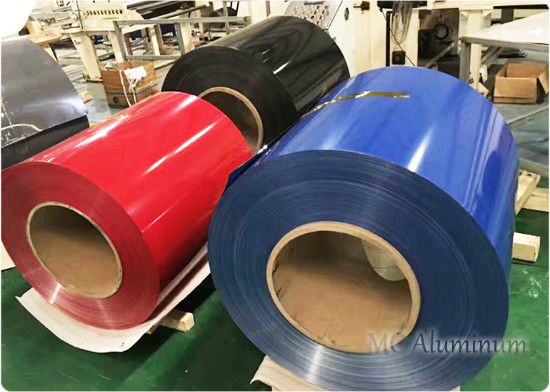

What is a painted aluminum coil

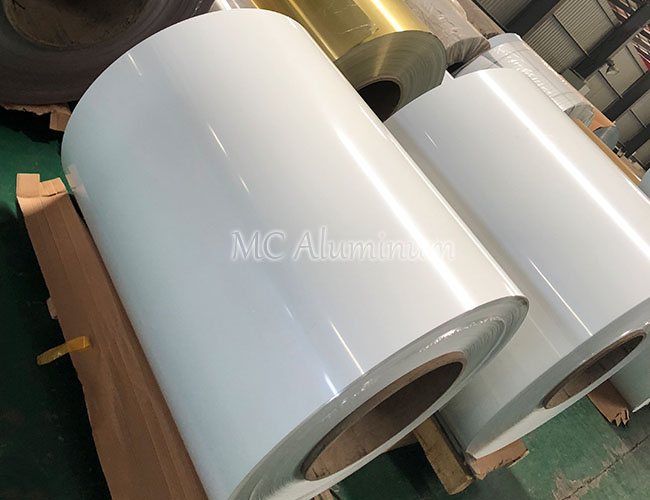

Color-coated aluminum coil refers to the product that the aluminum coil is coated with paints of various colors on the surface of the aluminum coil after cleaning, chrome plating, rolling coating, baking and other processes. Because of its good flatness, corrosion resistance, decorative and mechanical properties, it is widely used in aluminum-plastic panels, industrial factory building walls, aluminum louvers, composite panels, aluminum ceilings, cans, and electronic products.

Painted aluminum coils can be divided into fluorocarbon (PVDF) color-coated aluminum coils and polyester (PE) color-coated aluminum coils according to the raw materials of the coating paint.

Painted aluminum coil alloy number

1xxx series: 1060, 1050, 1100, 1070

2xxx series: 2024, 2017, 2014

3xxx series: 3003, 3004, 3105, 3104, 3A21, 3005, 3M03

5xxx series: 5052, 5083, 5182, 5754, 5454, 5005, 5086, 5052A, 5059, 5052B,

6xxx series: 6061, 6063, 6082, 6005, 6101, 6060

7xxx series: 7075, 7005, 7050

The above product models can be produced and provided by MC Aluminum.

Performance advantages of painted aluminum coil:

Colorful: Color-coated aluminum can provide a variety of colors and effects by adjusting the coating material and process.

Good corrosion resistance: the coating protects the aluminum surface from corrosion and prolongs the service life of aluminum.

Good surface quality: The coating can improve the flatness and smoothness of the aluminum surface, and enhance the aesthetics and decoration of the aluminum.

Good wear resistance: The coating can improve the wear resistance of aluminum and reduce scratches and wear on the surface of aluminum.

Convenient construction: color-coated aluminum can be cut, bent and bent according to needs, and has better processing performance.

Good temperature resistance: the melting point of aluminum is 660 degrees, and the general temperature cannot reach its melting point.

Environmental protection: not easy to change color. The use of chrome-free treatment fluids and roller coatings contain active chemical molecules that promote the formation of a protective layer on the surface of the material. Active chemical molecules are stable, easy to recycle, and meet environmental protection requirements.

MC Aluminum specializes in the production of color-coated aluminum coils. The product models are complete and the quality is stable. It can be customized according to customer needs. It is exported globally and has good market feedback. It is favored by major companies and can provide free sample mailing services. Consult product details and For preferential quotation, you can contact us through the form below and email.

Contact Us