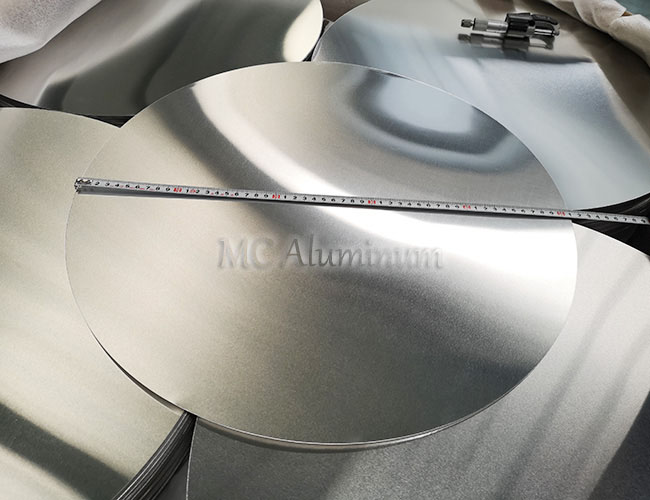

The raw material of the cake tray is 3004 aluminum alloy

With the development of society and the improvement of people's awareness of environmental protection, aluminum, as an energy-saving resource, has a very wide range of applications in life. The aluminum dinner plates, aluminum pots, cake trays, etc. we use can all be made of specific aluminum alloys. Due to the good corrosion resistance, ductility and processability of aluminum materials, aluminum products are loved by the public.

People's daily baking pan materials are roughly divided into three types: aluminum alloy, aluminized steel plate, stainless steel, etc. Choosing a good baking pan will have a multiplier effect on baking. Aluminum alloy is often used for cake trays.

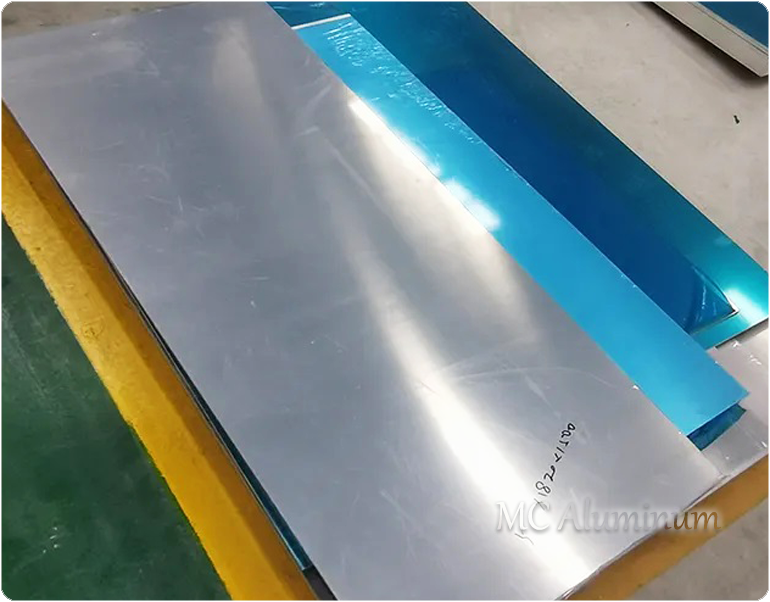

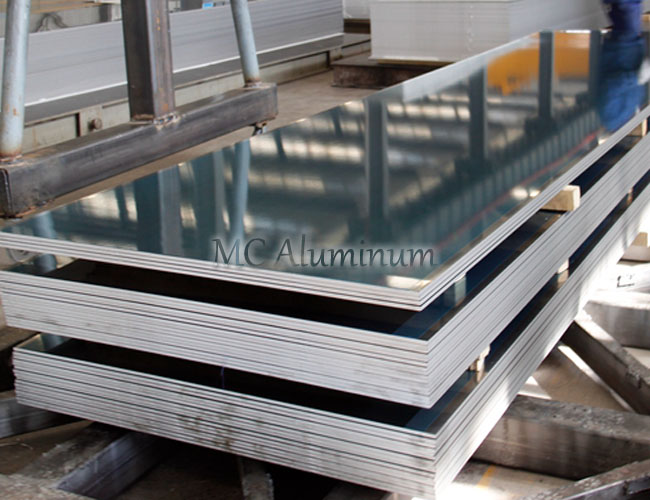

The 3004 series aluminum plate belongs to a series of aluminum-manganese alloys. It has higher strength than 3003, excellent formability and good corrosion resistance. The strength of this alloy is not high (slightly higher than industrial pure aluminum), and it cannot be strengthened by heat treatment. Improve its mechanical properties: it has high plasticity in the annealed state. The cake tray is made of 3004 aluminum alloy, which is light in weight, corrosion-resistant, not easy to rust in a humid environment, and more durable. 3004 aluminum plate can be used for kitchen utensils, food and chemical product processing and storage devices, cake trays, etc.

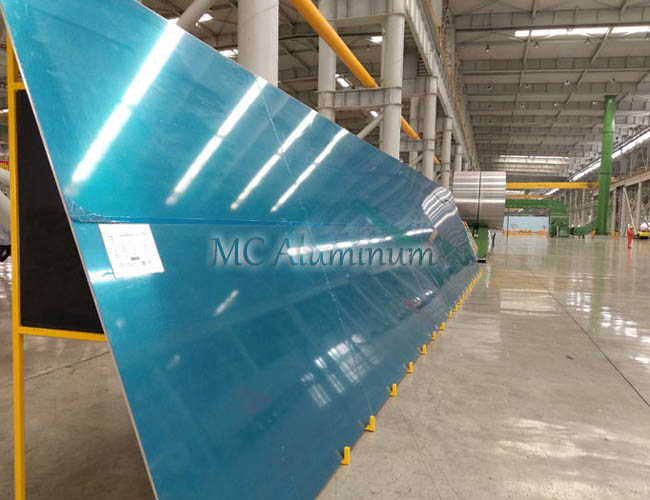

MC Aluminum is an aluminum alloy manufacturer integrating R&D, production and sales. The manufacturer has strong strength, complete product models, and high quality. It can be customized according to customer needs. It is exported to many overseas countries and regions. Old customers come to consult and order.

Contact Us