What are the categories of aluminum strips?

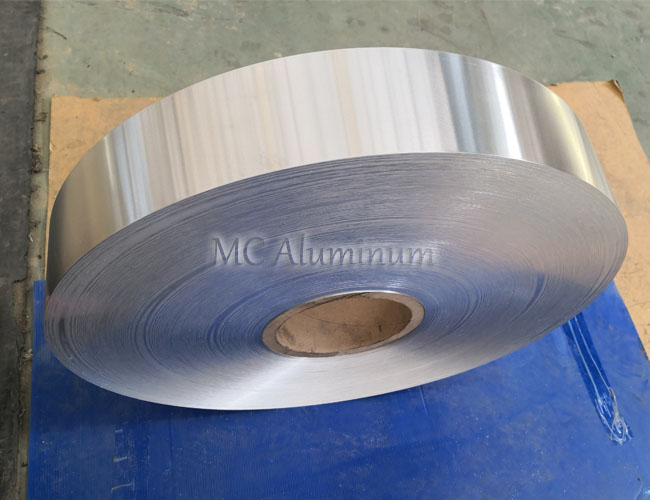

Aluminum strip refers to a strip material made of aluminum as the main component. It has the advantages of light weight, corrosion resistance, good thermal conductivity, and good ductility. It is widely used in aerospace, shipbuilding, automotive industry, architectural decoration, packaging and other fields.

Commonly used aluminum strip alloy grades are 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, etc. Common states are O state and H state, etc. The thickness can be customized, and the width range is 10-800mm.

According to different production processes and usage characteristics, aluminum strips can be mainly divided into the following categories:

1. Surface-treated aluminum strip: Surface-treated aluminum strip is obtained after oxidation, pickling, wire drawing, spraying and other treatment processes on the surface of the aluminum strip. It is often used in architectural decoration, billboard production and other fields. Surface-treated aluminum strips usually have different colors and textures to choose from, which can meet different decoration needs.

2. Cold-rolled aluminum strip: Cold-rolled aluminum strip is an aluminum strip made by cold rolling production process. It has high strength and hardness and is often used in the manufacture of mechanical parts, automotive parts and other fields. Cold-rolled aluminum strip has a smooth surface and precise size, which is suitable for processing and manufacturing fields with high requirements.

3. Hot-rolled aluminum strip: Hot-rolled aluminum strip is an aluminum strip made by hot rolling production process. It has good plasticity and toughness and is suitable for processing processes such as stretching and bending. Hot-rolled aluminum strip is often used in rolling manufacturing, aerospace and other fields, and has important application value.

4. Aluminum alloy strip: Aluminum alloy strip refers to a strip material with aluminum as the main component and alloyed by adding other alloy elements. Aluminum alloy strip usually has higher strength, hardness and heat resistance, and is often used in aerospace, automobile manufacturing, shipbuilding and other fields.

5. Electrical aluminum strip: Electrical aluminum strip refers to aluminum strip used for electrical insulation materials. It has good conductivity and insulation properties and is suitable for insulation protection in the power field.

6. Thin strip and thick strip: According to the thickness of the aluminum strip, it can be divided into thin strip and thick strip. Thin strips usually refer to aluminum strips with a thickness of less than 3mm, which are suitable for electronic products, packaging materials and other fields; thick strips usually refer to aluminum strips with a thickness of more than 3mm, which are suitable for shipbuilding, architectural decoration and other fields.

Aluminum strip production process:

Aluminum ingots--melting and casting--hot rolling--cold rolling--annealing treatment--cutting and straightening--surface treatment (cleaning, coating or oxidation treatment)--inspection and packaging

Contact Us