Automotive heat insulation aluminum plate manufacturers

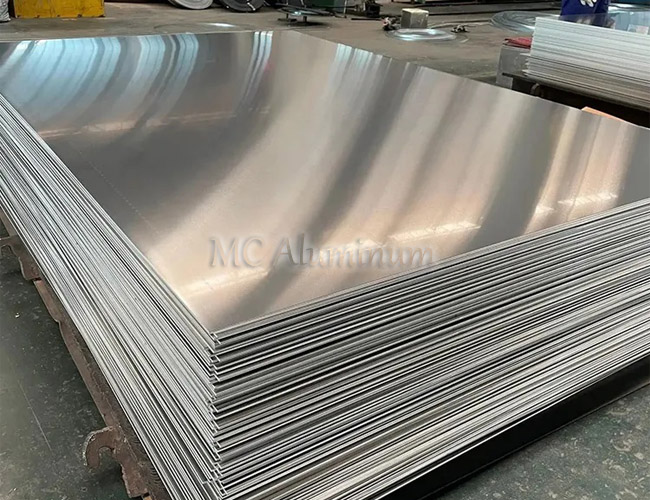

The main function of automobile heat shield is to reduce the transfer of radiant heat flow. The body heat shield is generally arranged on both sides of the engine and above the exhaust pipe channel at the bottom of the body. It mainly uses the principle of reflective heat insulation of the heat shield to cut off the transfer of heat, and it also has a certain effect of local noise insulation. The material of the insulation board is generally made of industrial pure aluminum, such as 1050 aluminum sheet, 1060 aluminum sheet.

1060 aluminum plate and 1050 aluminum plate are pure aluminum plates, with an aluminum content of 99.6%, high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment cannot be strengthened, and machinability is not good; easy to withstand various pressures Processing and extension, bending.

Aluminum plates for automotive heat shields have the following advantages:

1. Light in weight, with a density of 2.7g/cm3, about 1/3 of steel;

2. Good thermal conductivity, easy to dissipate heat;

3. Good plasticity, can be easily made into plates and foils;

4. Good corrosion resistance, easy to form dense alumina layer on the surface;

5. It has good heat resistance.

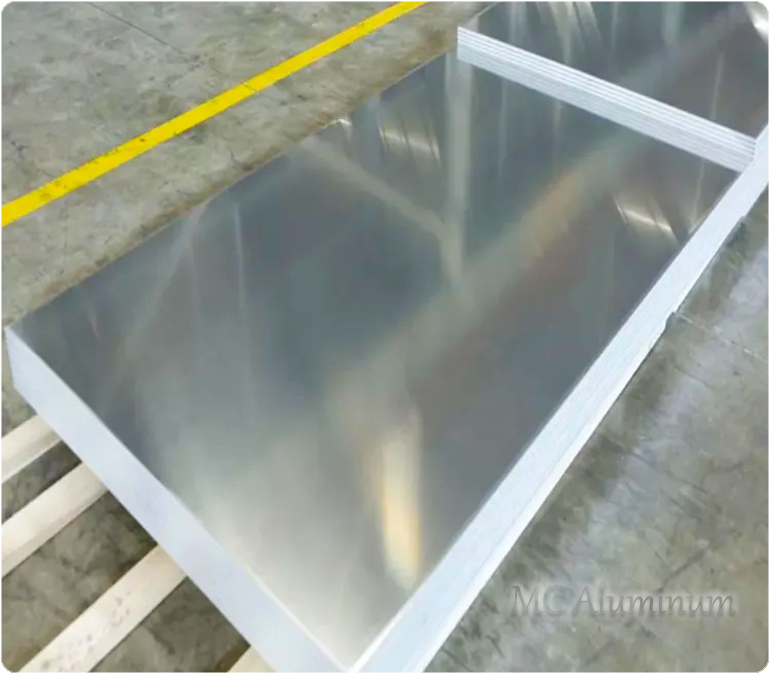

MC Aluminum specializes in the production of aluminum plates, which can produce heat-insulating aluminum plates with a thickness of 0.1-1.5mm. It specializes in providing automotive heat-insulating aluminum plates, aluminum plates for heat shields, automotive heat-insulating patterned aluminum plates, and automotive heat-insulating embossed aluminum plates. MC Aluminum has a complete range of product models, exports worldwide, has its own production line, fast delivery, and guaranteed after-sales service. Welcome new and old customers to come to order.

Contact Us