- sales@alummc.com

- Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

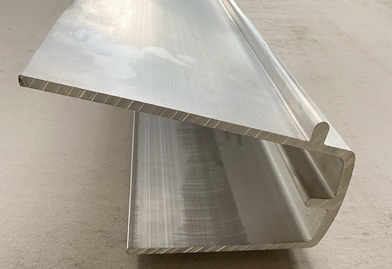

Aluminum fenders, as a kind of ship protection device, are made of aluminum alloy materials. Mainly installed on the side wall or deck edge of the ship, the fender can effectively buffer the impact force when the ship collides and docks, and is used to prevent the hull from being damaged by collision or friction when docking, mooring or contacting other ships and obstacles. The application range of fenders is very wide, suitable for various types of ships, such as passenger ships, cargo ships, tankers, etc. Its materials generally use high-strength steel plates and aluminum alloy plates to ensure that it has sufficient strength and durability.

Aluminum fenders are usually composed of multiple aluminum alloy plates, which are fixed to the hull by welding, bolting, etc. Its interior may be filled with elastic materials (such as rubber, polyurethane, etc.) to enhance its energy absorption effect.

The alloys used for aluminum fenders are mainly 5052 aluminum alloy, 7075 aluminum alloy and 6061 aluminum alloy.

Aluminum alloy fenders have the following advantages:

1. Lightweight and durable: Aluminum alloy materials are lighter than traditional steel fenders, and have excellent corrosion resistance, suitable for seawater environments.

2. Easy to install and maintain: Due to its light weight, aluminum fenders are easier to install and replace, reducing maintenance costs.

3. Strong corrosion resistance: Aluminum fenders perform well in marine environments, can resist salt water corrosion, and extend service life.

4. Beautiful appearance: Aluminum alloy has a good appearance and can be sprayed or treated as needed to make it more decorative.

Application of aluminum fenders:

Aluminum fenders are widely used on various types of ships, including cargo ships, passenger ships, yachts, etc. Especially on high-speed ships, yachts and other ships that require high speed and protection, the application of aluminum fenders is more common.

Q1. What are your payment terms?

A1: T/T 30% as deposit, 70% paid before delivery. We will show you photos of the products and packaging before you pay the balance.

Q2. What are your delivery terms?

A2: EXW, FOB, CFR, CIF, DDU.

Q3. How about your delivery time?

A3: Generally, it takes 25 to 35 days after receiving the advance payment. The specific delivery time depends on the goods and quantity of the order.

Q4. Can you produce according to samples?

A4: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q5. What is your sample policy?

A5: If we have ready parts in stock, we can provide samples, but the customer must pay the sample fee and courier fee.