8011 8021 1235 8079 O Aluminum foil for food soft packaging

Soft packaging aluminum foil mainly uses the metallic luster, light-proof, air-proof and certain strength and ductility of aluminum foil. Therefore, aluminum foil for food soft packaging is widely used in the packaging of various foods, such as dairy products, juice, meat, fish, coffee, chocolate and other perishable foods. It can maintain the freshness of food, extend the shelf life, maintain nutrients, and avoid pollution and deterioration.

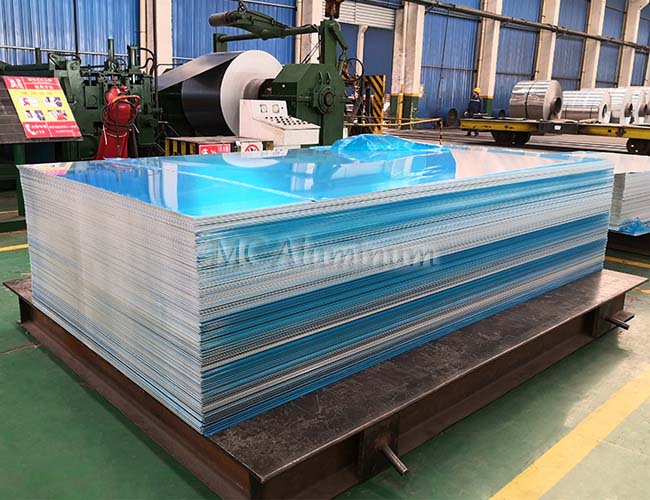

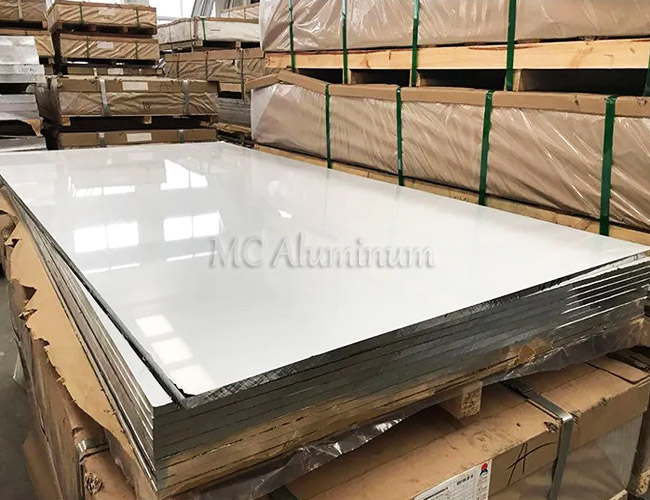

Food grade aluminum foil is completely opaque to visible light, non-toxic and pollution-free, clean and oil-free on the surface, and the composition of aluminum foil meets the requirements of food packaging standards. At present, soft packaging foil mainly uses 1235, 8011, 8021, 8079 and other alloys, and the thickness is usually 0.02mm, 0.015mm, 0.009mm, 0.007mm, etc.

The overall production process of aluminum foil for soft packaging is: aluminum ingot smelting - casting and rolling - cold rolling - intermediate annealing - cold rolling - aluminum foil raw material - rough rolling - intermediate rolling - finishing rolling (double-combination) - slitting - finished product annealing - packaging.

Food grade packaging aluminum foil specifications:

| Alloy | 1235, 8011, 8021, 8079 |

| Temper | O |

| Thickness | 0.006-0.15mm |

| Width | 100-1600mm |

| Length | 100-16000mm |

| ID | 76/152mm |

| OD | 400-850mm |

| Core | (3" or 6") iron core/aluminum core |

| Product features | low pinhole, high elongation |

| Water-brushability | Grade A |

| Surface | rolled smooth foil, single-sided smooth |

| MOQ | 1-3 TONS |

| Delivery cycle | 25~35 days after receiving the deposit |

| Packaging | Fumigation wooden box suitable for long-distance sea transportation |

1235 Advantages of 8011 aluminum foil for flexible packaging:

1. High barrier properties

2. Light blocking properties

3. High and low temperature resistance

4. Corrosion resistance

5. Beautiful appearance

6. Green, environmentally friendly and recyclable

7. Non-toxic and odorless, safe and hygienic

Flexible packaging foil performance requirements:

1. Flat plate shape (less than 20Ⅰ)

2. Consistent thickness (3% tolerance)

3. Good elongation (less than three meters)

4. Requires a flat and clean surface, no oil stains, roller eyes, roller marks, and few pinholes

5. Fewer pinholes;

6. Appropriate mechanical properties

Contact Us