Thickness Options for 6061 Marine Aluminum Plate

In modern shipbuilding and offshore engineering, aluminum alloys are widely used due to their lightweight, high strength, and excellent corrosion resistance. Among them, 6061 marine aluminum plate stands out as a versatile material with outstanding mechanical properties and processability, commonly used in components such as boarding ladders, decks, and structural parts. Choosing the appropriate plate thickness is crucial for ensuring structural safety, cost-efficiency, and extended service life.

6061 belongs to the Al-Mg-Si series of heat-treatable aluminum alloys and is typically available in tempers such as T6, T651, and O. It offers moderate-to-high strength, good corrosion resistance, excellent weldability, and machinability-making it one of the most widely used general-purpose marine-grade aluminum plates.

MC Aluminum supplies 6061 marine-grade aluminum plates certified by classification societies such as CCS and DNV, ensuring compliance with marine construction standards.

Recommended Thickness Options and Applications for 6061 Marine Aluminum Plate

Thin Plate (1-5 mm)

Applications: Interior cladding, cabin partitions, decorative panels

Features: Lightweight, easy to bend and form; limited load-bearing; requires reinforcement in structural uses

Medium Plate (6-12 mm)

Applications: Small-to-medium hull side panels, deck coverings, porthole frames

Features: Good balance of strength and weldability; ideal for dynamic load areas

Thick Plate (15-40 mm)

Applications: Main deck load zones, bottom hull panels, propeller brackets

Features: High impact resistance; typically used in T6 or T6511 temper (yield strength ≥ 240 MPa)

Extra-Thick Plate (>50 mm)

Applications: Large ship keels, rudder bases, heavy-duty crane supports

Features: Low internal stress (achieved via T6511 stretching); prevents deformation during machining

| Alloy | 6061 |

| Tempers | O, T6, T651 |

| Thickness | 3mm - 50mm |

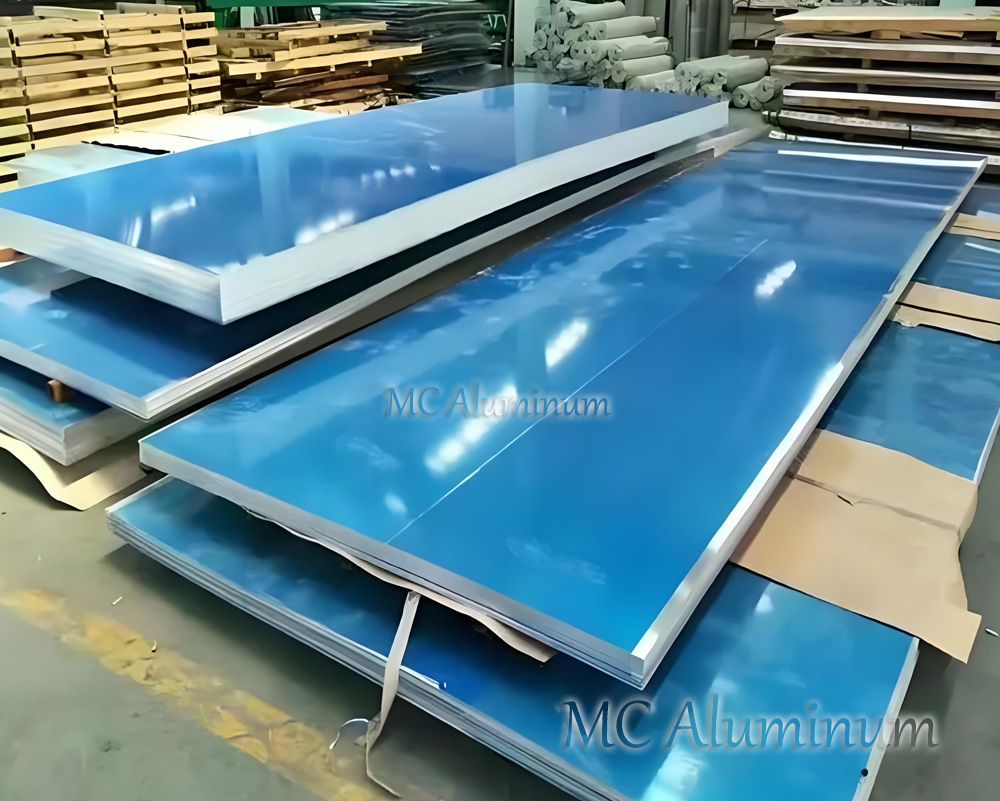

| Width | 1000mm - 2650mm |

| Length | 1000mm - 16000mm |

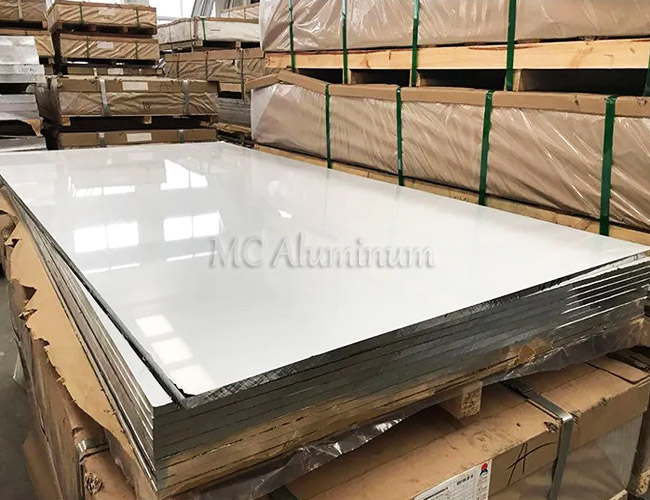

| Surface Treatment | Anodizing, coating, brushed finish, mirror finish |

| Welding Wires | ER5356 or ER4043 |

| Welding Process | TIG/MIG |

| Certification | Available with BV, DNV, CCS, and other classifications |

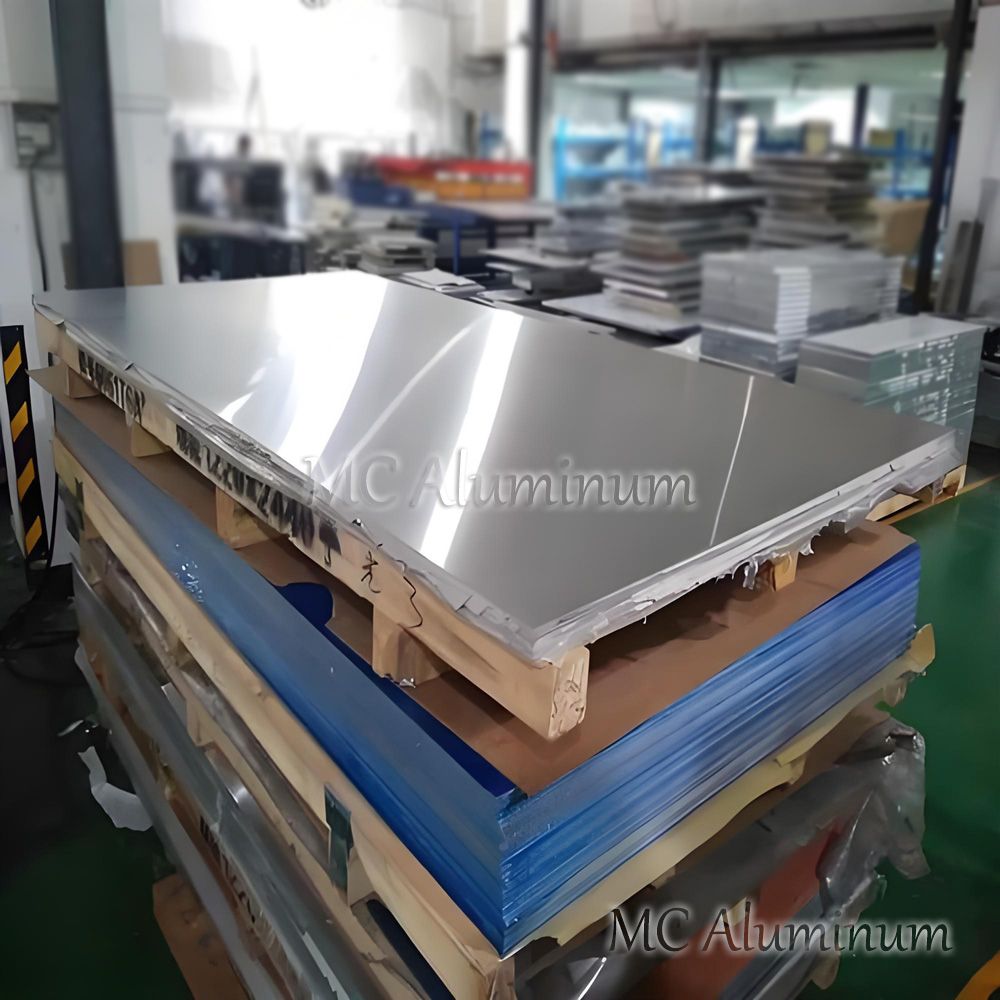

| Packaging | Standard export wooden pallets |

| MOQ | 1–3 tons |

Mechanical Properties (T6 Temper)

| Tensile Strength | ≥ 290 MPa |

| Yield Strength | ≥ 240 MPa |

| Elongation | ≥ 8% |

| Density | Approx. 2.70 g/cm³ |

Performance Features of 6061 Marine Aluminum Plate

6061 marine-grade aluminum plate is widely used in shipbuilding, floating platforms, boarding ladders, and more. Its key advantages include:

1. Corrosion Resistance: Forms a stable oxide film in marine environments, offering excellent resistance to seawater and humidity.

2. High Strength: Tensile strength ≥ 290 MPa, yield strength ≥ 240 MPa in T6 state, suitable for structural applications like hull frames and support beams.

3. Lightweight: About 1/3 the density of steel; contributes to overall weight reduction, improving speed and fuel efficiency.

4.Excellent Weldability: Compatible with multiple welding processes (MIG, TIG); strong joints and minimal deformation; easy for assembly and maintenance.

5.Good Machinability: Suitable for various processing methods; high surface quality; ideal for precision construction.

6. Versatile Surface Treatment: Can be anodized, electrophoretically coated, painted, brushed, or polished for improved durability and aesthetics.

7. Dimensional Stability: Heat-treated for high dimensional stability; ensures precise assembly and structural reliability.

8. Certifications: Approved by major classification societies (CCS, LR, ABS, DNV), meeting industry standards for marine and offshore use.

How to Choose the Right Thickness?

1.Structural Load Requirements

Critical load-bearing areas like hull beams and keel plates require thicker material to ensure safety and durability.

2.Environmental Exposure

In high-corrosion areas (e.g., prolonged seawater immersion), medium or thick plates with anodizing are recommended for enhanced durability.

3.Processing Method

Thinner plates are ideal for bending, punching, and light welding. Thicker plates require CNC cutting, drilling, and precision machining.

4.Weight & Cost Efficiency

Selecting the right thickness can ensure strength while minimizing weight and cost—crucial for fuel efficiency and overall ship performance.

Customers are advised to choose based on specific structural and application needs.

As an experienced manufacturer, MC Aluminum specializes in the production of 5- and 6-series marine aluminum alloys, including 5083, 5052, 5754, 5059, 6061, and 6082 aluminum plates. We also produce marine aluminum profiles, FSW plates, and aluminum-steel composite panels, which are widely used in various shipbuilding applications. Our products are of consistent quality and exported to numerous countries. We offer short lead times and reliable after-sales service. Order with confidence.

Contact Us