What is the material of aluminum alloy cans

Cans are currently divided into two categories, aluminum cans and iron cans. Compared with other packaging containers, aluminum cans are more environmentally friendly. As far as their containers are concerned, repeated recycling reduces environmental pollution; in terms of materials used, aluminum The repeated use of materials effectively saves resources.

There are many canned beverages seen in life, such as Coca-Cola, beer, etc. These canned beverages have a common feature, they are all cans, and cans are processed and produced with aluminum alloy materials. Generally, cans are divided into three parts: Can body, can lid, pull ring, the aluminum used for each part is different.

The aluminum materials for pop cans currently produced by aluminum manufacturers for pop cans are divided into 3 series and 5 series of aluminum alloys:

1.The 3 series is divided into 3004 and 3104 aluminum materials. 3104 aluminum is used as the aluminum material for the can body. It has good formability, weldability and corrosion resistance. It is mostly used for processing and requires good formability, high corrosion resistance and weldability. A good product, used in cans can well prevent the oxidation and corrosion of carbonated beverages on the cans. The thickness is about 0.2-0.3mm, and 3004 aluminum is used as the aluminum material for can lids, and the thickness range is between 0.25-0.45mm.

2.The 5 series is divided into 5052 and 5182 aluminum materials. Both 5052 and 5182 are used as cover materials with a thickness between 0.2-0.25mm. The 5 series is an aluminum-magnesium alloy with good compressive strength and corrosion resistance. They are all made of 5182 aluminum coil, and the pull ring is embedded on the lid to use the strength of the pull ring to push the lid open, so the 5182 aluminum plate is the most suitable, with the advantages of high strength, good toughness, and not easy to deform.

What are the advantages of aluminum plates for cans?

1. High flatness, good shape, advanced grinding machine equipment to ensure flat shape, precise thickness control, and small thickness tolerance.

2. Easy to process, stable performance, high strength aluminum alloy, corrosion resistance, Mingtai strictly controls each process, so that the product has appropriate strength and formability.

3. Easy to recycle, green and environmentally friendly, resistant to acid and alkali corrosion, durable, recyclable, economical and environmentally friendly

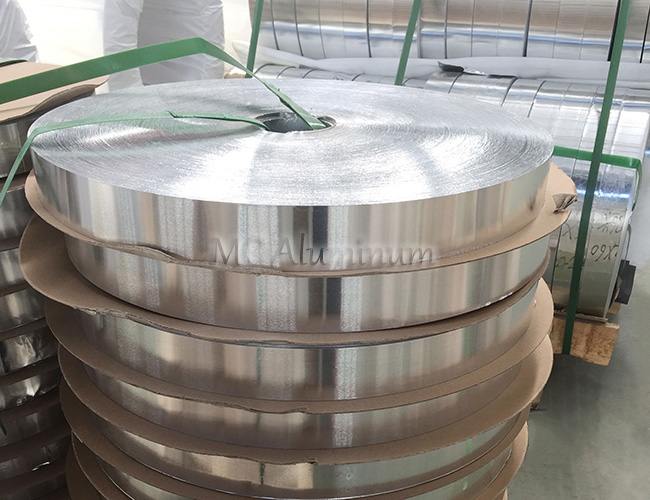

MC Aluminum mainly produces raw materials of aluminum alloy cans and aluminum plates, and does not do post-processing of finished products. The aluminum plate products produced have a flat plate shape, no marks, pitting. Production can be customized according to customer needs. If you have needs for aluminum plate products, please feel free to leave a message.

Contact Us