Deep drawing aluminium circles

It is processed by continuous stamping equipment and processed directly on the aluminum circle. The advantages of deep drawing are:

1. Good permeability: the excellent oily agent prevents the stamping and drawing parts from cracking and cracking.

2. Strong extreme pressure: It can effectively improve the quality and processing efficiency of the workpiece and increase the life of the mold under high, deep and difficult processing conditions.

3. High lubricity: strong adhesion, effectively lubricating workpieces and molds.

Currently it has 200mm-800mm. The stamping die can stamp and produce various aluminum rings and deep-drawn products for containers, all of which are hot-rolled series, with high elongation and good anodizing effect. This kind of aluminum ring is mainly used for various kitchen utensils, cooking utensils, containers, etc.

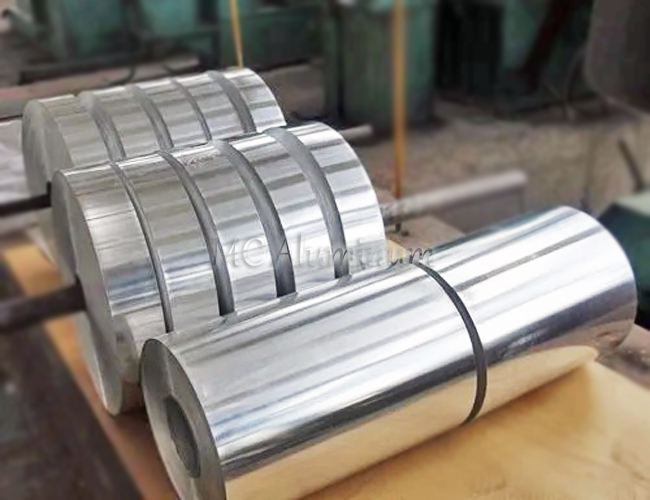

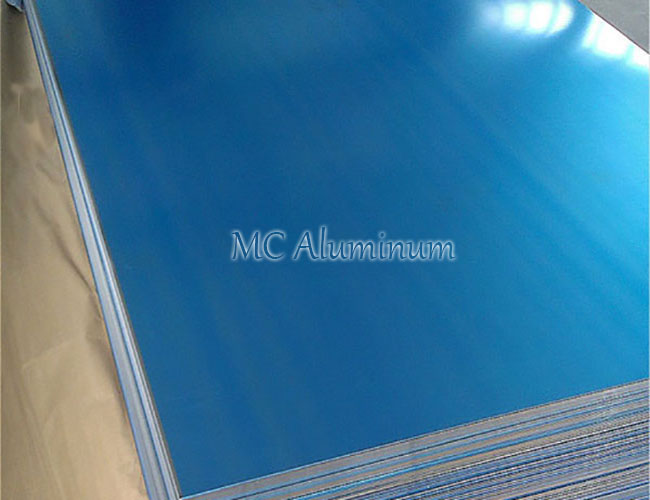

Aluminum circles specifications

| Alloy | 1060, 3003, 5052, 8011, 1050, 1070, 1100, cold rolled, hot rolled. |

| Temper | O, H12, H14, H18, H24, hard state, soft state, stretchable state. |

| Thickness | 0.3~10mm |

| Diameter | 100~1250mm |

MC Aluminum has complete product specifications and huge production capacity, specializing in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products, which can meet your individual processing needs and provide you with the latest product quotations. Looking forward to your consultation!

Contact Us