5052 vs. 5086 Marine Aluminum Plate: Which Is Best for Your Shipbuilding Project?

The 5xxx series aluminum alloys, primarily alloyed with magnesium, are widely regarded as ideal marine materials due to their natural resistance to saltwater corrosion and excellent weldability. The 5 series marine aluminum alloy, with its low density, high strength-to-weight ratio and excellent corrosion resistance, helps to significantly reduce the weight of the hull, thereby increasing cargo capacity, improving stability and increasing speed. It is increasingly becoming the preferred material for ship construction.

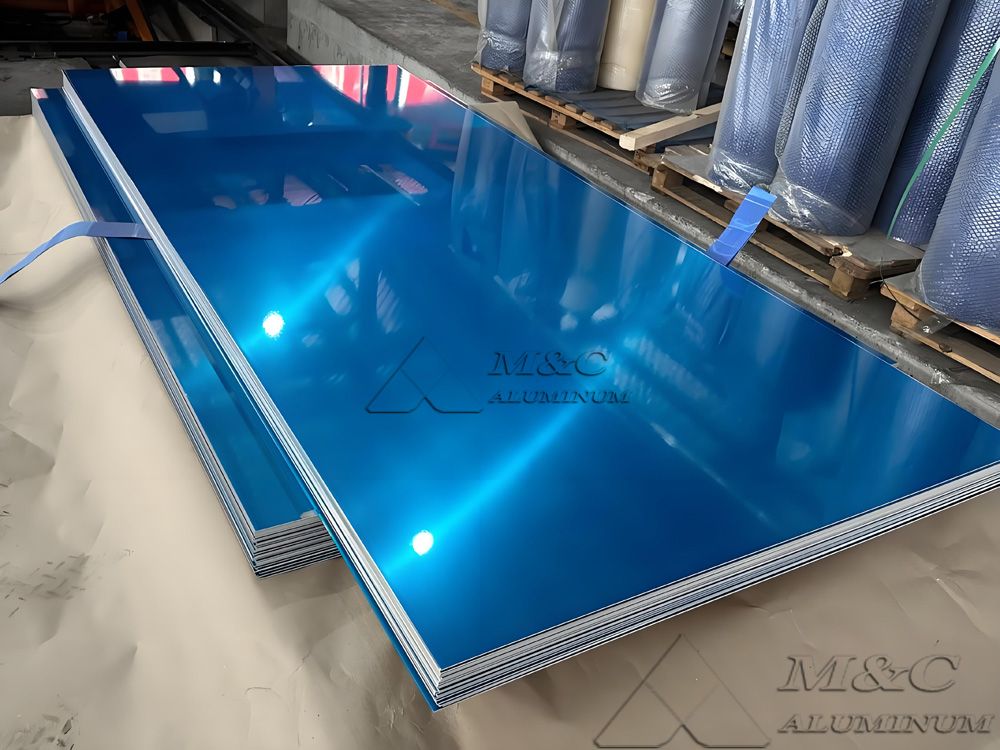

5052 Marine-Grade Aluminum Plate

5052 aluminum plate is a typical aluminum-magnesium alloy offering moderate strength, excellent corrosion resistance, and good workability, making it one of the most widely used aluminum alloys in the shipbuilding industry. Its corrosion resistance is particularly suited for marine and humid environments, making it a key material for lightweight vessel manufacturing.

5086 Marine-Grade Aluminum Plate

5086 aluminum plate is a high-magnesium aluminum alloy known for exceptional corrosion resistance and high strength, ideal for structural components requiring superior strength. It ranks among the best in corrosion resistance across the 5xxx series and is the preferred material for naval vessels and advanced marine engineering.

MC Aluminum offers 5086 plates in marine-grade tempers such as H116 and H321, all certified by BV, DNV, ABS, and other international classification societies.

Marine-Grade Aluminum Plate Specifications

| Alloy | 5052 | 5086 |

| Temper | H32, H34, etc. | H116, H112, H321 |

| Thickness | 3-50mm | |

| Width | 1000-2650mm | |

| Length | 1000-16000mm | |

| Processing | Cutting, bending, film coating | |

| Surface Options | Anodized, embossed, etc. | |

| Certifications | BV / DNV / ABS / LR, etc. | |

| MOQ | 1-3 tons | |

5052 vs. 5086: Head-to-Head Comparison

1.Mechanical Properties

| Alloy | 5052-H32/H34 | 5086-H32/H116 |

| Main Components | Mg 2.2-2.8%, Cr 0.15% | Mg 3.5-4.5%, Mn 0.4% |

| Yield Strength (MPa) | 215-260 (H34) | 240-285 (H116) |

| Tensile Strength (MPa) | 260-290 | 270-315 |

| Elongation (%) | 10-12% (H34) | 12-14% (H116) |

| Density (g/cm³) | 2.68 | 2.66 |

Conclusion: There is no “better” material-only a better fit for specific applications.

Choose 5086 for rigidity and load-bearing needs, and 5052 for flexibility and secondary structural elements.

2.Corrosion Resistance

5086, with higher magnesium content, forms a denser oxide film, offering superior protection in extreme conditions such as high salt spray, humidity, and long-term seawater immersion. It is widely used in naval ships, coast guard vessels, and deep-sea recovery systems.

5052 also offers good corrosion resistance and is suitable for coastal applications, though less durable under highly corrosive environments compared to 5086.

3.Strength and Structural Applications

If your application demands higher structural strength and pressure resistance, 5086 is the ideal choice, particularly for load-bearing parts like keels, hull frames, and lower decks.

5052, with its moderate strength, is better suited for cabin partitions, stairs, handrails, window frames, and other non-load-bearing components.

4.Processing and Weldability

Both 5052 and 5086 exhibit excellent weldability and are compatible with TIG/MIG welding. Their post-weld performance remains stable, though 5086 retains strength better and is less prone to cracking, making it ideal for continuous welding and large structural assemblies.

5052 Advantages: Softer, easier to bend, punch, and stamp.

5086 Advantages: Minimal strength loss after welding, corrosion resistance, and no deformation.

5.Real-World Applications

5.5052 Marine Aluminum Plate:

Cabin walls, stairs, railings, galley equipment, lockers, window frames, etc.

5086 Marine Aluminum Plate:

Warship decks, hull skeleton, floating bridges, offshore platform bases, oil tanks, propulsion covers, keel reinforcements, etc.

6.Cost Analysis

Price: 5052 is relatively affordable due to its lower magnesium content and mature processing technology.

Long-term cost-effectiveness: While 5086 has a slightly higher initial cost, it offers low maintenance costs and a long lifespan, making it suitable for high-value vessels or export orders.

Contact Us