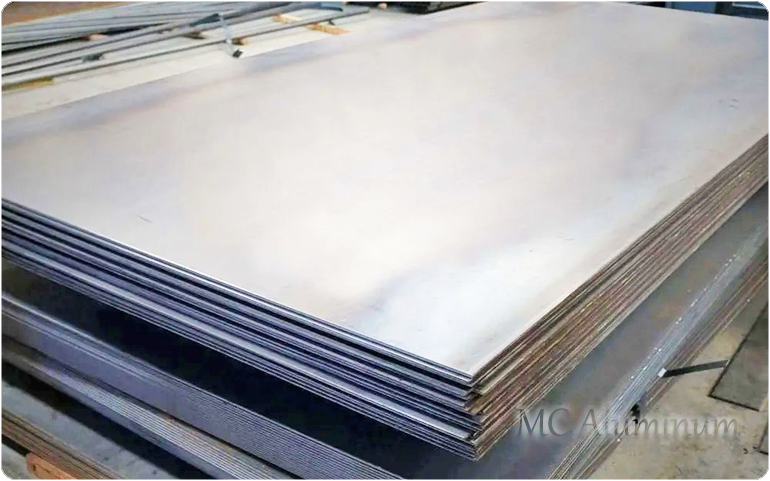

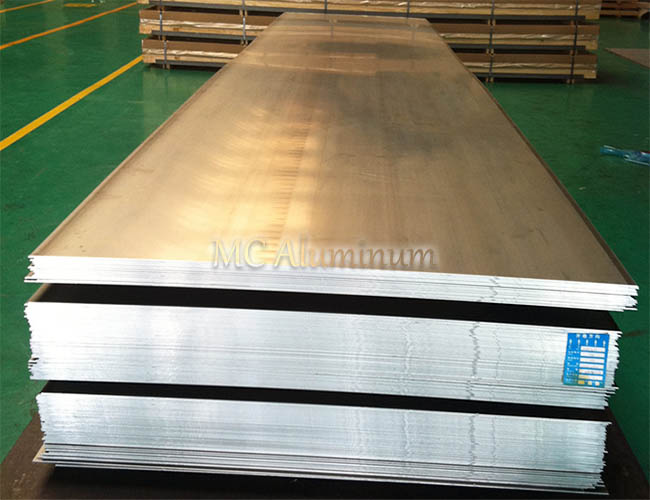

Deep drawn aluminum plate with high quality

Deep drawing aluminum plates rely on presses and molds to exert pressure on the plates to cause plastic deformation and separation, thereby obtaining plates of the required shape and size. The car body, chassis, and aluminum materials used in the motor are all stamped.

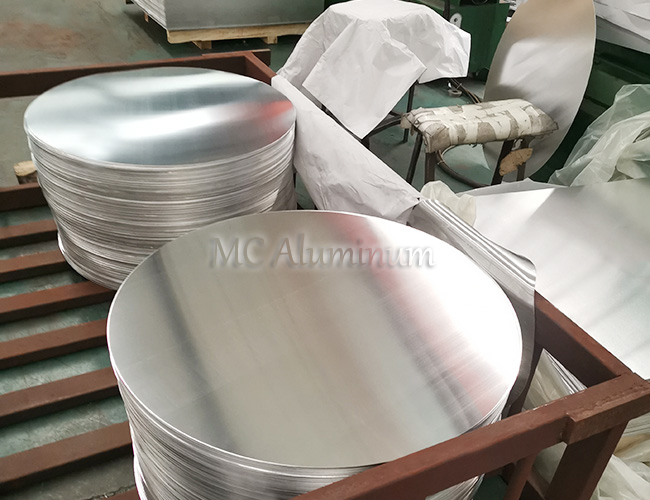

Deep-drawn aluminum plates are mainly concentrated in 1 series, 3 series, 5 series and 8 series aluminum alloys, such as 1050, 1060, 3003, 5052, 8011, etc. are common deep-drawn aluminum plates. The cold-rolled deep-drawn aluminum plates produced by Qingyan Technology use soaking technology to eliminate internal stress, while reducing intra-granular segregation and structural inhomogeneity, improving the stretchability and plasticity of the product. The final product has good flatness, uniform color and good stretchability. Due to its good productivity, it is suitable for mass production and can be made into lightweight and highly rigid products. It is often used in storage devices, tableware, electrical appliances, lighting parts and other fields.

Deep drawing aluminum plate applications:

Deep-drawn aluminum sheets have good formability, corrosion resistance, weldability, electrical conductivity, and thermal conductivity. They can be gas welded, hydrogen atomic welded, and contact welded. They can be used to manufacture aircraft fuel tanks, oil pipes, and sheet metal parts for transportation vehicles and ships. , instruments, street light brackets and rivets, hardware products, electrical casings, pattern boards, umbrella frames, special materials for transportation equipment, silos, LCD back panels, sound insulation barriers, daily necessities, lighting fixtures, reflective panels, decorations, chemical industry containers , heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products.

Deep drawing aluminum plate performance characteristics:

1. It has high electrical conductivity and thermal conductivity, good plasticity, and is easy to withstand various pressure processing, bending and extension;

2. It has good welding performance and is suitable for gas welding, hydrogen atom welding and resistance welding;

3. Has good corrosion resistance;

4. Mature technology, good quality and low price;

5. Good forming processing characteristics, high corrosion resistance, good weldability and electrical conductivity;

6. The area of the thermal neutron absorption boundary is small and the appearance is beautiful in color;

7. It has good plasticity, excellent forming effect, and is easy to withstand various pressure processing, bending and stretching;

8. The processing technology is mature and the price has a great advantage compared with other high-end aluminum alloys.

MC Aluminum is a professional aluminum plate manufacturer, producing 1-8 series aluminum plates. The product has a smooth shape, clean degreasing, no black wire, burrs, and no curling when cutting. The product models are complete and can be customized according to customer needs. They are exported to many overseas countries and regions. Product mailing services are provided and after-sales are guaranteed. Users can order with confidence and look forward to your contact.

Contact Us