Aluminum Circles for Cookware Bottoms: 1050 & 1060

Aluminum circles serve as a key material for cookware bottoms and bodies, widely used in the production of non-stick pans, soup pots, steamers, milk pots, and inner linings of rice cookers. Among them, 1050 and 1060 aluminum circles are the most commonly used alloys, dominating the cookware industry due to their excellent ductility, thermal conductivity, and cost-effectiveness.

For some high-end stainless steel cookware, the bottom typically has at least three layers: two layers of steel with aluminum in between as the heat-conducting material. Aluminum has excellent thermal conductivity but is non-magnetic, so it does not work with induction, whereas steel is magnetic, making such cookware suitable for induction cooktops.

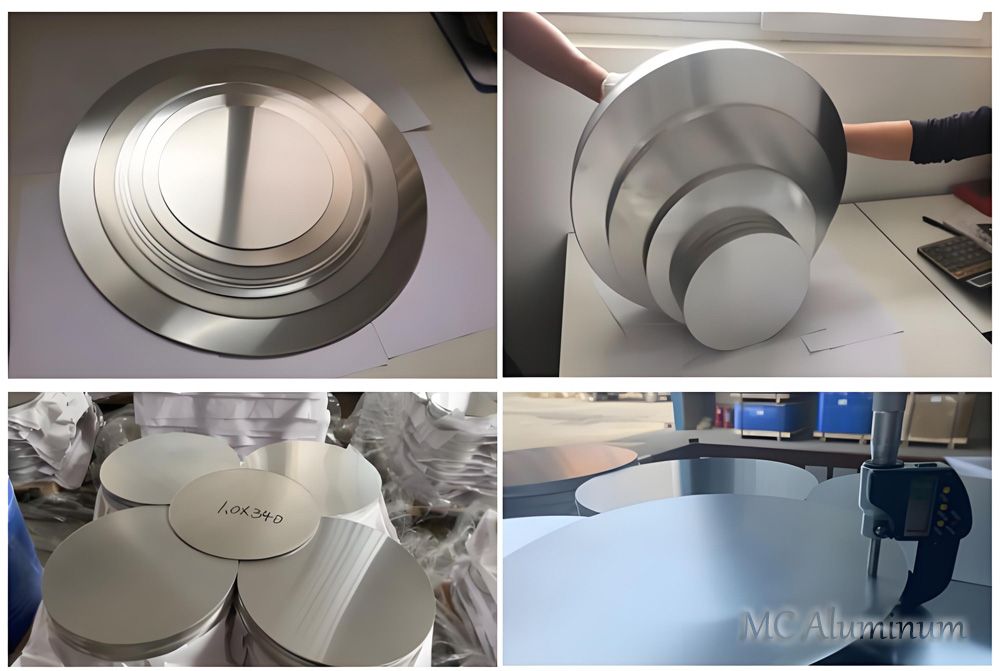

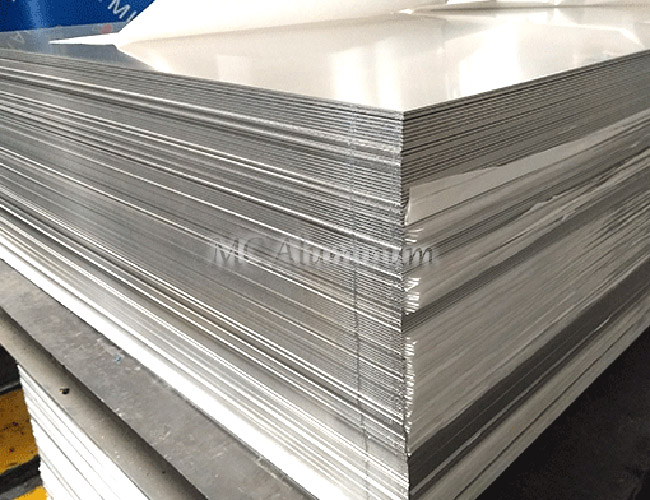

In cookware manufacturing, 1050 and 1060 aluminum circles are commonly produced using hot-rolling or cast-rolling processes, available in tempers such as O, H12, H14, etc. The O temper (annealed) is softer with excellent ductility, ideal for deep stamping and complex forming. H tempers (hardened) offer higher strength, suitable for cookware requiring greater rigidity. Typical thickness ranges from 0.5mm to 6mm, with diameters from 100mm to 980mm, adjustable according to cookware size.

Functions and Features of Aluminum Circles for Cookware Bottoms

1. Excellent Thermal Conductivity: Aluminum's high thermal conductivity ensures even heating, reducing hot spots and improving cooking efficiency.

2. Lightweight Design: Low density makes cookware easy to handle and maneuver.

3. Good Formability: High ductility suits spinning, deep stamping, and pressing, allowing diverse bottom shapes.

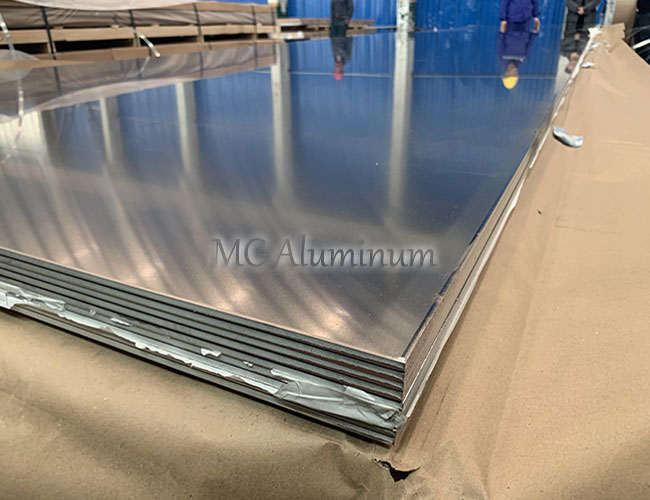

4. High Flatness: Precision rolling ensures flat bottoms that fit heating surfaces well, improving heat transfer efficiency.

5. Corrosion Resistance & Surface Treatment: Can undergo anodizing, polishing, or coating to enhance durability and appearance.

6. Compatibility with Composite Materials: Can be combined with stainless steel or copper in multi-layer bottoms, balancing heat conduction and appearance.

7. Cost-Effective & Suitable for Mass Production: Low material cost and high production efficiency make it ideal for large-scale cookware manufacturing.

Specifications

| Alloy | 1050, 1060 |

| Temper | O, H12, H14, H18, H24 |

| Thickness | 0.5mm - 6.0mm |

| Diameter | 50mm - 1600mm (commonly 200mm - 700mm) |

| Delivery Time | 30-45 days after deposit |

| Packaging | Standard export wooden pallets or per customer requirements |

| Material | Produced with advanced machinery and high-quality aluminum coils |

| Surface | Bright and smooth, free from white rust, oil stains, or edge damage |

| Samples | Available |

| MOQ | 1-3 tons |

Surface Treatments for Cookware Aluminum Circles

Anodizing / Hard Anodizing: Pure aluminum oxidizes easily and darkens. Hard anodizing forms a hard, wear-resistant, and corrosion-resistant oxide layer, enhancing cookware durability.

Non-Stick Coating (PTFE): Aluminum substrates combine well with non-stick coatings, making them ideal for non-stick pans.

Production and Processing of Cookware Aluminum Circles

The typical production process includes:

1. Casting: Melting and refining aluminum ingots, then casting into slabs.

2. Hot Rolling: Rolling the slabs to the required thickness.

3. Cold Rolling: Further rolling to ensure thickness precision and flatness.

4. Stamping or Spinning: Cutting or forming into circles.

5. Annealing: Achieving O temper or desired mechanical properties.

6. Surface Treatment: Polishing, anodizing, or coating as per customer requirements.

7. Packaging and Shipping: Standard anti-moisture and anti-scratch packaging for transport and storage.

MC Aluminum, as a professional aluminum circle manufacturer, supplies 1050 and 1060 aluminum circles with diameters from 100mm to 1200mm and thicknesses from 0.4mm to 6mm. We support surface treatments, customized packaging, and fast delivery. Our products are exported to multiple countries, highly favored overseas, with comprehensive after-sales service, ensuring reliable ordering for our customers.

Contact Us