1050 aluminum sheet,1060 aluminum sheet,1070 aluminum sheet for PS plate substrate

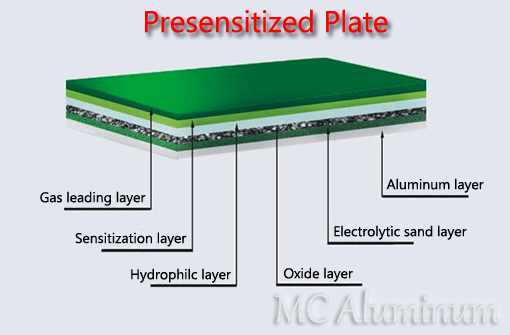

The PS version is also called the pre-coated photosensitive version, which refers to the aluminum plate used for printing. PS is through the hot and cold rolling process, the manufacturer pre-coats the photosensitive resin layer on the aluminum plate, etc., and after drying, it is made into a printing plate for various purposes. The PS plate is composed of a photosensitive layer and a supporting aluminum substrate or plate base. At present, the most commonly used is the aluminum plate, usually using 1050 aluminum plate, 1060 aluminum plate, 1070 aluminum plate, etc., and the photosensitive layer is to apply the photosensitive liquid on the layer formed on the substrate. Since the annual consumption of the PS version is very high, the number of aluminum plates required is also high. The aluminum plate is not only its important support, but also plays an important role in the performance of the PS version.

1050 aluminum plate, 1060 aluminum plate, and 1070 aluminum plate belong to the 1 series pure aluminum, which has the advantages of low density, high strength, easy processing, corrosion resistance, good hydrophilicity, good electrical and thermal conductivity, and good surface treatment. Processing requirements (stamping, stretching), it has become a commonly used PS plate substrate.

Technical parameter

| Alloy | 1050,1060,1070 |

| Temper | h18 |

| Thickness | 0.10-0.50mm |

| Width | 400-1600mm |

| Length | C |

There are two types of PS: positive PS and negative PS. Among them, the positive PS plate occupies a large share and is used in most of the medium and large printing tasks. Its manufacturing technology is becoming more and more mature.

The commonly used photosensitizer for the positive PS version is a soluble diazohydroquinone photosensitive resin, and the commonly used photosensitizer for the negative PS version is an insoluble azide-based photosensitive resin.

The positive PS version has the advantages of light weight, stable performance, clear image, rich layers and high printing quality. Its invention and application is a major change in the printing industry. At present, the PS plate has been matched with electronic typesetting, electronic color separation, and multi-color offset printing, and has become the mainstream plate-making system today.

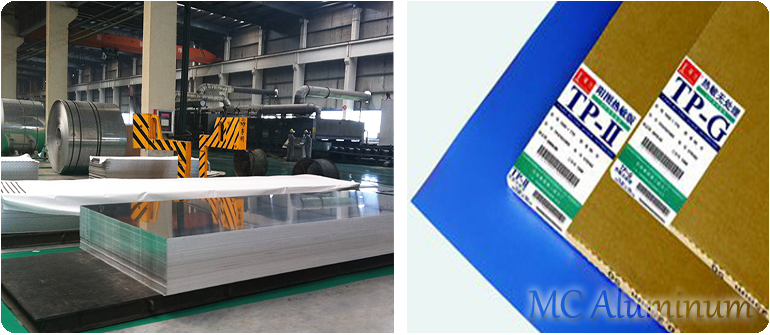

MC Aluminum adopts advanced equipment and technology to avoid defects such as hard scratches, flat marks, shock marks, etc., to ensure that the quality of the aluminum plate is excellent and meets the requirements of aluminum for printing. MC Aluminum has complete product specifications and huge production capacity to meet your individual processing needs. MC Aluminum can provide you with the latest product quotations. Looking forward to your consultation!

Contact Us