What are the differences between 6061 aluminum sheet and 6063 aluminum sheet?

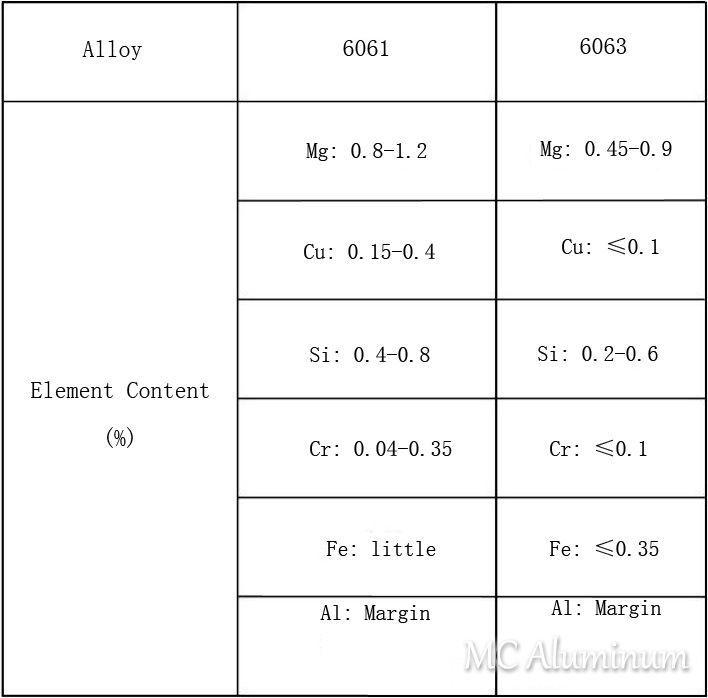

1.Chemical composition

Series 6 aluminum alloys are heat-treatable reinforced alloys of moderate strength. Magnesium has a significant effect on strengthening aluminum alloys, and zinc and copper also have a significant strengthening effect on aluminum alloys.

As can be seen from the above table, 6061 has more alloying elements than 6063. From the content of magnesium and silicon, about 6061 is 30~50% more than 6063. The most direct effect is that the strengthening effect of 6061 is greater than that of 6063.

2. Mechanical properties

The mechanical properties of metal profiles include hardness, strength, ductility, plasticity, fatigue strength, yield strength, etc. The 6063 grade aluminum alloy is better than the 6061 grade aluminum alloy in plasticity, and can meet the high requirements of precision. In terms of strength and processing performance, the aluminum alloy of the 6061 grade is better than the aluminum alloy of the 6063 grade.

3.Scope of use

6061: It is a high-quality aluminum alloy material with high toughness, good weldability and corrosion resistance, and can be used for trucks, ships, aerospace devices, trucks, trams, molds, electronics, furniture and corrosion-resistant structures;

663: It is an aluminum alloy material with very strong comprehensive properties, with high strength, wear resistance, corrosion resistance and high temperature resistance. It can be used for both building profiles and industrial profiles, and is commonly used in building aluminum alloy doors and windows, curtain walls, various industrial frame structures, rail transit, aerospace, military equipment, automatic conveying equipment and other fields. 4. Heat treatment process

4. Heat treatment process

6061 is no longer cold worked after solid solution heat treatment, and can be naturally aged (T4 state), or directly artificially aged, that is, T6 state, which has a large deformation coefficient, high hardness, and is not easy to control;

After 6063 is formed at high temperature, it is cooled, that is, the quenching process. Generally, the cooling method of air cooling is adopted, and then artificial aging treatment is performed, that is, the T5 state.

It can eliminate the internal stress of industrial aluminum profiles to the greatest extent, the deformation coefficient is small, the hardness is not so high, it will not break easily, and the mechanical properties are stronger, but 6063 also adopts the T6 treatment method, and its deformation coefficient will also become larger. , the hardness is higher, and the fracture phenomenon is more likely to occur than T5.

5.Other aspects

Surface treatment: 6061 and 6063 have good oxidation properties. The surface adhesion of 6063 aluminum alloy is slightly higher than that of 6061 aluminum plate, so the oxidation ability is extremely strong.

Machinability: Overall good, 6061 is better.

Corrosion resistance: Generally good, 6063 is slightly better.

Weldability: all can be welded, 6063 is slightly better.

Price: The price of the two is similar, and the current 6063 is slightly more expensive.

How much is a ton of 6 series aluminum sheet?

The price of aluminum plate is composed of aluminum ingot price and processing fee. Aluminum plate manufacturers generally refer to the price of Changjiang aluminum ingots on the day of delivery. Different specifications have different processing fees. When users make an inquiry, if they want a more accurate quotation, they need to provide the specific model, state, thickness, width and length of the required product, which is convenient for manufacturers to calculate.

MC Aluminum specializes in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products, welcome to order!

Contact Us