light weight and environmental protection. It conforms to the trend of environmental protection and is a "potential stock" in the furniture market.

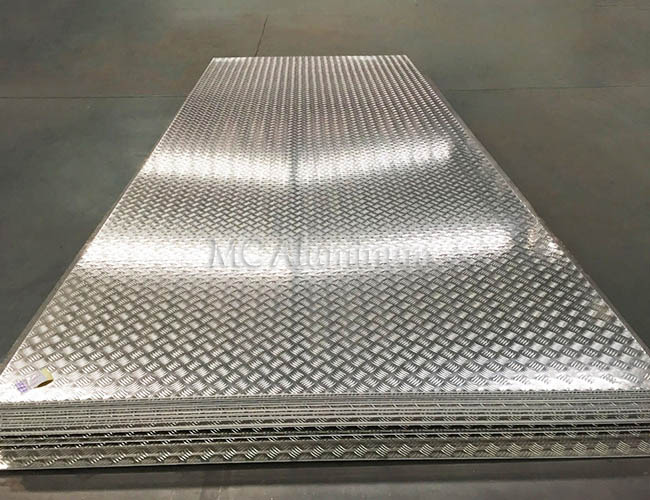

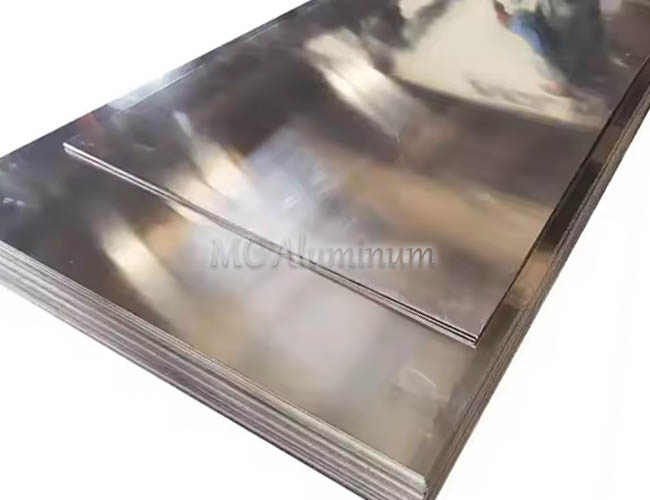

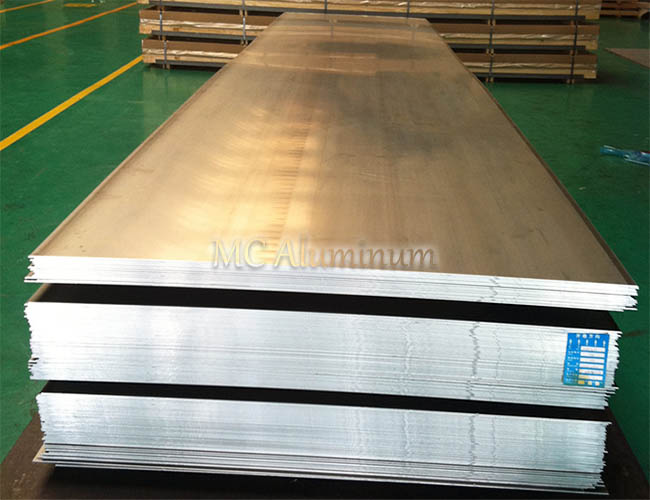

Judging from the appearance of the products of the current all-aluminum furniture manufacturers, most of them use wood-grain aluminum honeycomb panels, which are composed of two layers of aluminum panels and an aluminum honeycomb core in the middle. The outer aluminum plate is made of 1100 aluminum plate, 3003 aluminum plate, etc., with wood grain transfer printing on the surface, imitating the appearance of traditional wooden furniture. It is not only light in weight, environmentally friendly, but also durable. The inner aluminum honeycomb core is bonded and laminated by multiple layers of aluminum foil, and then stretched to form a regular regular hexagonal honeycomb core, which has the advantages of not easy to deform and good sound insulation effect.

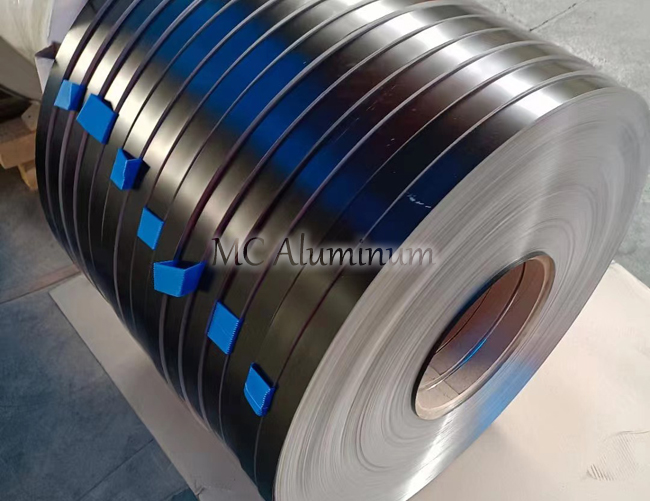

MC Aluminum supplies the aluminum plate material for the upper and lower panels of the aluminum honeycomb plate, and the aluminum foil material for the aluminum honeycomb core, which can be customized according to user needs.

Aluminum honeycomb panels are widely used in homes and have the following advantages:

1. Not easily deformed: the core of the honeycomb aluminum plate is a hexagonal aluminum honeycomb core, the structure is light and stable, and will not cause structural deformation.

2. Good sound insulation effect: the honeycomb core structure divides the interlayer into many closed cells, so that part of the sound wave can be absorbed and converted into heat energy and consumed, so it has a good sound insulation effect.

3. Fireproof and moisture-proof: the face plate, back plate and core layer of the honeycomb aluminum plate are all made of aluminum alloy, which is a flame-retardant material. In addition, the aluminum alloy itself has good chemical stability and is durable

Corrosion and moisture resistance.

4. Energy saving and environmental protection: aluminum has high recyclable value.

MC Aluminum specializes in the production of aluminum sheet strip foil, 1100 aluminum sheet, 3003 aluminum sheet, 5052 aluminum sheet for aluminum honeycomb panels, 3003 aluminum foil, 3004 aluminum foil for aluminum honeycomb core, etc., providing a variety of specifications to meet the diverse customization needs of users. Manufacturers Direct supply, price concessions.

Contact Us