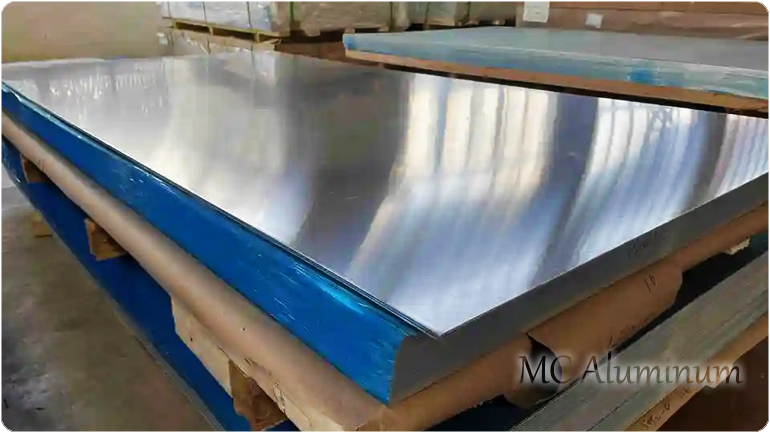

Aluminum alloy plate of electrical appliance shell

Aluminum plate has the advantages of light weight, good processability and strong recyclability, and is widely used in life. Aluminum plates are divided into eight series according to the content of alloying elements, and each series has multiple brands. According to the different properties, there are certain differences in uses. In recent years, aluminum plates have been widely used in household appliances, which are usually used to manufacture electrical enclosures. The commonly used brands are 5052 aluminum plates, 5083 aluminum plates and 3003 aluminum plates.

5052 aluminum sheet is AL-Mg alloy aluminum plate, which is a kind of rust-proof aluminum widely used. It has good formability, corrosion resistance, weldability and medium strength. It is used to manufacture aircraft fuel tanks, oil pipes, sheet metal parts of traffic vehicles and ships, instruments, street lamp brackets and rivets, hardware products, electrical housings and so on.

5083 aluminum sheet also belongs to AL-Mg alloy. This alloy has high strength, especially high plasticity and corrosion resistance, and cannot be strengthened by heat treatment. It has good plasticity in semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, good weldability, poor machinability and polishing. Uses are mainly used for low-load parts that require high plasticity and good weldability and work in liquid or gas media, such as oil tanks, gasoline or lubricating oil pipes, various liquid containers and other low-load parts made by deep drawing: wires are used for rivets.

3003 aluminum sheet is a representative product of AL-MN series, which has good stamping and tensile properties, and is very common in some metal shells. At the same time, this material has good corrosion resistance and excellent weldability. It is used to punch aluminum shells of capacitors, with light weight, good sealing performance, high temperature resistance and corrosion resistance, and has become the first choice of many enterprises.

Advantages of aluminum electrical enclosure:

1. Light weight and convenient transportation.

2, corrosion resistance and long service life.

3. Good weldability and excellent sealing performance.

4, good heat dissipation ability, prevent the capacitor from overheating.

It is precisely because of the advantages of corrosion resistance, light weight, long life and high safety that more and more users choose to use aluminum capacitor shells.

MC Aluminum specializes in producing 1-8 series aluminum plates. The product specifications are complete and the production capacity is huge. It can be customized according to customers' needs to meet your individual needs. The products are exported overseas, and the after-sales service is guaranteed. Users can enjoy the ex-factory preferential price. You are welcome to leave a message and contact us at any time.

Contact Us