Radiator 1100 aluminum strip

In the field of modern radiator manufacturing, material selection is a key factor related to performance and quality, and 1100 aluminum strip is becoming the favorite choice of many radiator manufacturers due to its excellent performance characteristics, in terms of efficient heat dissipation and It plays an indispensable role in stable operation.

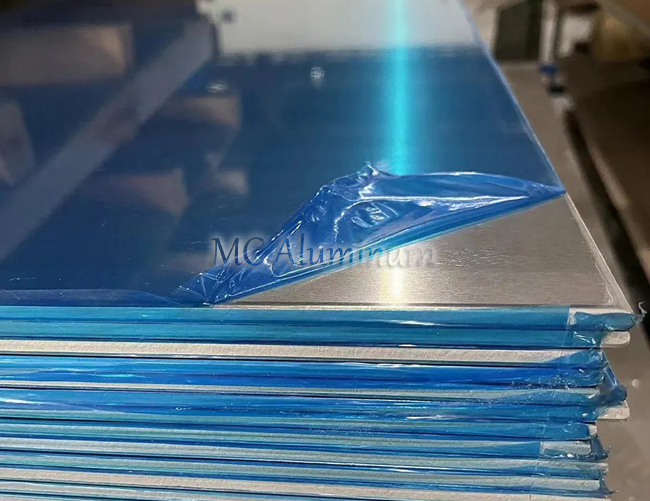

1100 aluminum strip is a pure aluminum strip (aluminum content is generally above 99%). It has excellent thermal conductivity, corrosion resistance and formability, so it is often used to manufacture components such as radiators that require high thermal conductivity.

In radiators, 1100 aluminum strip has the following advantages over other materials:

1. Light weight

The low density of aluminum can significantly reduce the weight of radiators and is suitable for areas with high weight requirements, such as automotive and aerospace, to improve fuel efficiency and flight performance.

2. Low cost

The raw material and processing costs are low, suitable for mass production, which can reduce the selling price of radiators and improve market competitiveness.

3. Good thermal conductivity

Good thermal conductivity quickly transfers and dissipates heat, improves heat dissipation efficiency and extends the service life of the equipment.

4. Strong corrosion resistance

The oxide film formed on the aluminum surface can effectively prevent corrosion, maintain the performance and appearance of the radiator, and reduce maintenance costs.

5. Excellent processing performance

Radiator components of different shapes and sizes can be easily manufactured through a variety of processing techniques, providing design and manufacturing flexibility.

6. High recyclability

Aluminum recycling has low energy consumption and small performance loss, contributes to resource conservation and environmental protection, and meets the requirements of sustainable development.

Processing technology of 1100 aluminum strip for radiator:

Rolling: Aluminum ingots are hot-rolled or cold-rolled into aluminum strips of different thicknesses. 1100 aluminum strips for radiators usually use a cold-rolling process to obtain more precise dimensions and better surface quality.

Slitting: According to the specific size requirements of the radiator, the wide aluminum strip is longitudinally slit into narrow strips of different widths by a slitting machine, which is used to manufacture fins or other components of the radiator.

Stamping/drawing: Use molds to stamp or stretch aluminum strips to form radiator components of various shapes, such as fins, heat pipes, etc., to increase the heat dissipation area and improve the heat dissipation effect.

Welding: Connect different aluminum strip components together through a welding process to form a complete radiator structure, ensuring welding quality and sealing to ensure the normal operation of the radiator.

Surface treatment: In order to improve the corrosion resistance, wear resistance and decorative properties of aluminum strips, surface treatments are usually carried out, such as anodizing, electrophoretic coating, powder spraying, etc. Among them, anodizing treatment can form a hard layer on the surface of the aluminum strip. , wear-resistant and corrosion-resistant oxide film, which can not only extend the service life of the radiator, but also obtain various colors through electrolytic coloring or dyeing processes.

MC Aluminum provides various materials such as 1060, 1100, 3003, 5052, 6061, 6063 and other aluminum plates, aluminum coils, and aluminum strips, which are suitable for heat dissipation. Generally, the radiator aluminum plate uses 1060 aluminum plate (pure aluminum plate). The higher the aluminum content, the better the heat dissipation and thermal conductivity. There are certain requirements for strength. For example, products that require tapping can use 3003 aluminum plate, 5052 aluminum plate, and 6061 aluminum plate series. The alloy aluminum plate is used as the aluminum plate material for heat dissipation.

Contact Us