Advantages and disadvantages of aluminum foil packaging

Aluminum foil is a material made of metal aluminum directly pressed into thin sheets. It has a soft texture and good ductility. It is widely used in food packaging, pharmaceutical packaging, cable foil, air conditioning foil, battery foil, building insulation layer, etc. Especially in the packaging industry, the application is very common.

Aluminum foil for packaging is made from electrolytic aluminum with a purity of 99.0%-99.7%, which is produced through multiple rolling processes. Commonly used alloy 1060 aluminum foil, 1100, 3003, 8011, 8021 aluminum foil, etc. This kind of packaging is not only moisture-proof, air-tight and light-shielding, but also has the advantages of fragrance retention, non-toxic and odorless. Such advantages are unmatched by any other existing packaging materials. Below, we introduce in detail the advantages and disadvantages of aluminum foil packaging.

1. Advantages

1. Characteristics of aluminum foil: light weight, good ductility, and thin thickness.

2. It has good light-shielding properties and the reflectivity can reach 95%.

3. It has strong barrier properties and can effectively protect food and avoid bacterial contamination.

4. It has the characteristics of moisture-proof, air-tight and fragrance-preserving, which can prevent the packaging contents from absorbing moisture, oxidation, volatilization and deterioration.

5. Aluminum foil has a shiny metallic luster and is highly decorative.

6. Aluminum foil is non-toxic, tasteless and odorless.

7. Aluminum foil is easy to process and can be used with various

Plastic film and paper composite.

2. Disadvantages

1. Aluminum foil has low strength and is easily torn. It cannot be used alone to package products.

2. It is easy to break when folded, causing holes, and is not resistant to acid and alkali.

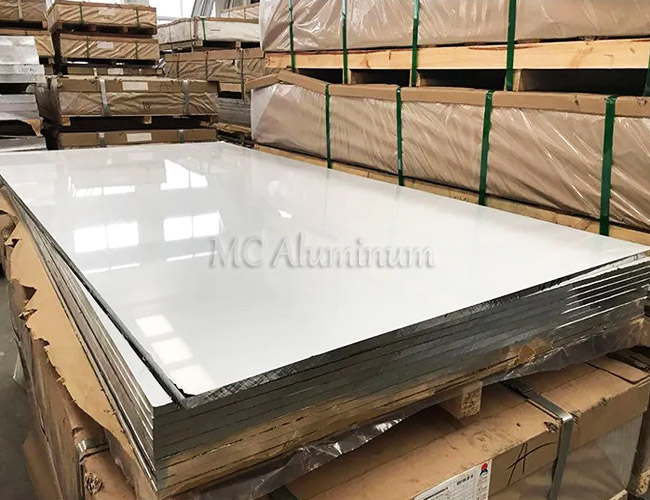

MC Aluminum is a large-scale manufacturer of aluminum foil raw materials for food packaging. The raw materials of aluminum foil for food packaging are mainly 1 series, 3 series and 8 series products. The softness and hardness of the alloy, that is, the alloy state, is selected according to the needs of the packaged food. The three commonly used states are H14, H16 and H18. The product has multiple advantages such as food grade, clean degreasing, less voids, good product shape, and no deformation when cut. It can be exported overseas and the price is favorable.

Contact Us