1050 3003 5050 aluminum sheet circle are suitable for lighting tools

Aluminum sheet circle materials are widely used in lighting tools. With their lightness, good thermal conductivity, and strong corrosion resistance, they have become an important part of the modern lighting industry. Aluminum circles are often used to make lampshades, lamp cups and other parts. Through deep drawing or stretching, they can be processed into lamp parts of various shapes and sizes to meet different lighting needs.

The alloy numbers of aluminum sheet circles for lighting fixtures include: 1050, 1060, 3003, 5052, 6061, 7075 and other aluminum alloy circles. Aluminum materials with different alloy numbers have different characteristics and are suitable for different lighting tool applications. 1050 and 1060 aluminum alloys are often used in lighting equipment that require excellent thermal conductivity and lower strength, while 3003, 5052 and 6061 are suitable for lighting products that require higher strength and corrosion resistance. Customers can choose to purchase according to their own needs.

Features of aluminum circles for lamps:

1. Excellent thermal conductivity: Aluminum has very good thermal conductivity and can dissipate heat effectively. This makes aluminum circles widely used in lighting tools that require efficient heat dissipation, such as LED lamps.

2. Lightweight: Aluminum materials have a lower density and are much lighter than other metals such as copper and steel, which is particularly important for lighting tools that need to save weight, especially portable lighting equipment.

3. Strong corrosion resistance: The aluminum oxide film naturally formed by aluminum has good corrosion resistance, which can effectively prevent oxidation even in a humid environment and extend the service life of lighting tools.

4. Good processability: Aluminum alloy has good processability and can be formed into various shapes through stamping, cutting, extrusion and other processes to meet the design requirements of different lighting tools.

5. No color difference in anodizing: Aluminum discs that have been anodized not only improve hardness and wear resistance, but also maintain consistent color and enhance the aesthetics of lighting tools.

6. Good surface quality: The surface of aluminum circle is smooth and scratch-free, which makes it very suitable for making lighting tool parts that require high surface quality, such as lampshades, table lamps, floor lamps, etc.

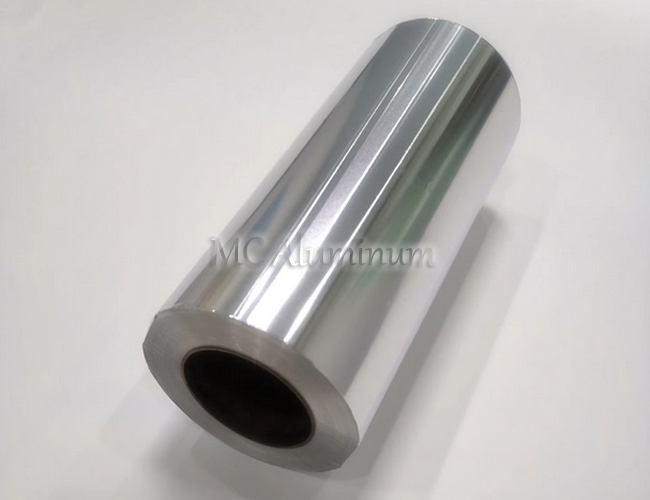

Aluminum circle production process:

1. Aluminum ingot smelting: Aluminum ore or aluminum alloy waste is smelted at high temperature to form aluminum ingots, and strict quality control is carried out.

2. Aluminum alloy casting and extrusion: Aluminum ingots are made into aluminum plates or aluminum strips through casting or extrusion processes, and extrusion can form different shapes.

3. Stamping: Aluminum sheets are processed into round sheets by stamping machines, and the diameter, thickness and surface treatment can be different according to requirements.

4. Surface treatment: Aluminum sheets are treated by anodizing, electroplating, spraying, etc. to enhance appearance and performance, such as corrosion resistance and reflective effect.

5. Precision cutting and processing: Aluminum sheets are precisely cut and drilled according to design requirements to ensure that the size and shape meet product requirements.

Application scenarios:

Lampshade: Aluminum discs are often used as lampshade materials. Their smooth surface and excellent reflective properties can effectively improve the brightness and uniformity of the light. At the same time, their good heat dissipation performance also helps to extend the service life of lighting tools.

Reflectors: Aluminum reflectors are widely used in fluorescent lamp systems and other lighting devices. Aluminum circles can be made into reflectors after processing to reflect light in a directional manner and improve lighting efficiency.

LED lighting equipment: In LED lighting equipment, aluminum circles are often used as heat sinks. LED lamp beads generate a lot of heat when working. Aluminum circles can effectively conduct this heat to the air to prevent the lamp from overheating, thereby extending the service life of the LED lamp.

Decorative parts: Aluminum circles can also be used to make decorative parts of lighting tools, such as frames, brackets, etc. Its stylish appearance and diverse processing properties make lighting tools more beautiful and practical.

Requirements for lampshade aluminum circles:

1. The surface properties of the lampshade aluminum circles are good, without obvious scratches, oil stains, air oxidation, black spots, etc.;

2. When the thickness of the aluminum circle is greater than 1.0mm, the edges of the finished product must be clean and tidy without burrs;

3. Strictly control and test the aluminum alloy, condition and properties of the waterproof coil to ensure the accuracy and diversity of the provided circles;

Contact Us