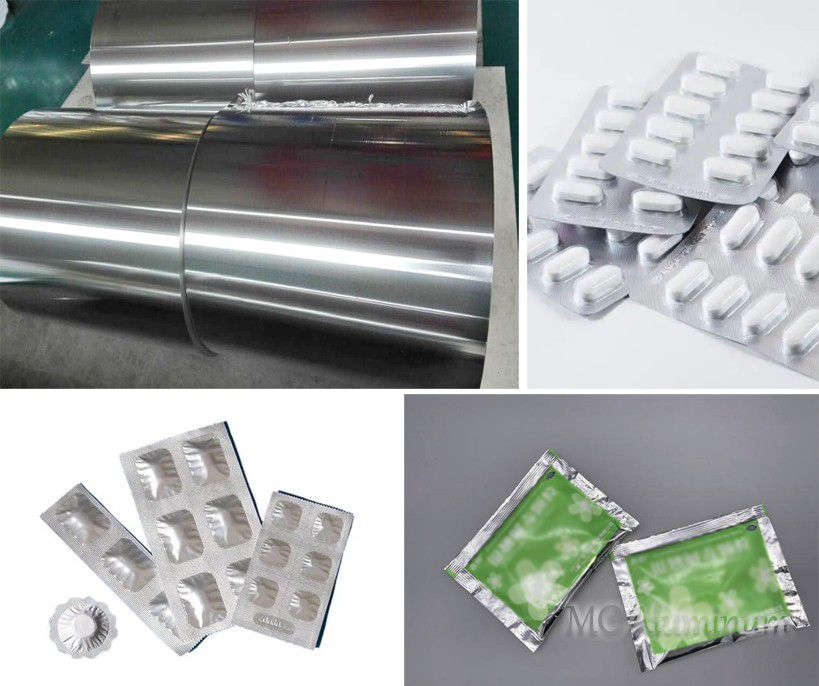

Zero pinhole pharmaceutical packaging aluminum foil 8011

Aluminum foil has a highly dense metal crystal structure, which can isolate air and moisture, and has good light-shielding properties, blocking external interference factors, and is widely used in various packaging.

Pharmaceutical aluminum-plastic blister packaging has many advantages such as beautiful appearance, good barrier properties, and convenience in use and carrying. It is widely used in the pharmaceutical industry and is currently one of the main packaging methods for solid dosage forms such as pharmaceutical tablets and capsules. Pharmaceutical packaging aluminum foil (PTP aluminum foil) uses 8011 aluminum foil as the interlayer, the state is H18, O, the thickness range is 0.016-0.04mm, and it has the advantages of high heat sealing strength, no pinholes, and good sealing.

Requirement for pinhole degree of pharmaceutical packaging aluminum foil:

The requirement for pinhole degree of pharmaceutical packaging aluminum foil is that the pinhole with a diameter of 0.1~0.3mm does not exceed 1/m2. Pinholes are tiny holes on the surface of aluminum foil, which may cause external factors such as oxygen, water vapor and light to invade the interior of the package, thereby affecting the quality and safety of the medicine. Therefore, the requirements for pinhole degree are very strict.

Factors affecting the pinhole degree of medicinal aluminum foil:

1. Aluminum foil thickness: As the thickness of aluminum foil decreases, the number of pinholes increases rapidly. When the thickness is above 0.02mm, the aluminum foil can be completely pinhole-free.

2. Metallurgical quality of billet: Foreign matter such as dust, large particles, or inclusions, bubbles and oxide films during casting and rolling will cause pinholes.

3. Aluminum foil production process: The rationality of the cold rolling process has a direct impact on the number of pinholes in aluminum foil, such as the convexity of the roller, surface roughness, annealing process, etc.

Advantages of aluminum foil for pharmaceutical packaging:

1. High barrier properties

2. High and low temperature resistance

3. Good sealing properties

4. Non-toxic and tasteless, safe and hygienic

5. Good light-shielding properties

6. Convenient for patients to take medicine

7. Strong mechanical properties

MC Aluminum is a large manufacturer of raw materials for pharmaceutical packaging aluminum foil. The 8011 aluminum foil it produces is food grade, with a clean surface, uniform color, no spots, flat and pinhole-free. It can accept large orders of 1-2000 tons, direct sales from the manufacturer, preferential prices, and export overseas.

Contact Us