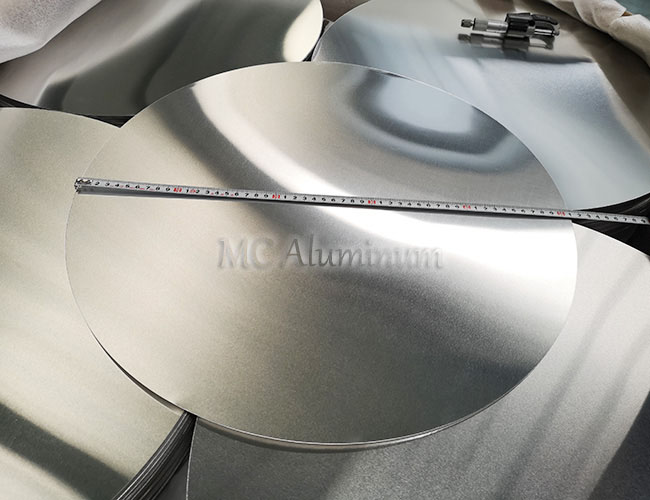

Hot rolled aluminum circle

Hot-rolled aluminum disc is to add various alloying elements (main alloying elements are copper, silicon, magnesium, zinc, manganese, secondary alloying elements are nickel, iron, titanium, chromium, lithium, etc.) Mechanical properties and chemical indicators of aluminum plates. Hot-rolled aluminum discs have some special properties that pure aluminum sheets do not have, and are widely used in special environments, such as ships, refrigerators, molds, aerospace equipment, etc.

The raw materials of hot-rolled aluminum discs generally choose 1 series, 3 series, 5 series, and 8 series as the main raw material alloys. 1060 aluminum circles, 1070 aluminum circles, 3003 aluminum circles, etc. are deeply loved by cooker manufacturers.

Hot rolled aluminum circle

Hot-rolled aluminum disc is to add various alloying elements (main alloying elements are copper, silicon, magnesium, zinc, manganese, secondary alloying elements are nickel, iron, titanium, chromium, lithium, etc.) Mechanical properties and chemical indicators of aluminum plates. Hot-rolled aluminum discs have some special properties that pure aluminum sheets do not have, and are widely used in special environments, such as ships, refrigerators, molds, aerospace equipment, etc.

The raw materials of hot-rolled aluminum discs generally choose 1 series, 3 series, 5 series, and 8 series as the main raw material alloys. 1060 aluminum discs, 1070 aluminum discs, 3003 aluminum discs, etc. are deeply loved by cooker manufacturers.

Common annealing process for hot-rolled aluminum wafers:

1) Complete annealing: heating at 390-430 °C; depending on the effective thickness of the material, the holding time is 30-120 minutes; cooling with the furnace at a speed of 30-50 °C/h to 300 °C, and then air cooling.

2) Rapid annealing: heating at 350-370°C; depending on the effective thickness of the material, the holding time is 30-120min; air or water cooling.

3) Quenching and aging: quenching at 500-510°C, air cooling; artificial aging at 95-105°C, 3h, air-cooling; natural aging at room temperature for 120h

Application of hot-rolled aluminum disc

1. Use of kitchen utensils

Due to its light material and corrosion resistance, hot-rolled aluminum discs are often used to make non-stick pans, pressure cookers, aluminum plates for kitchen utensils, cookware, etc. The specially treated oxide film on the surface has a suitable thickness and stable performance, and can be recycled reliably. At the same time, the stylish and atmospheric appearance of the hot-rolled aluminum disc perfectly coordinates with the modern kitchen style, looking simple and exquisite.

2. Use of hardware products

Many common hardware products in life are made of hot-rolled aluminum discs, such as lampshades, lamps, water heater shells, glass window locks, and some capacitor aluminum shell blanks. Because of its excellent corrosion resistance and malleability, it can be made into the required shape according to the demand, meeting the design requirements of many lamps and lampshades. At the same time, the hot-rolled aluminum disc after secondary processing can be made into various electrical casings, especially suitable for the hardware industry.

3. Household appliances

Household appliances are indispensable daily necessities for every household. They not only need to be beautiful and durable, but also need to have high reliability. The easy-to-use hot-rolled aluminum disc has excellent thermal conductivity, heat dissipation, weather resistance and corrosion resistance. It is often used to make heat-conducting chassis of electric kettles, inner pots of rice cookers and various heat-conducting components, making household appliances more high-end and elegant. Reliable and worry-free.

The popularity of hot-rolled aluminum wafers is not only reflected in the above aspects, but also in unexpected places in life, ranging from medicine, electronics, daily chemicals, culture and education and auto parts. Sellers in the market can provide all kinds of products. Consumers need to think rationally and choose hot-rolled aluminum wafer manufacturers with good sales in the industry to get twice the result with half the effort.

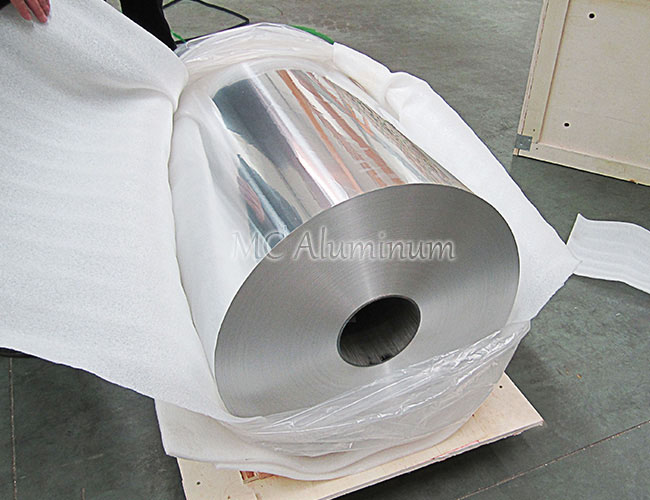

MC Aluminum specializes in the production of hot-rolled aluminum circles, which can be customized to produce 1 series, 3 series, 5 series, and 8 series aluminum circles. The product models are complete, the output is large, and the delivery is fast. It is widely favored by the market and is often exported to foreign.

Contact Us