Four material selection principles for marine aluminum alloys

Aluminum alloys have been used in the shipbuilding industry for nearly a hundred years. Due to their low density, high strength, corrosion resistance and weldability, they have become an ideal choice for lightweight ships. Compared with steel or other materials, the weight of aluminum alloy ships can be reduced by 15% to 20%. Aluminum alloys can be used as plates, extruded and cast, and have higher speeds, longer life and lower processing costs. These advantages promote the widespread use of aluminum alloys in shipbuilding, and the shipbuilding industry also provides a broad market for them.

Marine aluminum alloys are used in marine ships and other fields, so they have more stringent process requirements and performance standards than other ordinary aluminum alloy products. The following are the material selection principles for marine aluminum alloys:

First, there is a high specific strength and specific modulus. The structural strength and size of the ship are closely related to the yield strength and elastic modulus of the material. Since the elastic modulus and density of aluminum alloys are roughly the same, the addition of alloying elements has little effect. Therefore, increasing the yield strength within a certain range is effective in reducing the structure of the ship. It is usually difficult for high-strength aluminum alloys to have both excellent corrosion resistance and weldability. Therefore, marine aluminum alloys are generally medium-strength, corrosion-resistant and weldable alloys.

Second, excellent welding performance. At present, the main method used in ships is automatic argon arc welding. Good weldability means that the tendency of cracks formed by aluminum alloys during welding should be small, that is, aluminum alloys should have good welding crack resistance. Because under shipbuilding conditions, the lost welding performance cannot be restored by reheat treatment.

Third, excellent corrosion resistance. Ship structures are used in harsh seawater media and marine environments. Therefore, corrosion resistance is one of the main characteristics of marine alloys.

Fourth, aluminum alloys have good cold and hot forming properties. Because shipbuilding requires multiple cold processing (such as folding, curling, roll bending, stamping, etc.) and hot processing (such as hot bending, pyrotechnic correction, etc.), marine aluminum alloys must be easy to process and form, without crack defects, and can still meet strength and corrosion resistance requirements after processing.

Advantages of marine-grade aluminum alloys for ships:

1. Reduce ship weight: Low specific gravity can reduce ship weight, reduce engine capacity, increase speed, reduce fuel consumption, and save fuel.

2. Improve stability: Improve the length-to-width ratio of the ship, increase stability and maneuverability, and increase load capacity to obtain additional profits.

3. Corrosion resistance: Good corrosion resistance can reduce maintenance costs and extend service life (usually more than 20 years).

4. Processing performance: Easy to cut, stamp, cold bend and other processing, suitable for hull streamlining, and can reduce the number of welds.

5. Welding performance: It has good welding performance and is easy to operate.

6. Safety: Small elastic modulus, can effectively absorb impact stress and enhance safety.

7. Recyclability: Aluminum waste is easy to recycle and meets environmental protection requirements.

8. Low temperature adaptability: No low temperature brittleness, suitable for making low temperature equipment.

9. Non-magnetic: Does not affect the compass, suitable for minesweepers to avoid mine attacks.

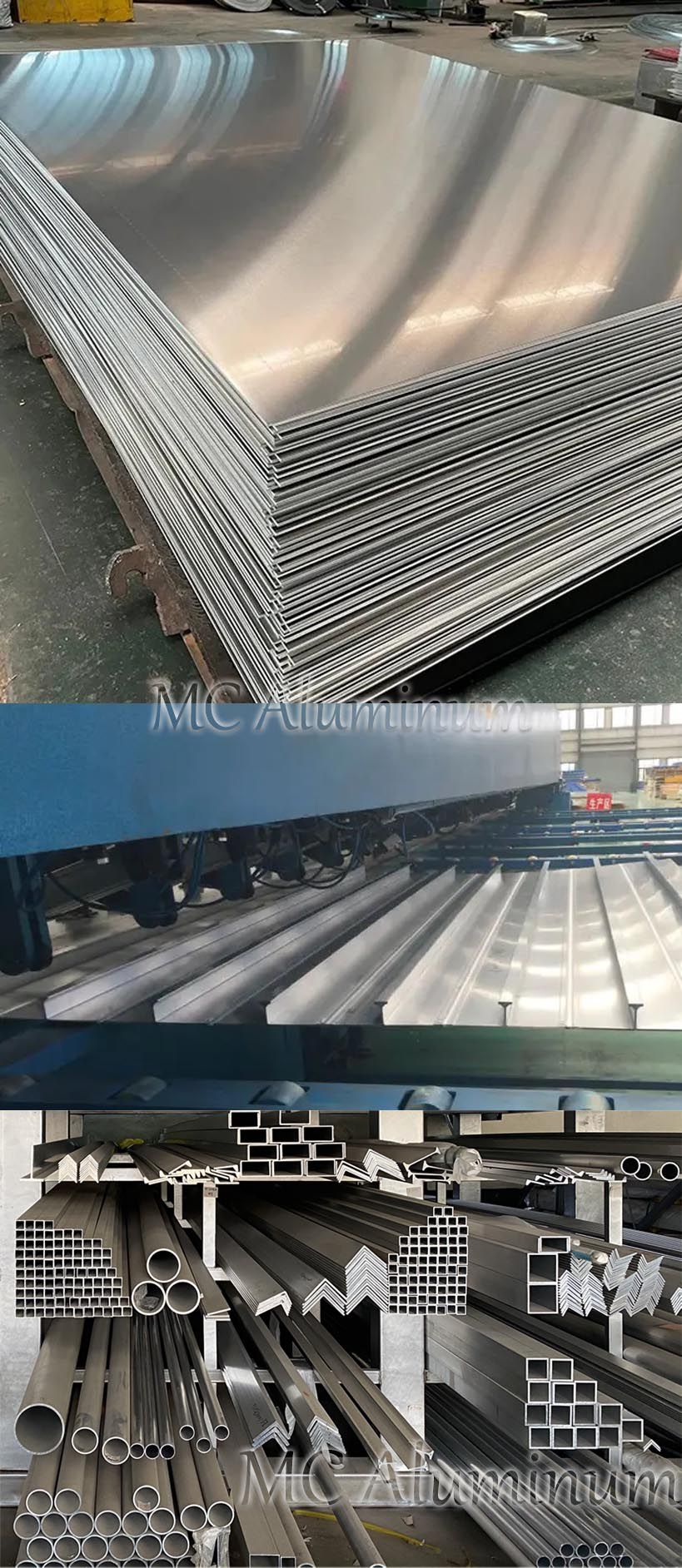

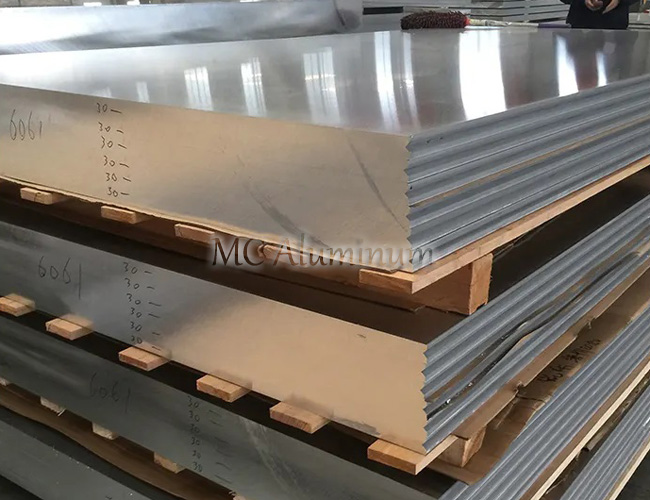

The selection of marine aluminum alloys is relatively strict. Currently, 5083, 5086, 5454, 5754, 6061 and other aluminum alloy products are mostly used. As a professional marine aluminum plate manufacturer, MC Aluminum's aluminum plates, extruded aluminum profiles, and FSW ribbed plates used in shipbuilding are all certified by classification societies. The product models are complete, the quality is stable, and they are exported to many countries and regions overseas. The prices are low and the after-sales service is guaranteed.

Contact Us