ACP Manufacturer

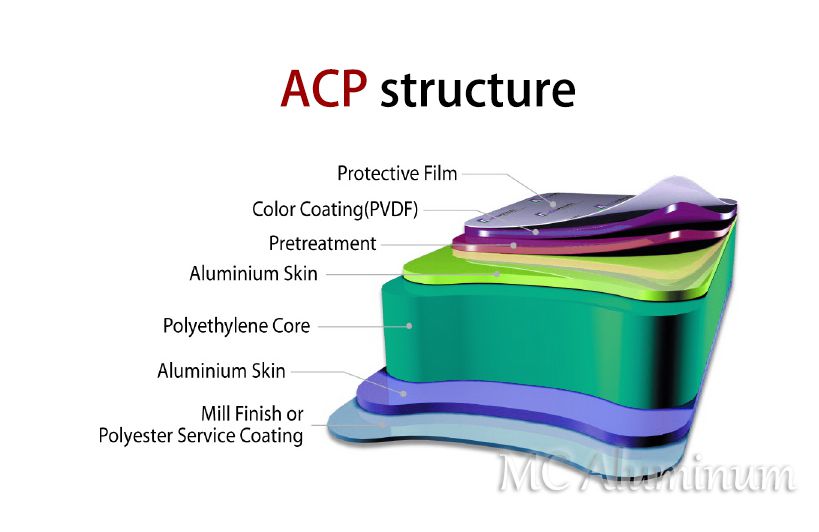

Aluminum Composite Panel (ACP), also known as aluminum-plastic panel, is a new environmentally friendly material laminated by aluminum sheet (5083 and 5080 aluminum alloy) and polyethylene (PE) plastic core. Depending on the use, the surface of aluminum composite panel can have PVDF (polyvinylidene fluoride) coating or PE coating. In order to protect the surface of aluminum composite panel from damage, manufacturers usually cover the surface with a protective film.

As a new decorative material, aluminum composite panel is not only widely used in the construction industry, but also plays an important role in the advertising printing market. Generally, the panel thickness of aluminum composite panel is between 1 and 10 mm. For architectural applications, 3 mm or thicker panels are recommended. While in the advertising market, 3 mm or thinner panels are usually sufficient.

Characteristics of ACP:

1. Lightweight and easy to install

2. Corrosion resistance and weather resistance

3. Beautiful and diverse appearance

4. Excellent processing performance

5. Wide application

6. Excellent fire resistance

Compared with panels with PE coating, aluminum composite panels with PVDF coating have the following advantages:

1. Anti-scratch: more wear-resistant and less prone to scratches on the surface.

2. Impact resistance: more able to withstand physical impact.

3. Weather resistance: stable under various climatic conditions.

4. Corrosion resistance: able to resist the erosion of chemicals.

Therefore, aluminum composite panels with PVDF coating are more suitable for outdoor use.

The middle part of the aluminum composite panel is a plastic core, which is divided into ordinary PE core and fireproof core. In order to improve the strength and durability of aluminum composite panels, customers usually require a plastic core that is not easy to break. These panels can be processed by a variety of processing methods, such as cutting, drilling, punching, slotting and bending. If the core of the aluminum composite panel used in the curtain wall industry is easily broken, it may lead to unimaginable consequences, affecting the safety and beauty of the building.

Contact Us