Performance advantages of hot-rolled aluminum sheet

Hot rolling generally refers to rolling performed above the metal recrystallization temperature. During hot rolling, the deformed metal undergoes hardening and softening processes at the same time. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, the metal will produce a certain amount of work hardening as the degree of deformation increases. However, in the hot rolling temperature range, the softening process plays a leading role. Therefore, at the end of hot rolling, the recrystallization of the metal is usually incomplete, and the aluminum alloy plate and strip after hot rolling presents a microstructure state in which recrystallization and deformation structure coexist.

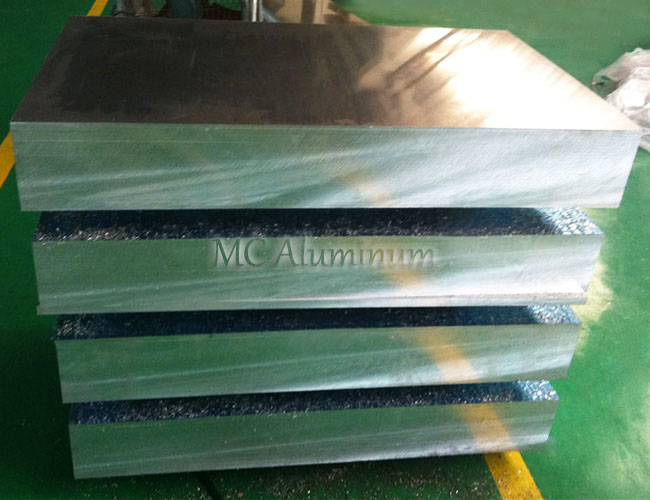

Compared with ordinary cast-rolled products, hot-rolled aluminum sheets have the characteristics of good surface quality, strong mechanical properties and ductility, and good oxidation effect. The hot-rolled aluminum sheet produced by MC Aluminum not only has a smoother and more delicate surface, good deep drawing and oxidation effects, and the finished product width is as high as 2650mm. Hot-rolled aluminum sheets are widely used in wide curtain wall panels, automobiles, ships, busbars, silos, stamping parts, molds and other fields.

Performance advantages of hot-rolled aluminum sheets produced by MC Aluminum:

1. Hot rolling can significantly reduce energy consumption, good plastic processing, low deformation resistance, no obvious work hardening, easy rolling, and reduced energy consumption required for metal deformation.

2. Hot rolling usually uses large ingots and large reductions for rolling. The production rhythm is fast and the output is large, which creates conditions for large-scale production.

3. Hot rolling can effectively improve the processing performance of metals and alloys, that is, the coarse grains in the casting state are broken, the micro-cracks are healed, the casting defects are reduced or eliminated, the as-cast structure is transformed into a deformed structure, and the processing performance of the metal is improved.

4. The as-cast structure is transformed into a processed structure by hot rolling, and the plasticity of the material is greatly improved through the transformation of the structure.

5. The characteristics of the rolling method determine that there is anisotropy in the properties of the rolled plate. First, there are obvious performance differences in the longitudinal, transverse and high directions of the material. Second, there are deformation textures and recrystallization textures. There is an obvious directionality in control performance.

MC Aluminum specializes in the production of hot-rolled aluminum sheets. The alloy numbers include 1 series, 3 series, 5 series, 6 series, 8 series, etc. The product models are complete and can be customized to meet the various needs of customers. The company has large output, fast delivery, global export, and after-sales guarantee.

Contact Us