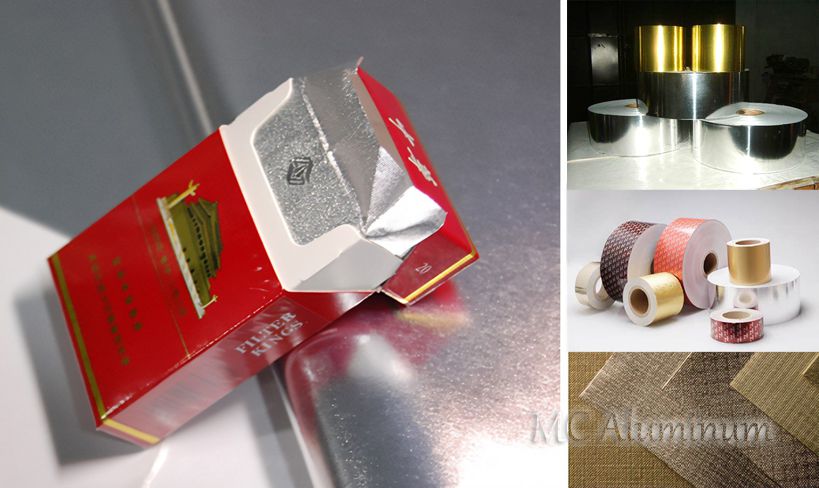

Cigarette Aluminum Foil

Cigarette aluminum foil is a thin sheet of aluminum used to wrap cigarette packages to protect cigarettes from moisture and oxidation, making them easier to transport and store. The thinness and tightness of the packaging prolongs the shelf life of the product and maintains the freshness, quality and taste of cigarettes. In addition, aluminum foil helps protect cigarettes from external elements.

Cigarette aluminum foil is usually made of 8011 or 1235 grade aluminum alloy, which consists of 1060-O, 1100-H14 and 8011-H14 type alloys. It has a thickness of 0.0065 mm and a width of 90 mm, and is usually silver in color. The surface of the aluminum can be coated with colorful printed patterns to make the product look stylish and beautiful. Although both 8011 and 1235 grade aluminum are used, the 8011 grade is a more popular choice because it is more versatile in packaging.

Aluminum foil for cigarette packaging has many performance advantages:

1. Strong and durable

2. Good formability

3. Excellent sealing to prevent air, moisture and light from entering the packaging

4. High and low temperature resistance

5. Non-toxic and tasteless, safe and hygienic

6. Aluminum foil can be printed with various patterns and texts, and has a beautiful appearance

Appearance quality of aluminum foil for cigarettes:

1. The cross section of the aluminum foil is neat, without burrs, clamped edges, ruffles, cracked edges, tower shapes, loose rolls, bars, bumps and other defects.

2. The brightness of the aluminum foil should meet the standards and should not be oxidized or discolored.

3. The size and number of roller prints and holes should meet the requirements of relevant standards to ensure the beauty and practicality of the aluminum foil.

4. The surface of the aluminum foil can be coated with a color printed pattern, but the printing quality should be clear and firm, and not easy to fall off or fade.

Cigarette aluminum foil provides many advantages to enterprises and consumers and is the first choice for cigarette, chocolate and candy packaging. It is more affordable than traditional materials and safer and more hygienic than plastic and other alternative materials. The product is thin and compact, easy to store and transport, and its excellent thermal insulation properties help keep food hot or cold for a long time. The product is also non-toxic and will not release harmful substances or odors into the environment.

Contact Us