Aluminum Strip for New Type Capacitor Shell

As one of the more commonly used electronic components, capacitors are mainly used to store electricity and energy. The capacitor shell is set up to protect the internal components, which has a great influence on the service life of the capacitor. Common capacitor shell materials are iron, plastic, and aluminum alloy. Aluminum alloy has the advantages of easy heat dissipation and corrosion resistance, and can also eliminate the risk of possible leakage at the pressure groove. From a comprehensive comparison, the aluminum shell is a good choice.

The capacitor casing is mainly stamped from 99% pure aluminum plate, such as 1100 aluminum strip, which has the characteristics of good processing performance, low ear forming rate, high forming rate, small surface grains, fine and smooth surface after deep drawing, etc. It can fully meet the requirements of the current market for the use of high-precision capacitor shells.

Performance advantages of 1100 aluminum strips for capacitor shells:

1. Good corrosion resistance and long service life;

2. Excellent formability, strong and durable;

3. Good weldability and good sealing;

4. Good heat transfer and fast heat dissipation.

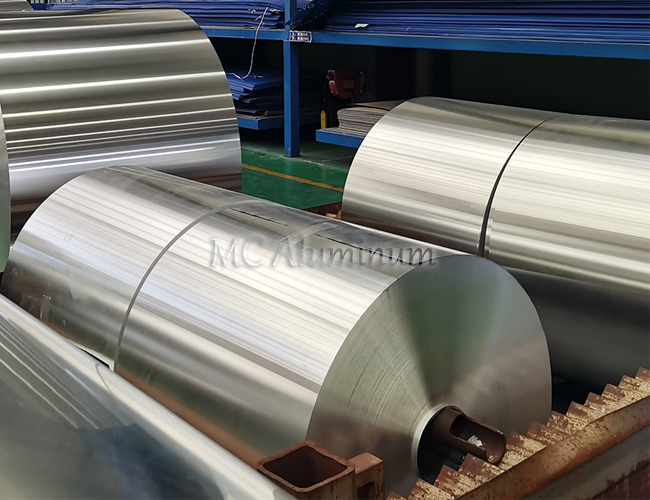

MC Aluminum is a manufacturer of aluminum plates. The aluminum strips used for capacitor shells produced by MC Aluminum have high precision, small anisotropy, low ear-making rate, high forming rate, and meet high requirements for use. MC Aluminum specializes in the production of 1100 aluminum plates. The product has flat shape, clean surface, no black spots, black silk, etc., can be customized according to customer needs, large output, fast delivery, global export, and guaranteed after-sales service.

Contact Us