Lightweight battery tray, choose aluminum or steel

The automobile industry is developing rapidly, but the energy problem is becoming more and more urgent, and the environmental problems caused by automobiles are also attracting attention. Developing the new energy automobile industry is an effective way to alleviate the energy crisis, reduce greenhouse gas emissions, and reduce environmental pollution. At present, new energy automobiles have become an important direction for the transformation of the automobile industry.

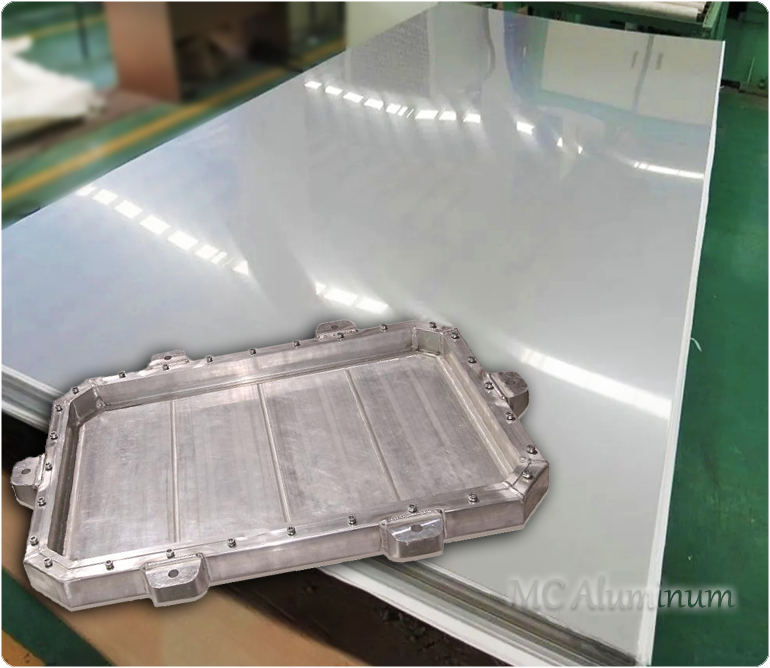

The battery module is the core component of new energy vehicles, and the battery tray serves as the support of the entire battery module, and its structural strength and sealing are related to the safety of the battery. The tray occupies 20%~30% of the battery weight. Under the premise of ensuring the functional safety of the battery, the lightweight of the tray has become one of the main improvement goals of the battery structural parts. The battery tray is usually made of aluminum alloy and steel. From the perspective of material integration, aluminum alloy material can firstly meet the structural requirements of vehicle components including the battery system, and is still the preferred material to replace some steel structures.

The battery aluminum tray is mainly made of 6061 aluminum sheet, which requires high mechanical properties such as weldability and processability of the material. Good plasticity and excellent corrosion resistance, especially no stress corrosion cracking tendency, good welding performance, making the 6-series aluminum profiles very suitable for the application of this project.

The 6061 aluminum plate is an Al-Mg-Si alloy, which belongs to a heat-treatable alloy that can be strengthened. It has good plasticity and corrosion resistance, good welding performance, and excellent machinability, which meets the requirements for the use of battery aluminum trays. In addition, the density of the aluminum alloy material is only 1/3 of the steel material, and its weight reduction and energy saving effects are obvious. At the same time, aluminum alloy materials are easier to recycle. The comprehensive cost-effective advantages of aluminum determine that it becomes the preferred material for automotive lightweight applications.

The proportion of aluminum in the application of global vehicle products is increasing year by year. The main reason for the application of aluminum as a lightweight feature is that it conforms to and conforms to the development trend of energy saving, environmental protection, and lightweight products.

MC Aluminum is a manufacturer of lightweight automotive aluminum sheets. The company's production of automotive aluminum sheets includes 6061 aluminum sheets, 5083 aluminum sheets, 5052 aluminum sheets, 3003 aluminum sheets, 3105 aluminum sheets, etc. , exported to many countries and regions overseas, providing aluminum raw materials for automobile manufacturers, with favorable prices and perfect after-sales service, users can rest assured to order.

Contact Us