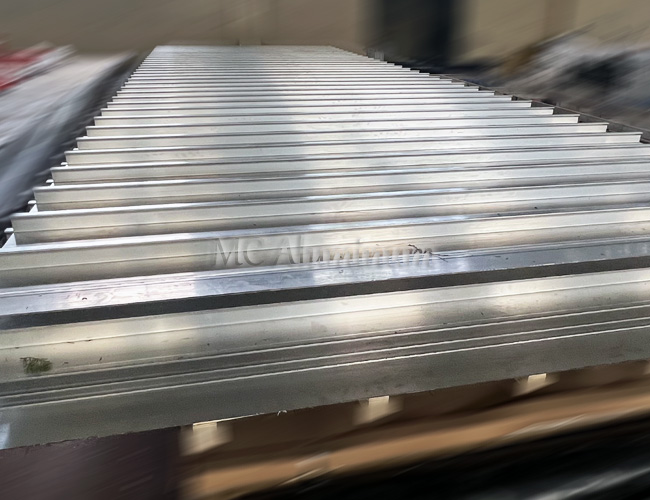

Roller coated aluminum coil customization

Roller coating refers to the continuous and uninterrupted degreasing, chemical pretreatment and color coating of the aluminum substrate. After roller coating, it becomes a roll of aluminum plate with a paint layer. Products include fluorocarbon-coated roller-coated aluminum sheets/rolls (PVDF) and polyester-coated roller-coated aluminum sheets/rolls (PF). Commonly used are 1100, 3003, 3004, 3005, 3105, 5182, 5002, 5005 and other aluminum alloy substrates, with coating thickness of 0.07mm-2.0mm; and can be processed by lamination, striping, embossing, etc.

Color-coated aluminum coils can also be single-coated (4μm-20μm), double-coated (25μm-28μm), or triple-coated (35μm-38μm). The surface patterns are diverse and are also called wood grain aluminum coils and stone grain aluminum coils. Brick pattern, camouflage aluminum coil, fabric aluminum coil, etc. The pattern can also be customized. Because of their different uses, they are often called roofing materials (aluminum-magnesium-manganese roofing systems), ceiling materials (for aluminum alloy ceilings), brushed sheets (surfaces with brushed treatment), etc.

Color-coated aluminum coils should have good weather resistance. The paint pattern formed by joint coating and high-temperature baking has high gloss retention, good color stability, rich colors, and can meet various color requirements of modern architecture with small color difference changes. Polyester paint has a 10-year warranty, and fluorocarbon paint has a 20-year or more warranty.

Common specifications and models of roll-coated aluminum coils:

| Alloy | A1100, A3003, A3004, A3105, A5052, A8011……. |

| Coating | luorocarbon, polyester, epoxy |

| Thickness | 0.2mm-4.00mm |

| Processing width | Coated aluminum coil 20mm-1500mm |

| Coated aluminum sheet 800-1750mm | |

| Barrel core diameter | 150mm, 405mm, 505mm, 508mm, 510mm |

| Coating thickness | PVDF (fluorocarbon) ≥ micron |

| POLYESTER(polyester)≥18micron | |

| Glossiness | 10-90% |

| Coating hardness | >2H |

| Adhesion | no less than grade 1 |

| Color | Color can be adjusted according to RAL and Pantone international color cards or customer samples |

What are the advantages of roll-coated aluminum coils?

1. Exquisite appearance, rich texture, realistic effect and clear texture.

2. Fire resistance: Corrosion resistance, moisture resistance, hardness and strength are all compared with the solid wood floating method.

3. Rust, damage and UV protection.

4. Long service life, no discoloration or deformation for 10-15 years.

5. Roller-coated aluminum coils have strong plasticity and can be processed into various complex shapes. Its back can be filled with materials such as thermal insulation, sound insulation, and sound absorption to make it more functional.

6. Protect the environment, protect the ecological environment, and reduce the waste of material resources.

Contact Us