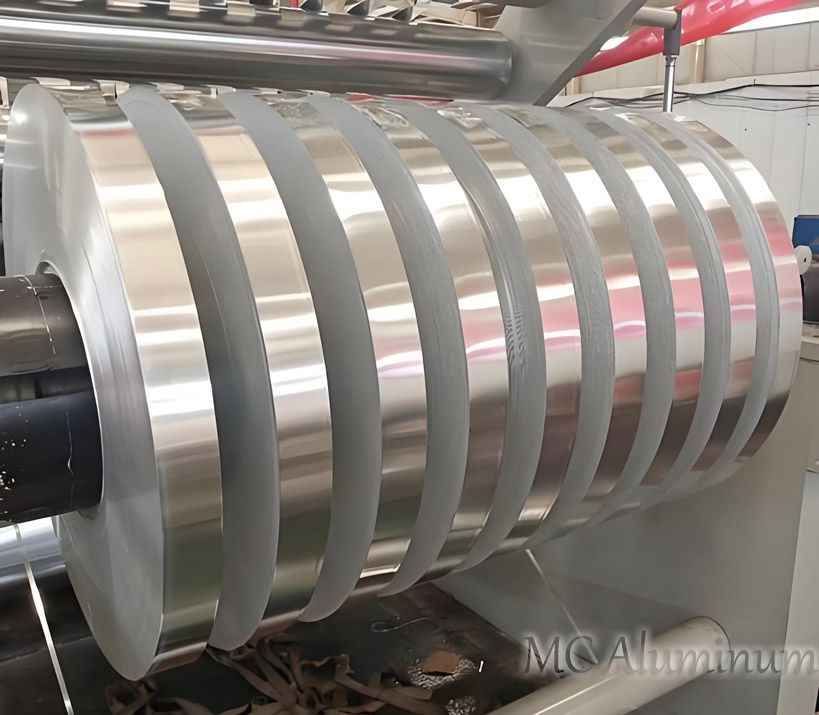

Stamped aluminum strip

What is stamped aluminum strip?

Stamped aluminum strip is made of pure aluminum or aluminum alloy cast aluminum coil, hot-rolled aluminum coil as raw material, first rolled into thin aluminum coils of different thicknesses and widths by cold rolling mill, and then longitudinally cut into aluminum strips of different widths by slitting machine according to specific uses. This kind of aluminum strip is widely used in various stamping processing scenarios due to its good physical and chemical properties, such as light weight, high strength, good thermal conductivity and electrical conductivity, strong corrosion resistance, etc.

Common aluminum alloy materials for stamped aluminum strips include 1050, 1060, 1100, 3003, 5052, etc. These materials have different mechanical properties and application characteristics. The thickness ranges from 0.1mm to 5mm, and the width can be customized according to customer needs. Stamped aluminum strips are widely used in industrial manufacturing, electronic equipment, automobiles, aviation, construction and other industries.

Stamping process:

Stamping is a pressure processing method. The processing technology of stamped aluminum strip mainly includes aluminum material preparation, stamping forming, cleaning, finishing, inspection and packaging. Among them, stamping forming is the key step. It is necessary to use stamping machinery to apply pressure to the aluminum strip to make it plastically deformed, so that the mold can cut, punch, bend, stretch and other forming operations on the aluminum strip to form the required shape and size.

Characteristics of stamped aluminum strip:

1. Good stamping performance: It has good plasticity and ductility and can smoothly form the required shape.

2. Lightweight and high strength: Aluminum alloy has low density, light weight and high strength, which is suitable for fields with lightweight requirements.

3. Excellent electrical and thermal conductivity: It is suitable for manufacturing parts that need heat dissipation or conduction.

4. Strong corrosion resistance: After special treatment, it can be used for a long time in harsh environments.

5. Good stability: It has chemical and thermal stability and can maintain performance under high temperature and extreme conditions.

6. Green and environmentally friendly: Aluminum is recyclable, which helps reduce energy consumption and carbon emissions.

MC Aluminum can provide aluminum strips of various series and materials, with the thinnest being 0.1mm and the thickest being 3mm, with smooth edges and no burrs, and no scratches on the surface. The product quality is stable, with a small amount of inventory, and exported to many countries overseas, with fast delivery and guaranteed after-sales service.

Contact Us