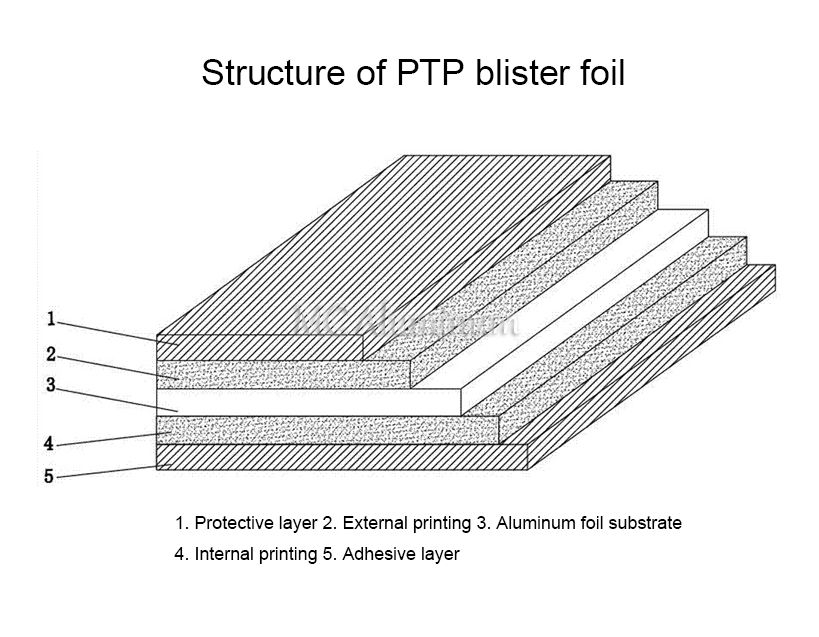

Structure of ptp blister aluminum foil

The covering materials for blisters are basically aluminum foil, mainly 8011 aluminum foil. One of the main raw materials for producing PTP aluminum foil is industrial hard pure aluminum foil, which has excellent conductivity and light-shielding properties, extremely high moisture resistance, gas barrier and taste retention, can protect the packaged objects, and is easy to puncture, making it convenient to take medicine. When used as a pharmaceutical packaging material, aluminum foil is the only metal material in the packaging material.

PTP production process:

Printing, coating protective agent and adhesive on an aluminum substrate with a thickness of 15~30μm or a thickness of 15~60um and a width of 400~800mm, and then drying and curing, longitudinal cutting, rewinding and packaging are formed to form a PTP aluminum foil finished product.

Structure of ptp blister foil:

1.Protective layer (OP): Located on the outermost layer, it protects the internal structure and prevents the external environment from damaging the internal materials.

2. Printing layer: Located after the protective layer, it can be printed and used to identify product information, such as brand, model, instructions for use, etc.

3. Aluminum foil layer (AL): This is the core material of the blister foil, mainly made of aluminum, with good barrier properties and mechanical strength, and can effectively protect the products in the package from the external environment.

4. Adhesive layer (VC): Located after the aluminum foil layer, it is used to bond the blister foil to other materials to form a sealed packaging structure.

The structure of aluminum foil for blister packaging (PTP) is generally expressed as OP/AL/VC.

Aluminum foil (PTP) for blister packaging

| Variety | A | B | C | D | E |

| 1 | Protective layer | External printing | Aluminum foil | Internal printing | Adhesive layer |

| 2 | Protective layer | - | Aluminum foil | Internal printing | Adhesive layer |

| 3 | Protective layer | External printing | Aluminum foil | - | Adhesive layer |

| 4 | Protective layer | - | Aluminum foil | - | Adhesive layer |

Introduction to medical aluminum foil:

The main component of the protective layer (OP) is acetic acid resin, which is mainly used to make the surface of PTP aluminum foil bright and smooth, fill the small gaps on the surface of PTP aluminum foil; improve the acid and alkali corrosion resistance of PTP aluminum foil, extend the shelf life of drugs; protect the printing layer to prevent ink from falling off. The coating amount of OP protective agent is generally 1±0.5g/m2.

The main component of the adhesive layer (VC) is vinyl or polyurethane hot melt adhesive, which is mainly used to heat seal well with PVC or PVDC plastic hard sheets. The coating amount of VC is generally 3.5~9±0.5g/m2, and the coating amount varies according to the heat sealing performance required by the customer.

PTP aluminum foil is mainly made of 8011 aluminum alloy with a slightly higher recrystallization temperature, H18 state, thickness of 0.02-0.025mm, the larger the bubble, the thicker the aluminum foil, even up to 0.030mm; pinholes with a diameter greater than 0.3mm are not allowed, and the number of pinholes with a diameter less than 0.3mm does not exceed 3/m2; the tensile strength is not less than 150MPa; the surface wetting tension is not less than 33×10-3N/m; the rupture strength is not less than 98KPa.

Contact Us