What is Anodized Aluminum Sheet, Alumina Sheet Price-MC Aluminum

What is Anodized Aluminum Sheet, Alumina Sheet Price -MC Aluminum

Anodizing is an oxidation method of aluminum oxide plate, which refers to the electrochemical oxidation of metal or alloy. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys are exposed to aluminum products (anode) under the action of applied current. The process of forming an oxide film on it.

Anodizing in aluminum oxide plate can not only solve the defects of aluminum surface hardness and wear resistance, but also prolong the service life of aluminum and enhance the aesthetics. It has become an indispensable part of aluminum surface treatment and is currently the most widely used. and a very successful process.

Anodized aluminum sheets are widely used in mechanical parts, aircraft auto parts, precision instruments and radio equipment, architectural decoration, machine casings, lamps and lighting, consumer electronics, handicrafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.

Different trace elements have different effects on anodic oxidation. According to the oxidation effect of various brands, pure aluminum has the best oxidation effect, and because of the high content of zinc in Series 7, zinc is the chemical component that has the greatest influence on the oxidation effect. Therefore, the 7-series oxidation effect is poor.

Commonly used alloys are 1060, 5052, 6061, 6063 and so on.

Advantages of Anodized Aluminum Sheets:

1.Good processability: Anodized aluminum plate has strong decorative properties, moderate hardness, can be easily bent and formed, and can be continuously punched at high speed, which is convenient for direct processing into products without complicated surface treatment, which greatly shortens the production cycle and reduces product Cost of production.

2.Good weather resistance: The anodized aluminum plate with standard thickness oxide film (3μm) will not discolor, corrode, oxidize or rust when used indoors for a long time. The anodized aluminum plate with thick oxide film (10μm) can be used outdoors and can be exposed to sunlight for a long time without discoloration.

3.Strong sense of metal: The surface hardness of the anodized aluminum plate is high, reaching the gem level, with good scratch resistance, no paint on the surface, retaining the metal color of the aluminum plate, highlighting the modern metal feeling, and improving the product grade and added value.

4.High fire resistance: pure metal products, no paint and any chemical substances on the surface, no combustion at 600 degrees high temperature, no toxic gas, in line with fire protection and environmental protection requirements.

5.Strong stain resistance: no fingerprints, no stain marks, easy cleaning and no corrosion spots.

6.Strong applicability: Wide range of uses, suitable for metal aluminum ceilings, curtain wall panels, aluminum-plastic panels, fireproof panels, honeycomb aluminum panels, aluminum veneer panels, electrical panels, cabinet panels, furniture panels, etc.

7.Good decoration: while maintaining the luster and texture of metal, it can be colored into colorful colors.

8.Good transparency: the higher the purity of aluminum, the higher the transparency of the oxide film.

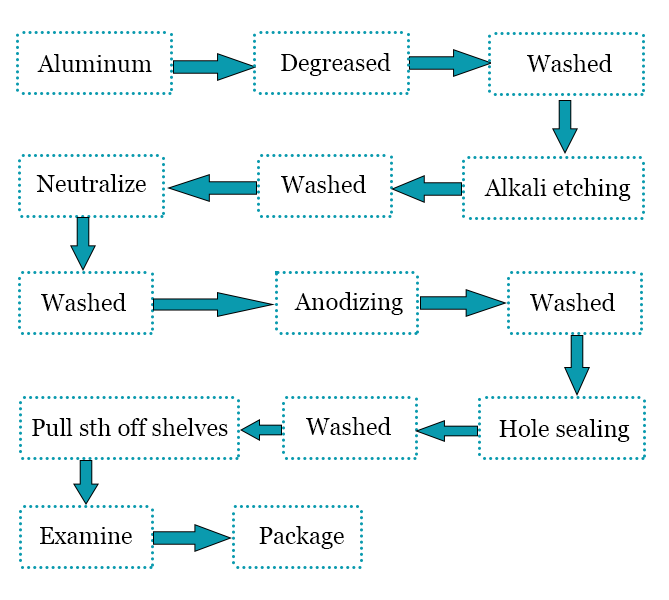

Process flow of anodized aluminum plate:

Contact Us