Tank truck aluminum plate manufacturer

The length of aluminum plates commonly used in tank trucks on the market is generally within 12.5 meters, the width is less than 2.2 meters, and the thickness is generally 5, 6, 7, or 8 mm. A complete tank truck body generally requires 4-6 aluminum plates to be welded, of which the most important The can body is made of 5083H111 aluminum plate, and the lids on both sides are made of 5083-O-state aluminum plates. The O-state is softer, and the lid needs to be bent, and the partition part is also made of 5083-O-state. In addition, some manufacturers use 5454H111 aluminum plates to produce tanks.

The aluminum plates suitable for tank truck bodies are mainly 5 series and 6 series related products. The 5 series is an aluminum alloy with magnesium as the main alloying element. The 6 series is an aluminum alloy with magnesium and silicon as the main alloying elements and the Mg 2Si phase as the strengthening phase. The main alloy grades include: 5052 aluminum plate, 5083 aluminum plate, 5754 aluminum plate , 6061 aluminum plate and 6082 aluminum plate.

Performance of tank truck aluminum plate:

5052 aluminum plate is an AL-Mg alloy aluminum plate. It is the most widely used anti-rust aluminum with high strength and corrosion resistance. However, it cannot be strengthened by heat treatment. It has good plasticity during semi-cold work hardening. It has low plasticity during cold work hardening and can be polished.

The magnesium alloy in 5083 aluminum plate has high strength, and the heat-treated alloy has good processability, corrosion resistance and welding performance. It is widely used in transportation vehicles, such as ships, aircraft, vehicles and pressure vessels (liquid tank trucks, refrigerated trucks, refrigerated containers), etc.

5754 aluminum plate has the characteristics of medium strength, good corrosion resistance, weldability and easy processing and forming. It is a typical alloy among Al-Mg alloys. Abroad, 5754 aluminum alloy plates in different heat treatment states are the main materials used in the automobile manufacturing industry (car doors, molds, seals) and canning industry.

6061 aluminum plate has medium strength, good corrosion resistance, weldability, good processability, and can be anodized and colored. Because it contains a small amount of Cu, its strength is higher than that of 6063, and its quenching sensitivity is also higher than that of 6063. Air quenching cannot be achieved after extrusion, and it requires re-solution treatment and quenching aging.

6082 aluminum plate is an aluminum alloy plate that can be heat treated and strengthened. It has medium strength, good welding performance and corrosion resistance. It is mainly used in the transportation and structural engineering industries.

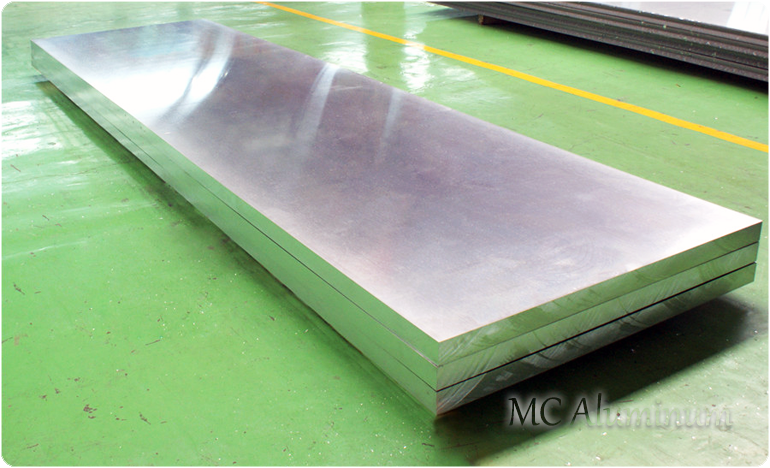

MC Aluminum is a professional aluminum plate manufacturer, specializing in the production of 1-8 series aluminum plates, with complete product models and alloy status, flat plate shape, no oil stains, no marks, no deformation when cutting, no burrs, etc. For export overseas, sample mailing services can be provided, so users can order with confidence.

Contact Us