Aluminum anti-counterfeit bottle cap material

Aluminum anti-counterfeit bottle caps can be made of 1060 aluminum foil, 1235 aluminum foil, 8011 aluminum foil, 3003 aluminum foil, 3105 aluminum sheet and other materials, used for sealing packages of glass bottles or plastic bottles with threaded openings, and there is a complete anti-theft ring on the bottle cap , with anti-counterfeiting marks on it. When it is opened, the anti-theft ring is broken, and the bottle cap cannot be restored to its original packaging form. This method prevents theft and counterfeiting, so it becomes an anti-theft bottle cap. The anti-theft bottle cap has the advantages of hygiene, safety, practicality, convenience and reliability, etc., all thanks to the excellent aluminum bottle cap material. It is mainly used for the packaging of wine, beverages (with or without steam) and medicine and health care products.

Anti-counterfeiting bottle cap materials are all hard, with hardness between H14-H24, tensile strength between 110-320, and elongation generally not less than 4.

Aluminum bottle caps are mostly processed on a production line with a high degree of automation, so the requirements for the strength, elongation and dimensional deviation of the material are very strict, otherwise cracks or creases will occur during deep drawing. In order to ensure the convenience of printing after the bottle cap is formed, the aluminum plate of the bottle cap material is required to have a flat surface without rolling marks, scratches and stains. The production of aluminum bottle cap materials can be made by hot rolling or continuous casting and rolling, respectively, and then rolled by cold rolling. Production practice shows that the hot-rolled billet is better than the cast-rolled billet in the use effect of the anti-theft cover.

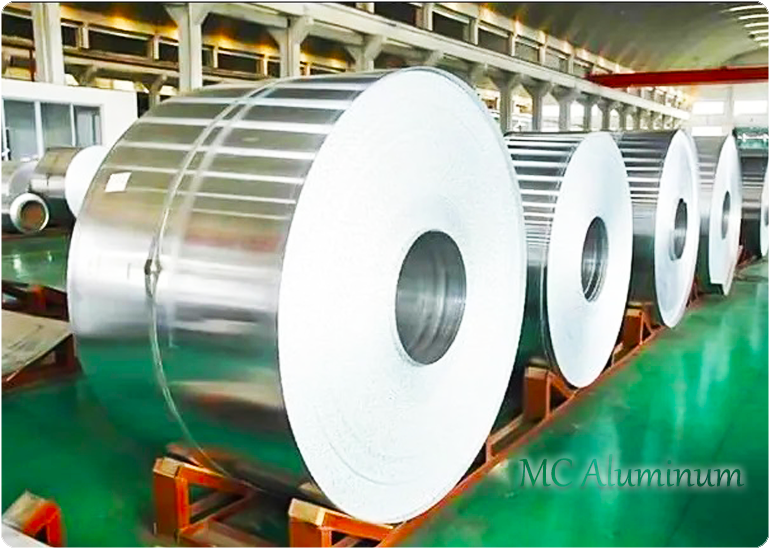

MC Aluminum is a professional manufacturer of aluminum foil, with stable product quality, complete models, and global exports. Users can enjoy preferential prices from the factory and can purchase with confidence.

MC Aluminum does not do late-stage lamination, printing, gluing and other processing techniques, but only provides aluminum substrates.

Contact Us