Aluminum circles for pans

Aluminum alloy is the most commonly used cookware material in the world because of its light weight, fast heat conduction and easy processing and shaping. Most of all types of non-stick pans also use aluminum alloy as the base material. Aluminum discs are used to make kitchen utensils, and the use of new materials has become very mature. 1050, 1060, 1100 and 3003 aluminum circles, etc., which have better electrical conductivity, thermal conductivity and heat resistance, are widely used in the production of aluminum pots and pans around the world.

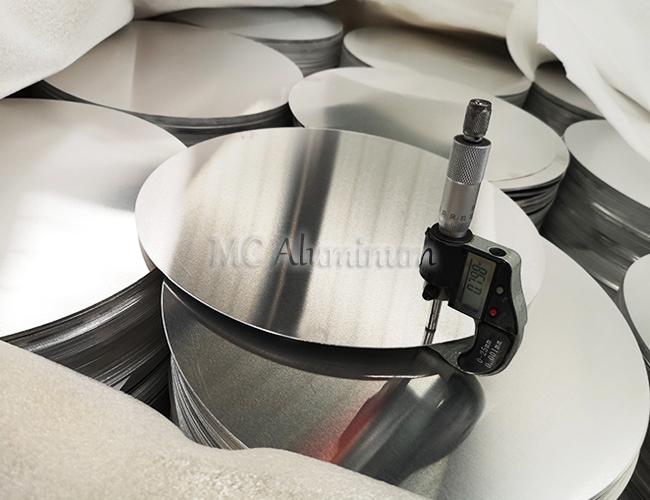

Specifications of aluminum discs for pans:

| Alloy | 1100, 1050, 1060, 1070, 3003, 5052, 5754, etc |

| Temper | O, H12, H14, H22, H24 |

| Thickness | 0.3-10mm |

| Diameter | 20-1300mm |

| Type | disc, round, disk |

| Surface | rolled surface |

| Delivery time | 30~35 days after receiving deposit |

| Packing | wooden pallets suitable for long-distance shipping |

| Sample | 1~3 pieces |

| Shipping port | any port in China |

| Price terms | EXW, FOB, CIF, CFR, CNF, etc. |

| Payment method | L/C, wire transfer, Western Union, etc. |

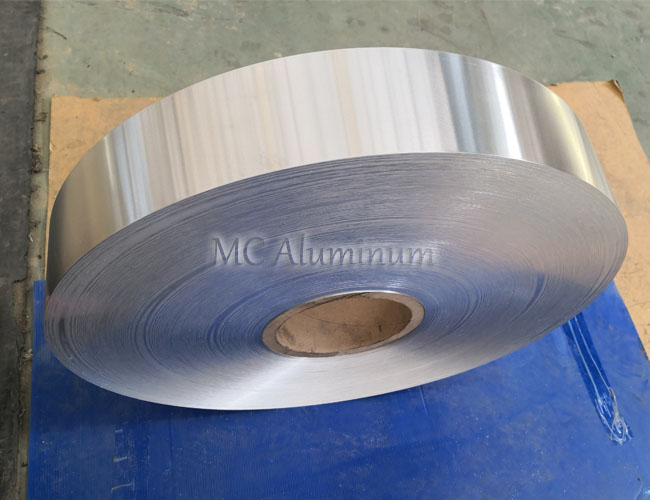

Production process of aluminum discs for pans:

Casting ingot/master alloy—smelting furnace—holding furnace—DC continuous caster—slab—gold stripping machine—hot rolling mill—cold rolling mill—punching—annealing furnace—final inspection—packaging—delivery

Pan aluminum circle performance:

1. Excellent elongation and tensile strength;

2. Good processing performance, high stamping and stretch forming performance;

3. Gas welding, hydrogen welding, resistance welding, and brazing;

4. High plasticity, electrical conductivity and thermal conductivity;

5. Easy to perform various pressure processing, extension and bending;

As a large-scale aluminum circle manufacturer, MC Aluminum relies on advanced technology, rich production experience, and high-quality product quality to provide customers with aluminum discs at favorable prices, complete models, and precise dimensions.

Contact Us