Aluminum alloy bottle cap material

Bottle caps can be seen everywhere in daily life. The material of bottle caps can be divided into plastic and aluminum alloy. Compared with plastic materials, aluminum alloy has the advantages of environmental protection, recyclability, no pollution, and low price. Aluminum alloy bottle cap material not only has good deep drawing performance and low anisotropy, but also has a certain baking strength after multiple color printing and curing. The aluminum alloy used for bottle cap materials is widely used in Aluminum for cosmetic bottle caps, aluminum for pop can bottle caps, aluminum for wine caps, aluminum for medical bottle caps, etc.

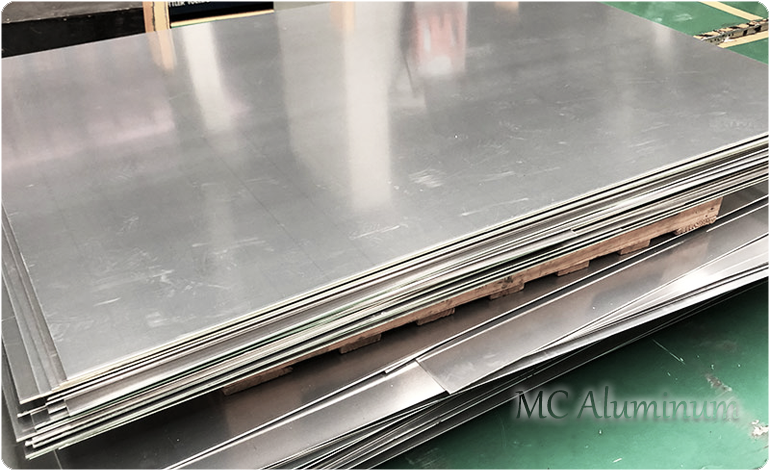

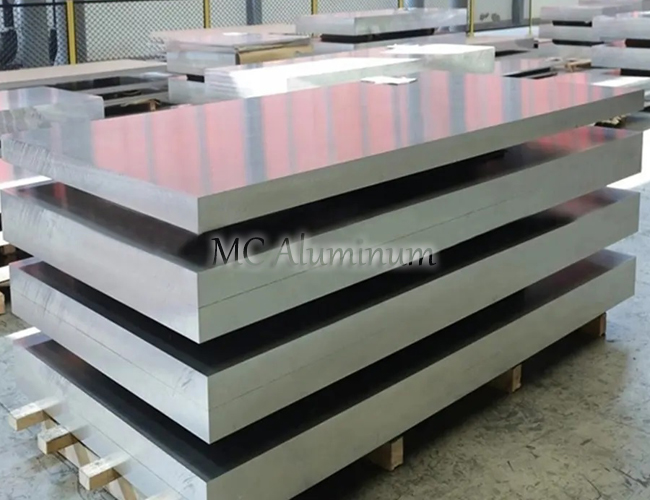

The aluminum sheet for aluminum alloy bottle cap material can use 1 series, 3 series, 5 series, 8 series finished aluminum coil as raw material, including 8011, 3105, 1060, 3104, 5052, etc.

Specifications of aluminum plate for bottle cap material:

Alloy number: 8011, 3105, 1060, 3104, 5052

Temper: H14, H16, H18

Thickness: 0.15-05mm

Width: 200-1500mm

Thickness tolerance: ±0.005mm

Width tolerance: ±1mm.

Application fields of aluminum alloy bottle cap materials:

Pharmaceutical bottle caps are usually made of 8011 aluminum foil, which has good sealing performance and is mainly used for closing ports of infusion bottles and oral liquid bottles.

The caps of cans are usually made of 5052 aluminum plate, the hardness is slightly better than other alloys, so as to avoid extrusion deformation during transportation and ensure the aesthetic appearance.

The cosmetic bottle cap is made of 3105 aluminum plate, which has good formability and exquisite appearance.

Why is the bottle cap material made of aluminum alloy?

Aluminum bottle cap materials are widely used in product packaging, because aluminum has good oxidation resistance, forming a dense oxide film on the surface of aluminum, which protects the original physical properties of the product and has good sealing performance. It ensures that the product does not come into contact with the outside world.

The aluminum PP cover has simple structure, strong adaptability and good sealing effect. Not only the printing effect is good, but also it is easy to realize mass production and the cost is low.

MC Aluminum specializes in the production of aluminum plates for bottle cap materials. The surface of the product plate is flat, the oil is clean, and there is no black silk mark. The product models are complete and can be customized according to customer needs. They are exported globally and provide raw materials for many foreign bottle cap manufacturers. High market recognition.

Contact Us