- sales@alummc.com

- Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

PTP Aluminum Foil (Press Through Packaging Aluminum Foil) is a high-performance aluminum foil material specifically designed for pharmaceutical packaging, primarily used in blister packaging for medications. It effectively protects drugs from moisture, oxidation, and light, extending their shelf life while ensuring stability and safety. PTP aluminum foil is widely used for tablets, capsules, and pills, making it an essential packaging material in the modern pharmaceutical industry.

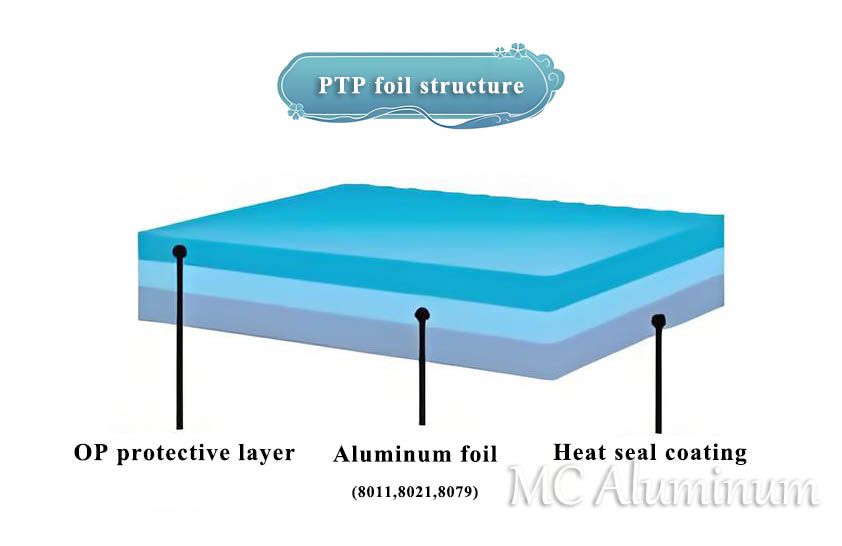

PTP aluminum foil consists of high-purity aluminum foil laminated with polyester or polypropylene plastic film, forming a multi-layer structure that includes:

Protective layer (OP)

Outer printing layer

Aluminum foil base material (AL)

Inner printing layer

Adhesive layer (VC)

Common aluminum alloys for PTP aluminum foil include 8011, 8021, and 8079.

1. 8011 Aluminum Alloy (Standard Pharmaceutical Packaging):

Common tempers: O, H18

High strength, suitable for high-speed packaging equipment

Excellent barrier properties and printability

Used for Aluminum-Plastic blister packaging (PVC + aluminum foil)

2. 8021 Aluminum Alloy (High-End Pharmaceutical Packaging):

Superior barrier properties, providing moisture and oxidation resistance

Good deep-drawing performance

Ideal for Alu-Alu blister packaging

3. 8079 Aluminum Alloy (Reagent & Special Packaging):

Exceptional flexibility, resistant to tearing

Excellent moisture and oxidation resistance

Suitable for medical reagent packaging and specialized pharmaceuticals

1️⃣ Raw Material Selection

Uses high-purity aluminum alloys (8011/8021/8079) to ensure good ductility and corrosion resistance.

2️⃣ Cold Rolling & Annealing

Processed through cold rolling and annealing to achieve the required thickness (0.02-0.03mm) while enhancing mechanical properties.

3️⃣ Surface Coating

Coated with PVC, heat-seal adhesive, and protective lacquer to enhance sealing properties and adaptability.

4️⃣ Printing & Slitting

High-definition printing technology ensures clear patterns.

Precision slitting according to customer specifications.

5️⃣ Quality Inspection

Strict quality control, including pin-hole detection, peel strength tests, and barrier performance tests, ensuring compliance with international standards.

| Project | PTP Blister Foil |

| Thickness | 0.018-0.04mm |

| Temper | Soft |

| Width | 60-600mm |

| Length | Customizable |

| Core ID | 76mm or 152mm |

| Certification | SGS / ISO / CFDA / DMF |

| Printing | Customizable |

| Structure | Paper/AL/VC or PET/AL/VC |

| Application | Blister packaging for tablets, pills, and capsules |

| Packaging | Carton + Pallet |

Chemical Composition of 8011, 8021, 8079 PTP Aluminum Foil (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Remainder |

| 8021 | 0.15 | 1.2-1.7 | 0.05 | - | - | - | - | - | 0.05 | 0.15 | Remainder |

| 8079 | 0.05-0.3 | 07-1.3 | 0.05 | - | - | - | 0.1 | - | 0.05 | 0.15 | Remainder |

Performance Features of PTP Blister Foil

1. Superior Barrier Properties

Effectively blocks gas, moisture, light, and UV radiation, protecting drugs from environmental damage.

2. Excellent Mechanical Strength

Suitable for high-speed pharmaceutical packaging lines, resistant to heat, cold, and corrosion, ensuring stability in various conditions.

3. Outstanding Heat-Sealing Performance

Compatible with PVC, PVDC/PVC, PP, and other plastic-based materials, ensuring an ideal sealing effect.

4. Easy-to-Tear Design

Provides user-friendly accessibility, allowing patients to easily retrieve medications, improving the overall experience.

5. High-Definition Printing Compatibility

Supports monochrome, two-color, or multi-color printing, enabling clear drug identification and enhanced brand image.

6. Safety & Compliance

Manufactured without harmful substances, ensuring pharmaceutical safety.

1.Pharmaceutical Industry:

Used for blister packaging of tablets, capsules, and pills.

2.Nutritional & Health Supplements:

Ideal for vitamins and dietary supplements, ensuring long-term storage stability.

3.Medical Reagent Packaging:

Used for in-vitro diagnostic reagents (IVD) to prevent contamination and oxidation.