Aluminum alloy food mold

Molds are tools used to make shaped objects and are widely used in industrial production. In daily life, people also often use molds to make delicacies with various exquisite patterns, such as cake molds and so on. The raw materials of food molds are mostly made of wood, and now food-grade aluminum or silica gel is also used. Because aluminum alloy has high temperature resistance, good thermal conductivity, uniform heating, strong durability and high safety, it is very popular in the market and widely used in cake baking.

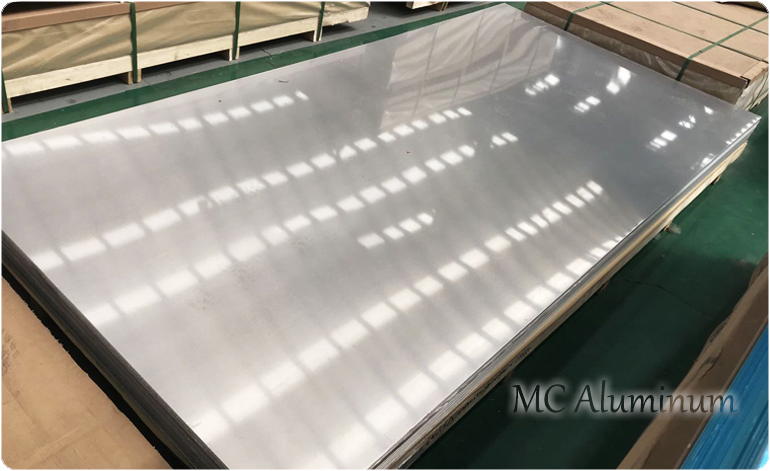

The food molds on the market usually use 6061 aluminum plate and 6082 aluminum plate, both of which belong to Al-Mg-Si alloy, with medium strength, good plasticity and excellent corrosion resistance, high toughness and no deformation after processing, easy to apply color film, Excellent oxidation effect and other excellent characteristics. Mainly used in transportation, structural engineering industry, shipbuilding, mold processing, etc.

Aluminum sheet specifications for food molds

Alloy: 6016, 6082

Temper: O, H*2, H*4, H18, H111, H112

Thickness: 3-600mm

Width: 500-2650mm

Length: 500-16000mm

The surface of the aluminum alloy food mold is anodized to form a dense oxide film, which has good material uniformity and is durable. Moreover, aluminum is resistant to high temperature, has good thermal conductivity, and is more evenly heated, which is conducive to cake baking. From the perspective of wide use, aluminum alloy is cheap, and aluminum molds are widely used. From the perspective of environmental protection, aluminum can be recycled and reused, which is environmentally friendly and energy-saving, so it is favored by the market.

MC Aluminum is a large-scale aluminum plate manufacturer with rich processing experience, high technical level, exquisite workmanship, guaranteed product quality, complete product models, fast delivery, large output, and exported to many overseas countries and regions. Users can enjoy the factory discounted price.

Contact Us