Aluminum Slug Manufacturing Process - MC Aluminum

What is an Aluminum Slug?

An aluminum slug refers to a solid piece of metal primarily made from aluminum or aluminum alloys, produced through processes such as smelting and casting. It is commonly used for further processing and manufacturing. Aluminum slugs can serve as intermediate raw materials or be sold as products to other industrial users.

Common Types of Aluminum Slugs

Pure Aluminum Slug:

Aluminum content ≥99.0% (e.g., industrial pure aluminum 1060, 1070). These slugs have good ductility but relatively low strength, making them suitable for applications requiring electrical or thermal conductivity.Aluminum Alloy Slug:

Elements like copper, magnesium, and zinc are added (e.g., 6061, 7075 alloys). Strength and corrosion resistance are enhanced through solution treatment and aging processes, making them ideal for machining.Wrought Aluminum Slug:

Processed through rolling or extrusion (e.g., 6061-T6 aluminum alloy). These slugs have a dense microstructure and high strength, often used in structural components.

Core Processes and Key Technologies in Aluminum Slug Manufacturing

1. Raw Material Preparation & Alloy Selection

Alloy Types:

Common aluminum alloys include 8011, 3003, etc. Composition and condition (e.g., H14, H16) are adjusted based on end-use requirements to meet strength and ductility needs.

Billet Production:

Aluminum ingots are processed into billets using hot rolling or continuous casting and rolling. Continuous casting and rolling is preferred due to better grain uniformity.

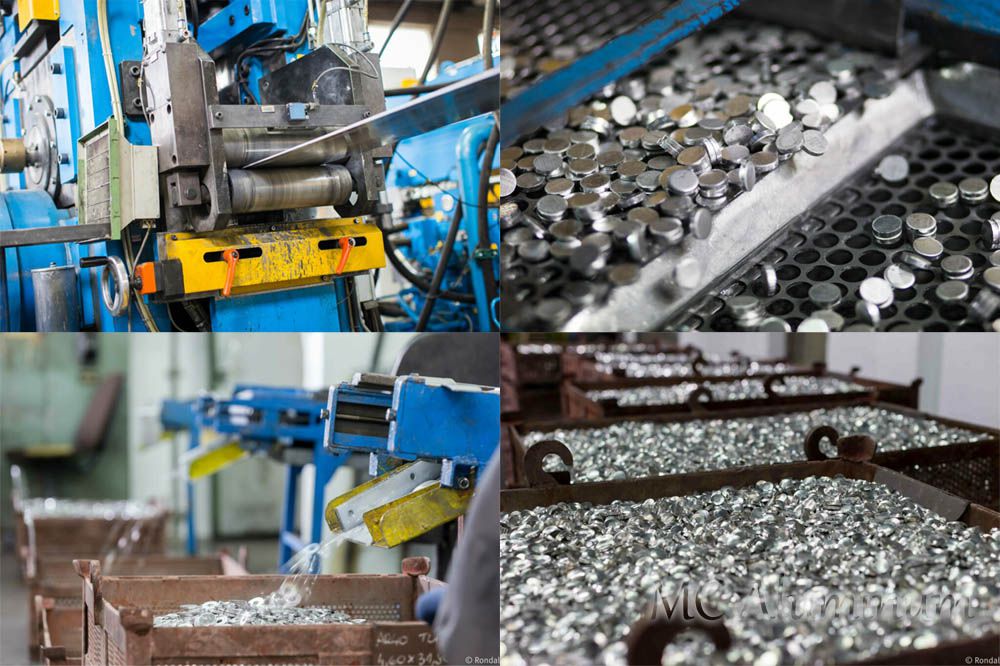

2. Plastic Forming Processes

Hot Rolling / Cold Rolling:

Hot rolling is used to initially reduce the thickness of aluminum ingots into large-size slabs. Cold rolling further refines the thickness (e.g., 0.20–0.23mm) and improves surface smoothness.

Post-rolling quality must be ensured — no roll marks, scratches, or stains to avoid downstream defects.

Stamping and Drawing:

Precision stamping is performed with multi-station molds, often combined with drawing processes to form aluminum into slug shapes or can ends.

Fully automated production lines can produce thousands of pieces per minute, completing edge curling, thread rolling, and other structural formations simultaneously.

3. Surface Treatment and Functional Enhancement

Hydrophobic Coating Technology:

Inspired by lotus leaf microstructures (e.g., TOYAL LOTUS technology), ultra-fine surface textures create air layers that reduce liquid adhesion.

Corrosion Resistance and Print Compatibility:

Surface pretreatments (e.g., anodizing) enhance corrosion resistance and cleanliness, ensuring high-precision printing compatibility.

4. Quality Inspection & Packaging

Defect Detection:

Automated vision systems inspect for dimensional deviations, surface defects, and sealing integrity, ensuring high product pass rates.

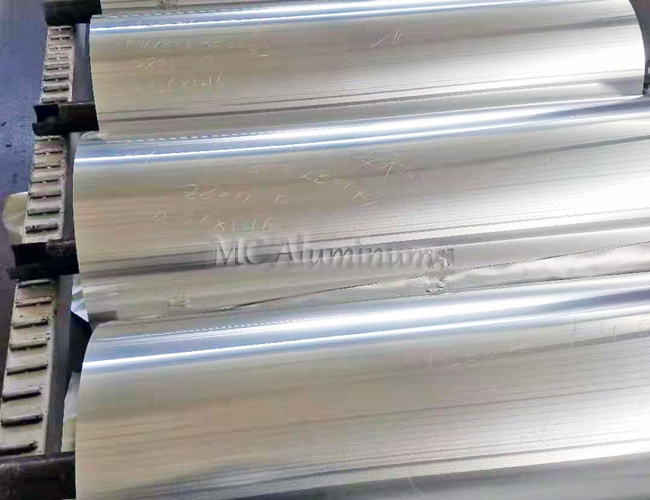

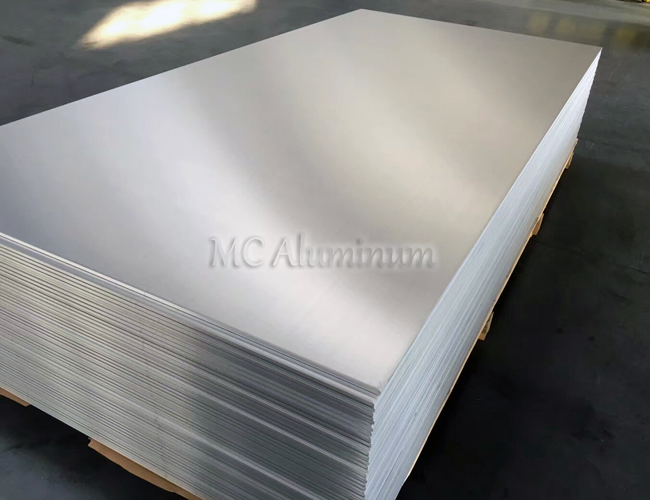

Packaging & Transport:

Finished slugs or semi-finished sheets are stacked using paper cores or rolled, tailored for downstream processing needs.

5. Environmental Protection & Cost Control

Recycling:

Scrap produced during aluminum slug manufacturing can be remelted and reused, reducing resource consumption.

Process Optimization:

Continuous casting and rolling reduce energy consumption. Enhancing mold precision during stamping reduces material waste.

This integrated process shows that aluminum slug manufacturing requires synergy among material science, forming technology, and surface engineering.

We provide pure aluminum / aluminum alloy slugs based on your specific needs and requirements:

| Alloys & Treatments | |

| Alloys | 1050, 1060, 1070, 3102, 3003, 5052, 6061, 6082, etc. |

| Heat Treatment | OH – soft annealed |

| H18 – hard | |

| Dimensions & Shapes | |

| Diameter | 5-14mm |

| Thickness | 1.5-15mm |

| Shapes | flat, domed, round, oval, rectangular, etc., with or without holes |

Contact Us