Automobile water cooling plate uses 3 series aluminum alloy

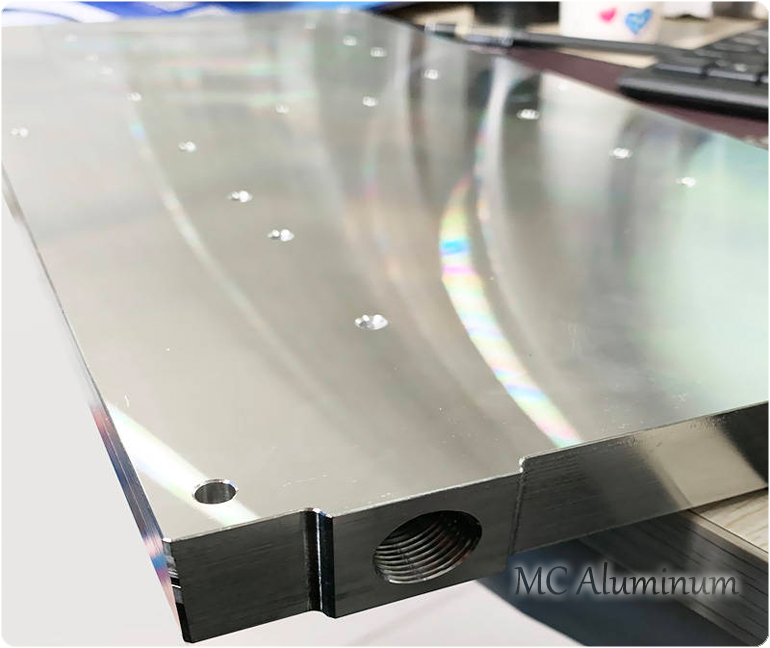

What is a water cooling plate? In the power battery system, the battery generates excess heat when working. The heat is transferred through the surface contact between the battery or module and the plate-shaped aluminum device, and is eventually taken away by the coolant passing through the internal flow channel of the device. This plate-shaped aluminum device is a water-cooled plate.

Water-cooled plates are an important part of the thermal management system of new energy vehicles and are usually used in load-bearing and corrosion-resistant environments. Therefore, when selecting the manufacturing material of the water-cooled plate, the strength and corrosion resistance of the material need to be considered. Automobile water-cooling plates generally use aluminum brazing composite materials, and the process mainly includes raw material stamping-cleaning-flux coating-riveting-brazing-testing-sealing and other processes. In order to ensure the stamping and stretching requirements of water-cooled plates, the materials used are required to have good tensile capabilities.

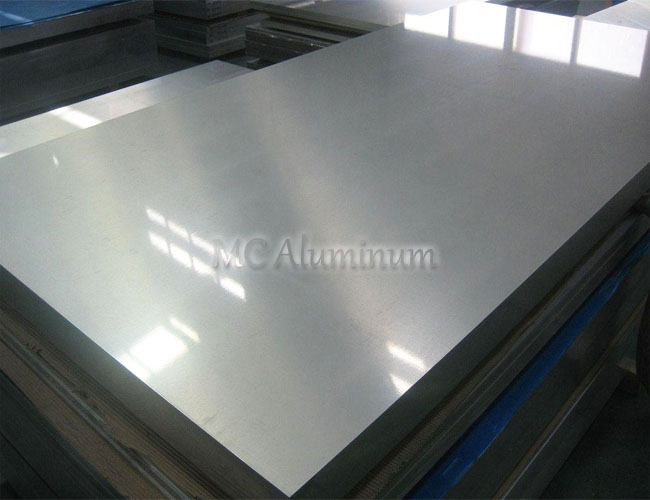

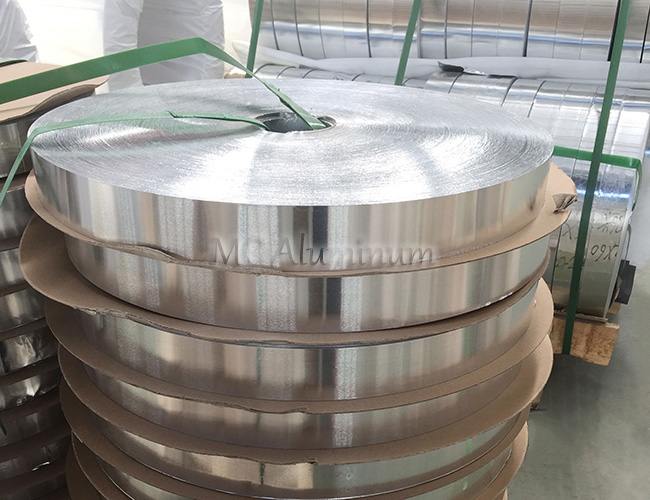

With the rapid development of the new energy vehicle industry, the demand for power battery packs is growing rapidly, and the demand for production capacity of water-cooled plates, a key component of the battery pack, is also increasing. The market demand for 3003 aluminum plates for brazing composite materials will also continue to rise. The main alloying element of 3003 aluminum plate is manganese. The strength of 3003 aluminum plate alloy increases with the increase of manganese content. 3003 aluminum plate is a material with good formability, good corrosion resistance and weldability.

Advantages of using 3xxx series aluminum alloy for automotive water-cooling plates

1. Light weight: Aluminum alloy has the advantages of low density, high specific strength, and easy processing and forming. It is currently an ideal lightweight material for automobiles.

2. Easy to process: It has good welding performance and is easy to process and shape.

3. Good consistency: stable performance, high elongation, easy stamping, and strong welding performance.

4. Excellent corrosion resistance: 3003 aluminum plate belongs to the aluminum-manganese alloy series, also known as anti-rust aluminum plate. It still has good anti-rust ability in humid environment.

5. Good stamping and tensile properties: 3003-O aluminum plate is soft, has high plasticity, is easy to punch and stretch, and meets conventional processing requirements.

6. Recyclable: Aluminum alloy materials have a high recyclability rate and are green and environmentally friendly.

MC Aluminum is a professional aluminum plate manufacturer specializing in the production of 3003 aluminum plate base materials for automotive water-cooling panels. It is a raw material supplier for domestic and foreign new energy vehicle manufacturers. The product plate shape is smooth, clean with oil removal, no black wire, and no marks. , cutting without deformation, no burrs and other advantages, the products are exported to many overseas countries and regions, sample mailing services can be provided, and after-sales service is perfect, users can order with confidence!

Contact Us