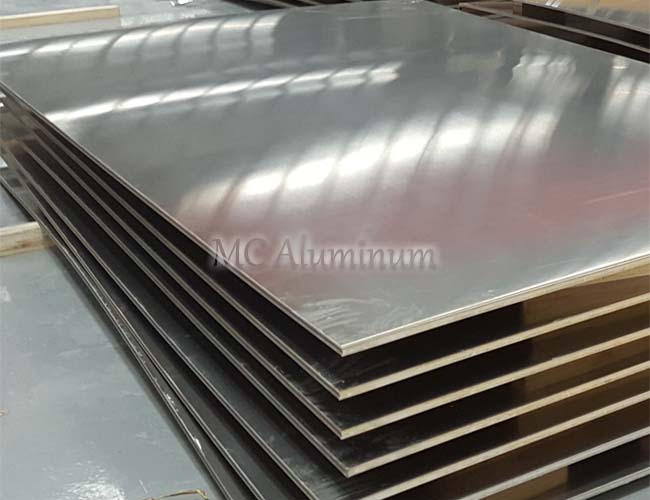

5052 alumina plate inventory

Anodizing is currently a common method for surface treatment of aluminum alloys. 5052 anodic alumina plate can be divided into ordinary anodized and hard anodized. The color film obtained by electrolytic oxidation coloring of aluminum and aluminum alloy has good wear resistance, light resistance, heat resistance and corrosion resistance, and is widely used in the decoration and anti-corrosion of modern architectural aluminum profiles. However, the 5052 anodized film has high porosity and adsorption capacity, and is easily eroded by pollution and corrosive media. It must be sealed to improve corrosion resistance, anti-pollution ability and fix pigment bodies.

Anodized aluminum sheets are widely used in mechanical parts, aircraft and auto parts, precision instruments and radio equipment, architectural decoration, machine shells, lighting fixtures, consumer electronics, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

The 5052 alumina plate produced by MC Aluminum has the following advantages:

1.High hardness, good corrosion resistance.

2.Anti-pollution and fire prevention, high safety.

3.Good weather resistance, suitable for processing.

MC Aluminum is a manufacturer specializing in the production of aluminum plates and can accept customization. The 5052 aluminum alloy produced has the advantages of easy coloring, corrosion resistance, and oxidation resistance. Compared with 1-series and 3-series aluminum alloys, the hardness is higher, so the processing cost higher. MC Aluminum has absolute price concessions and quality assurance! If you have needs for aluminum products, please email us. (sales@alummc.com)

Contact Us